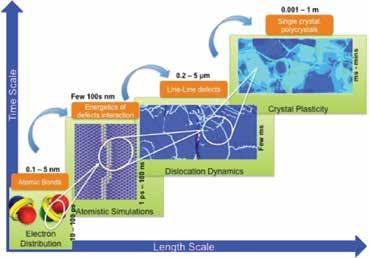

Integrated computational materials engineering (ICME) has two key components namely multi-scale modeling beginning with first principles and data informatics for better design of products. Both components are focused on shortercycle of product development and efficient use of materials and resources leading to lower cost of manufacturing.‘Integrated’ means integration of interdisciplinary technology to desired product via multi-scale qmodeling. In the ‘bottom-up’ approach of ICME one starts from first principles, designs a material for a given application. In the ‘top-down’ approach, data informatics may be employed for finding all the possible materials and logistics for manufacturing a product for applications of interest. By linking the available information it is possible to figure out process-structure-property relations that are critical to the successful implementation of ICME. Over the years product design and manufacturingtechnology have evolved to superior counterpartsvia sophisticated computational tools. Competitive computational materials engineering tools are required for keeping pace with product design and manufacturing. ICME ecosystem intends to make the manufacturing and troubleshooting of in-service engineering components more efficient. The overall toolset encompassing ICME has sophisticated computational and visualisation tools.Given the size and complexity of multi-scale domain of ICME, computational methods are generally massively parallel.Computational materials engineering is the backbone of ICME and connects science to product design and manufacturing. Materials mechanisms that take place during various stages of processing differ depending on length and time scales of process. There is no physically based model that captures all the mechanisms seamlessly. Thus the gaps between time and length scales are often filled with experimental data and empirical models or both. Such links are key to the success of ICME. Precisely the ultimate goal of ICME is to let the stakeholders know about all that is involved in product manufacturing even before the manufacturing starts. Such information includes raw material, process recipe, product design, living and non-living machinery to be used and relevant data informatics. If a certain change occurs in application, ICME toolsets must be able to recommend the required changes at any stage of process. Our research group is developing in-house materials physics based computational models that are relevant to ICME. Overall the computational part includes continuum mechanics and materials science & engineering. Apart from material physics, other challenges are computational methods, analysis of large dataset and representation. We are paying more attention to bridged multi-scale models since they show promise for cost effective solution to material design (refer figure). One of the currently undertaken research work utilising the concept of ICME is Development of Lightweight High Performance Metal Multilayer Composites. These high performance metals are targeted for automotive, aerospace, transportation and defense domains. For more information, visit www.icmeresearch.in.

Prof. Alankar Alankar