This invention relates to a compact rod/pipe cutter featuring a triangular frame with one hinged, one collapsible limb connected to a handle design that delivers high mechanical advantage using fewer, simpler components. Its integrated dual-shearing mechanism ensures clean, burr-free cuts while reducing size and weight—ideal for surgical use where space and sterilization constraints are critical. The design enhances portability, ease of use, and cost-efficiency, making it well-suited for healthcare and industrial applications.

Conventional shearing pipe/rod cutters are bulky, complex, and require significant force to operate, limiting their usability in surgical settings. They are difficult to sterilize due to their large size and are often expensive and non-portable. A compact, high mechanical advantage cutter is needed for easy, efficient, and sterile use, especially in orthopedic surgeries.

- High Mechanical Advantage: The cutter provides high mechanical advantage by converting large handle rotation into small shearing displacement, generating high cutting force with smooth, burr free rod surface.

- Compact and Lightweight: It has few components, compact geometry, and optional detachable handle to reduce volume for storage, transport, and sterilization.

- Equal Force Throughout Operation: The threaded mechanism ensures effort to rotate the handle remains constant, regardless of cutting resistance.

- Customizable Construction: Geometries of limbs, holes (circular, square, rectangular), hinges, and shearing components can be modified while retaining the functional principle.

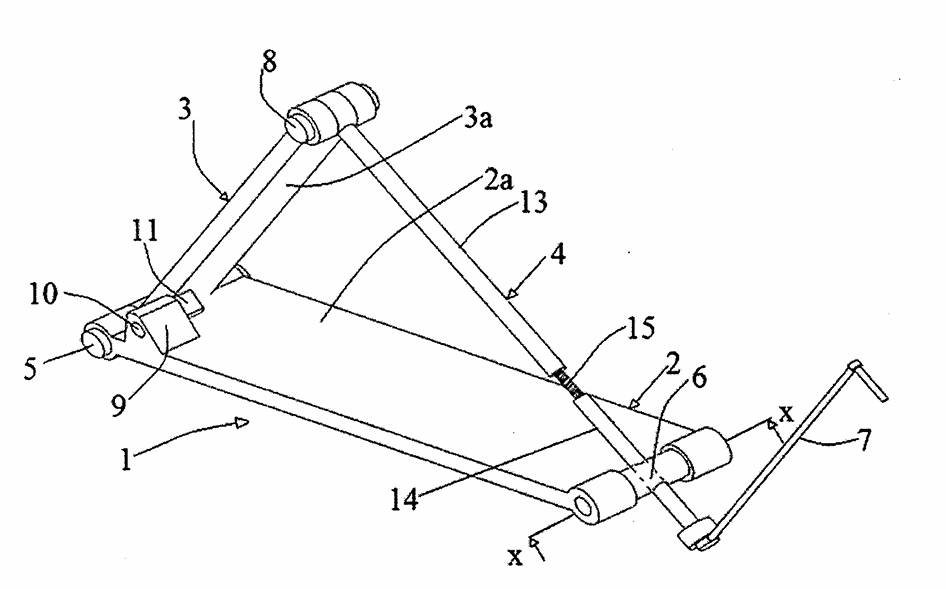

The rod cutter consists of a triangular frame formed by a base, a rigid side limb, and a collapsible side limb, designed as an isosceles triangle for structural efficiency. The rigid limb is hinged to one end of the base, while the collapsible limb is rotatably mounted at the opposite end and connected to a handle. The free ends of both limbs are hinged together, enabling contraction and expansion of the frame. A first shearing element with a rod feed hole is mounted on the base, while a smaller second shearing element with a feed hole is attached beneath the rigid limb. The collapsible limb comprises two threaded cylindrical members that enable linear motion through rotation, generating a powerful shearing action with minimal effort and ensuring compactness and mechanical advantage.

1

The compact, low-effort rod cutter enhances accessibility to precision cutting in industries such as construction, surgery, and manufacturing. Its ergonomic and efficient design reduces physical strain, enabling safer manual operation and promoting workforce inclusivity, especially for individuals with lower physical strength. By minimizing equipment size and maximizing mechanical advantage, it contributes to cost-effective infrastructure development and supports medical advancements.

- Surgical and Medical device industry

- Defense and Aerospace

- Automotive industry

- Manufacturing industry

Geography of IP

Type of IP

1319/MUM/2012

389360