This innovation provides a method for manufacturing a lightweight and high strength Connecting Rod (CR) using sheet metal forming techniques. The process begins with selecting and processing a suitable material, followed by heating it to a hot stamping temperature. The heated sheet is then placed on a die to deform and form a shallow section with at least two flanged holes. Rapid quenching is applied to retain material strength and dimensional accuracy. The outer area of the deformed section is trimmed to ensure uniform flange height. The final connecting rod is produced by joining two deformed sheet halves using either a surface-to-surface or a peripheral joining technique.

Conventional forged connecting rods are complex to manufacture and involve multiple steps. They also face high stress at both ends during engine operation, requiring high strength. Traditional methods are time-consuming and material-intensive. There is a need for a simpler, stronger, and more efficient manufacturing process.

- High Structural Strength: The use of 22MnB5 as a workpiece material which has high strength to weight ratio at room temperature, hot formed parts that have higher stiffness and strength than cold-formed or bent sheet metal rods provide great structural strength; tested under tensile, compressive, buckling, and dynamic loads.

- Significant Weight Reduction: The hollow connecting rod design and high strength to weight ratio of 22MnB5 ensures upto 30% weight reduction compared to conventional forged connecting rod, thus also improving fuel efficiency due to less inertial (mass) of engine.

- Streamlined and Less Complex Manufacturing Process: The conventional systems require multiple steps to attain the required shape. Unlike the conventional system, the present disclosure, uses the single step forming process to make the half connecting rod. The two parts can be joined together to attain the final shape.

- Reduced Production Time: Single-step forming reduces total cycle time benefits faster production without compromising the strength.

The invention is a method to make connecting rods.

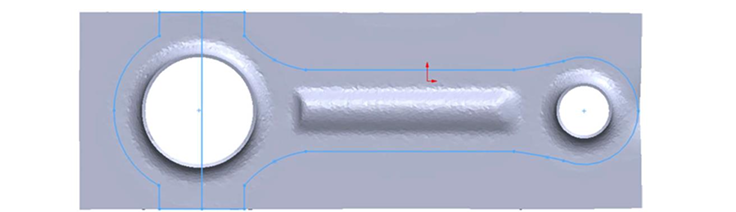

One example of rod: The prototype consists of a two-part hollow connecting rod made using hot stamping steel 22MnB5. Each half is formed using a single-step process that includes hole flanging and hot embossing at elevated temperatures, followed by rapid quenching to achieve high strength. The formed halves are then trimmed to uniform flange height and are then joined using surface-to-surface contact welding to form the final component.

3

This innovative method and design promote energy efficiency by reducing vehicle weight, leading to lower fuel consumption and emissions. Additionally, simplified manufacturing processes can boost production rate increasing the efficiency of Manufacturing industries.

- Automotive and Transportation

- Agricultural machinery

- Power generation equipment (e.g., generators and engines)

- Aerospace and Defense

- Marine engines manufacturing

Geography of IP

Type of IP

202323004430

547457