An Improved Process for Water Treatment to Remove Arsenic, Iron and Phosphate

It is an innovative water treatment process that addresses the urgent issue of groundwater arsenic, iron, and phosphate contamination. It integrates a reactor with a zero-valent iron (ZVI) unit and a filtration system designed to remove these contaminants effectively through co-precipitation and co-oxidation. The technology is particularly significant due to its efficiency in meeting stringent WHO guidelines for drinking water, its adaptability for both small and large-scale applications, and its user-friendly, low-maintenance operation.

Existing water treatment methods face significant challenges in effectively removing contaminants like arsenic, iron, and phosphate from groundwater, especially to meet the stringent WHO drinking water guidelines of arsenic levels below ten ppb. In regions like West Bengal and Bangladesh, arsenic levels in groundwater pose serious health risks, including skin lesions, cancer, and cardiovascular and neurological disorders.

- Co-precipitation and Co-oxidation: It employs a unique two-pronged approach: Co-precipitation(forms insoluble iron hydroxide complexes that are easily removed) and Co-oxidation (makes the arsenic more readily adsorbed)

- Uncontrolled Zero Valent Iron (ZVI) Leaching: The reactor carefully manages the release of iron ions into the water by Direct Leaching.

- ZVI Unit Design: Ensures even water flow, prevents clogging and adjustable unit height for varying water conditions.

- Simplified Cleaning Process: Targeted cleaning using a flexible pipe assembly through designated ports

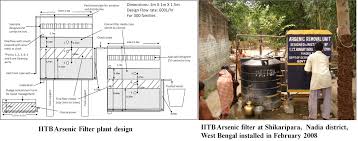

The reactor comprises two key components: a zero-valent iron (ZVI) unit and a gravel filtration bed. The ZVI unit can operate with or without an electric current. In the absence of electricity, it consists of an iron tray with overflow pipes covered by conical lids, promoting iron leaching into the water. The subsequent gravel filtration bed captures the resulting iron hydroxide floccules, which effectively adsorb arsenic, iron, and phosphate contaminants from the water. It consistently reduces arsenic levels below the WHO guideline of 10 ppb, even with initial concentrations ranging from 300 to 1000 ppb. This robust and user-friendly technology operates effectively with water exhibiting typical groundwater characteristics, including pH levels between 6.5 and 8.3, arsenic concentrations up to 0.5 mg/L, phosphate concentrations up to 3 mg/L, and iron concentrations up to 10 mg/L. The system can be easily scaled to serve communities of various sizes. The filtration bed can be easily cleaned by flushing water through a flexible pipe assembly inserted through designated cleaning ports, simplifying maintenance and reducing downtime.

It has a potential to significantly impact communities suffering from arsenic, iron, and phosphate contamination in groundwater. The reactor’s simplicity, robustness, and cost-effectiveness make it particularly suitable for rural areas in developing nations where existing high-tech solutions are impractical. The technology directly addresses the pressing social challenge of providing safe drinking water, thereby mitigating health risks and improving the overall quality of life for millions.

This technology relates to water treatment, specifically the removal of contaminants such as arsenic, iron, and phosphate from groundwater. It utilizes a reactor system with a zero-valent iron unit for co-precipitation and co-oxidation reactions, followed by gravel filtration to eliminate these contaminants. This technology is primarily designed for rural areas, particularly in areas with high arsenic levels in groundwater. It might also find use in agricultural settings for removing excess iron and phosphate from irrigation water. In essence, this technology offers a solution for various water purification challenges where the removal of specific contaminants is crucial.