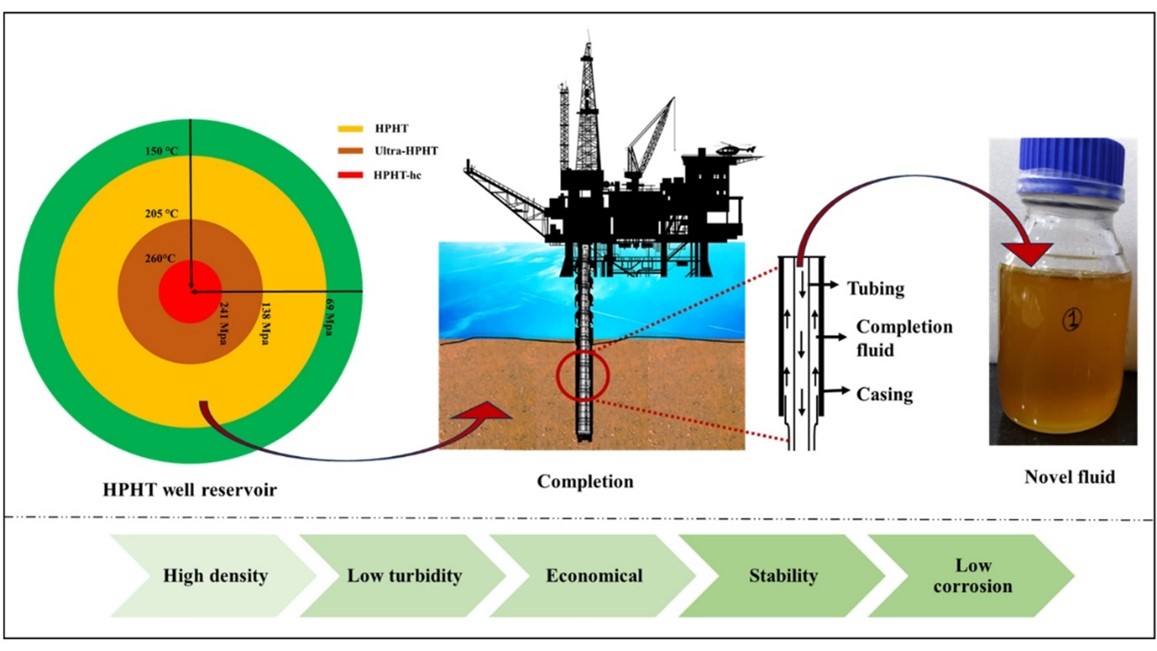

The invention provides an advanced completion fluid specifically designed for ultra-high pressure and high temperature (ultra-HPHT) oil and gas wells. This new fluid, comprising an organic salt, an inorganic salt, and two additives (a chelating agent and a stabilizer), offers high density, low corrosion, thermal stability, low turbidity, and long-term storage stability. It addresses the limitations of traditional completion fluids, enhancing wellbore stability, reducing equipment degradation, and improving the efficiency and safety of extraction processes under extreme conditions.

- High Density: Ensures stability and prevents wellbore collapse in extreme conditions.

- Low Corrosion: Reduces equipment degradation and maintenance costs.

- High Thermal Stability: Maintains effectiveness under extreme heat.

- Low Turbidity: Minimizes clogging of reservoir pores.

- Long-Term Storage Stability: Remains effective over extended periods.

- Enhanced Debris Carrying Capacity: Improves efficiency in removing drilling debris.

- High Density: Ensures stability and prevents wellbore collapse in extreme conditions.

- Low Corrosion: Reduces equipment degradation and maintenance costs.

- High Thermal Stability: Maintains effectiveness under extreme heat.

- Low Turbidity: Minimizes clogging of reservoir pores.

- Long-Term Storage Stability: Remains effective over extended periods.

- Enhanced Debris Carrying Capacity: Improves efficiency in removing drilling debris.

- Composition Optimization: Prototypes have been formulated with precise ratios of organic salt, inorganic salt, chelating agent, and stabilizer.

- Performance Validation: Lab testing confirms the prototype's high density, low corrosion rate, thermal stability, and low turbidity under simulated ultra-HPHT conditions.

Technology is at the stage of demonstration and validation in a laboratory environment. Researchers are focused on testing and refining the composition of the new completion fluid. They are conducting experiments to validate its performance characteristics, such as high density, low corrosion, thermal stability, turbidity, and storage stability, under simulated ultra-high pressure and high temperature conditions. This phase involves optimizing the mixture ratios and ensuring the fluid meets all desired properties before it can be scaled up for field testing and potential commercial use.

4

- Enhanced Energy Efficiency: Improves oil and gas extraction, meeting energy demands more effectively.

- Reduced Environmental Impact: Minimizes equipment corrosion and reservoir damage, leading to more sustainable drilling practices.

Oil and Gas industries such as ONGC, Petroleum Engineering, Chemical Manufacturing, Environmental Protection

- Wellbore Stabilization: Used to maintain structural integrity during drilling and completion in ultra-HPHT conditions.

- Debris Removal: Facilitates efficient removal of drilling debris to enhance oil and gas recovery operations.

202211049373

429846