This innovation relates to a method for manufacturing a lightweight piston from a metallic sheet to improve fuel efficiency in internal combustion engines. The process involves selecting a suitable metallic sheet of predefined diameter(blank), drawing it into a cup through a first die, followed by redrawing with a second die to refine the shape. The cup is then passed through an ironing die to achieve the desired uniform wall thickness. Finally, flanged holes are created on the cylindrical surface of the cup to reduce weight and improve structural strength and also help in assembling or fixing other components. This lightweight piston contributes to overall engine weight reduction, enhancing fuel efficiency and reducing emissions.

Conventional pistons are heavy and contribute to higher fuel consumption. While some engine parts have been light-weighted using composites, pistons remain largely unchanged. There is a need for a lightweight piston made from metallic sheets to reduce engine weight and improve fuel efficiency.

- Improved Fuel Economy and Reduced Emission: The piston is made from a lightweight metallic sheet (Al-SiC, Al-Alumina, or Al-Ti alloy) rather than traditional casting or forging methods, significantly reducing its weight. Weight reduction helps in lower fuel consumption due to reduced inertia(mass) and load on engine components and therefore also reducing emissions.

- Integrated Flanged Holes: Flange holes reinforce the hole area without adding bulk and also increase structural integrity besides helping in assembling other components like gudgeon pin (piston pin).

- Faster Production Rate: Drawing and Ironing are fast, repeatable processes suitable for mass production.

- Cost-effective Manufacturing: The use of sheet metal and Drawing, Ironing manufacturing processes reduces material and production costs.

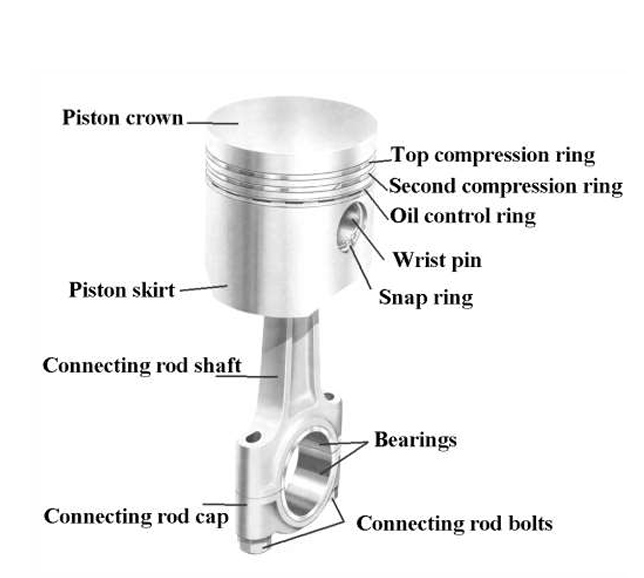

The piston is made from lightweight metal sheets like Al-SiC or Al-Ti alloy, drawn and redrawn into shape. The wall thickness is finalized by ironing. It includes a piston crown, an external cylinder surface of the piston, comprising grooves for installing piston skirt, a top compression ring, second compression ring, and oil control ring. Two diametrically opposite flanged holes are provided for the piston pin, with a bearing for connecting rod assembly.

4

This innovation promotes fuel efficiency by reducing overall engine weight, which directly contributes to lower fuel consumption and reduced greenhouse gas emissions. It supports the development of more sustainable and eco-friendly vehicles.

- Automotive industry

- Aerospace industry

- Two-wheeler and Small engine manufacturing

- Agricultural machinery

- Industrial engine manufacturing

Geography of IP

Type of IP

202222039108

551574