This patent presents a single-step, chemical-free method to fabricate titanium suboxides (TSO) by creating laser-induced oxygen vacancies on TiO2-doped polymer sheets using a CO2 infrared laser. The TSO formation is confirmed through XPS, XRD, and XAFS characterization techniques. The study explores the impact of laser settings, such as power and image density, on the reduction of TiO2 to TSO, offering a direct and efficient synthesis route for applications in electro-catalysis and photo-catalysis.

The problem with traditional methods for fabricating titanium suboxides (TSO) lies in their high- temperature, multi-step processes, which are expensive, environmentally challenging, and limit the widespread application of these materials. We need a more efficient, cost-effective method to produce TSO.

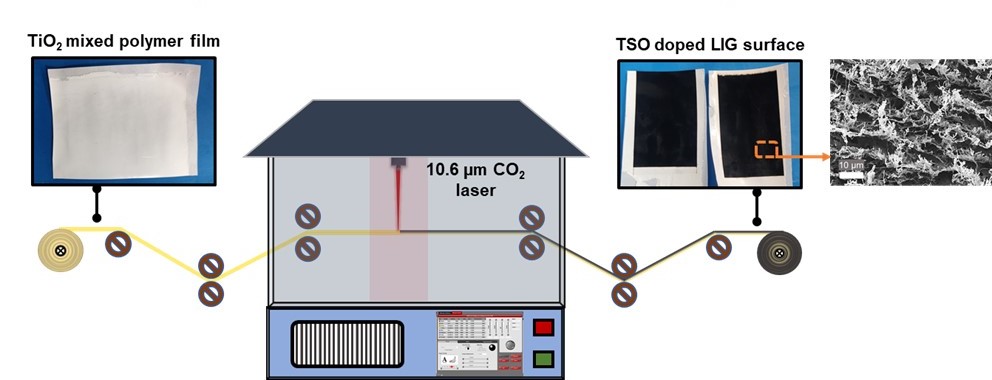

- Single-Step Process: This invention presents a method for fabricating titanium suboxide (TSO)-graphene composites in a single step, thereby reducing complexity, by preparing TiO2-doped polymer sheets and using CO2 infrared laser irradiation to convert TiO2 into TSO and form graphene.

- Chemical-Free Method: It uses laser irradiation without the need for chemical reductants. The preparation involves dissolving Polyether Sulfone (PES) powder in dichloromethane (DCM), mixing with TiO2 powder, and controlling DCM evaporation to create sheets of approximately 120 ± 5 µm thickness. Laser irradiation is performed in the presence of air with specific laser settings (PPI of 140, 15% power, 25% speed, and image density of 6). This method produces TSO-graphene composite sheets, which can be utilized to create laser-induced TSO-graphene composite electrodes.

- Cost-Effective: This process eliminates the need for high-temperature furnaces and multi-step processes.

- Rapid Fabrication: It achieves quick conversion of TiO2 to TSO with instantaneous photothermal heating.

The prototype involves using a CO2 infrared laser to create titanium suboxide (TSO) by inducing oxygen vacancies on TiO2 doped polymer sheets. The process includes preparing the polymer sheets, laser irradiation with specific settings, and characterizing the TSO using XPS (X-ray Photoelectron Spectroscopy). TSO electrodes are fabricated for electrochemical applications like dye degradation and virus inactivation, demonstrating the effectiveness of the laser-induced TSO.

Demonstration and/or validation has been done in the lab environment.

6

The technology improves clean water access by enhancing purification processes, resulting in safer drinking water and a reduction in waterborne diseases. It also contributes to environmental protection by strengthening pollution control measures, leading to a cleaner and healthier environment. It supports sustainable energy development by increasing the efficiency and durability of renewable energy systems. In addition, it promotes public health by facilitating virus inactivation and reducing environmental pollutants.

- Water Purification: Electro-catalytic and photo-catalytic removal of organic dyes and viruses

- Renewable Energy: Enhances solar cells and energy storage devices

- Pollution Control: Catalysts for air and water purification

- Electronics: Improves sensors, displays, and semiconductors

- Electrochemical Devices: Produces high-conductivity electrodes for batteries and supercapacitors

Geography of IP

Type of IP

202221014832

426680