Scientists from IIT Bombay devise a method to grow nanographene on copper using atomic hydrogen at lower temperatures.

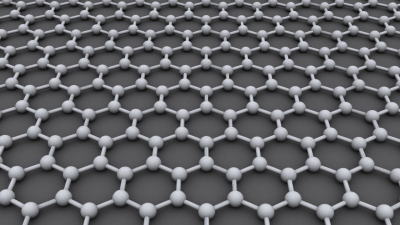

Graphene, a two-dimensional, sheet-like variant of carbon, is a much sought-after material in science and engineering. Scientists are not only trying to explore and exploit its properties but are also looking for efficient and cost-effective methods to produce it. In a recent study, Prof Rajiv Dusane and Dr Shilpa Ramakrishna from the Indian Institute of Technology Bombay (IIT Bombay) have devised a new method to grow nanographene films on a copper foil with the help of atomic hydrogen at relatively lower temperatures compared to conventional methods.

Since its first unambiguous synthesis and identification in 2004, graphene has been widely studied since it has exceptional mechanical and electrical properties. One of the primary techniques used to synthesize graphene is the chemical vapour deposition where a carbon-containing compound like methane is exposed to temperatures as high as 1000℃. Due to the heat, the carbon atoms break free and get deposited on a substrate plate. Copper is mostly used as the substrate because of its desirable thermal properties.

However, a significant disadvantage of this method is that the substrate also needs to be maintained at high temperatures. "The high temperature does not allow the use of other types of materials as substrates. Also, processes involving high temperatures demand a high cost of instrumentation and maintenance," explains Dr Shilpa. But, bringing down the temperature is not an option because, at lower substrate temperatures, the deposit will remain as amorphous carbon and not crystallize into graphene.

Previous studies had reported the crucial role played by atomic hydrogen in the deposition of diamond films and polymeric films over a given substrate. Taking a cue, the researchers of this study, published in the journal Materials Chemistry and Physics, decided to employ a similar technique. Instead of setting a high temperature for the copper substrate, they kept it at 600℃ and placed tungsten filament heated to 2000℃ above it. They then passed methane gas through this assembly, which resulted in the deposition of a layer of amorphous carbon on the copper substrate. Hydrogen gas was then passed over the filament, where the hydrogen atoms split and interacted with the amorphous carbon, leading to its conversion into graphene.

The method proposed by the researchers is called 'hot wire chemical vapour deposition' and is better than traditional methods on many counts. Since the dissociation or splitting of the methane molecules is very efficient, the required concentration of gas compared to conventional methods is significantly less. Also, the heated filament consumes less power, thereby considerably reducing the otherwise high substrate temperature required for graphene growth. These factors, in turn, bring down the overall cost of production as well.

A nanoscale study of the produced graphene showed that it is possible to control the growth of graphene by varying the exposure time and concentration of hydrogen. This finding could help potential studies that explore the use of atomic hydrogen chemistry, instead of just substrate-carbon interaction, to tailor the properties of graphene film at the nanoscale.

In the future, Prof. Dusane and his team plan to devise a more comprehensive method for synthesising graphene. “Utilising the chemistry of atomic hydrogen, we plan to devise a further improved methodology to grow graphene at low temperature using hot wire chemical vapour process,” says Prof. Dusane.

Prof. R O Dusane