The invention provides a flexible tactile sensor for object detection that incorporates a piezoelectric polyvinylidene fluoride (PVDF) film prepared via a spray-assisted immersion precipitation (SAIP) method. This process enables in-situ formation of the electroactive β-phase during fabrication without requiring additional treatments such as mechanical stretching, annealing, or poling. The sensor features a hemispherical dome structure made of PVDF, which enhances mechanical adaptability and pressure sensitivity. The device is capable of detecting directional force and generating distinct voltage responses corresponding to applied pressure. This innovation offers a scalable, low-cost, and environmentally benign route for developing flexible tactile sensors with potential applications in robotics, wearable electronics, and biomedical systems.

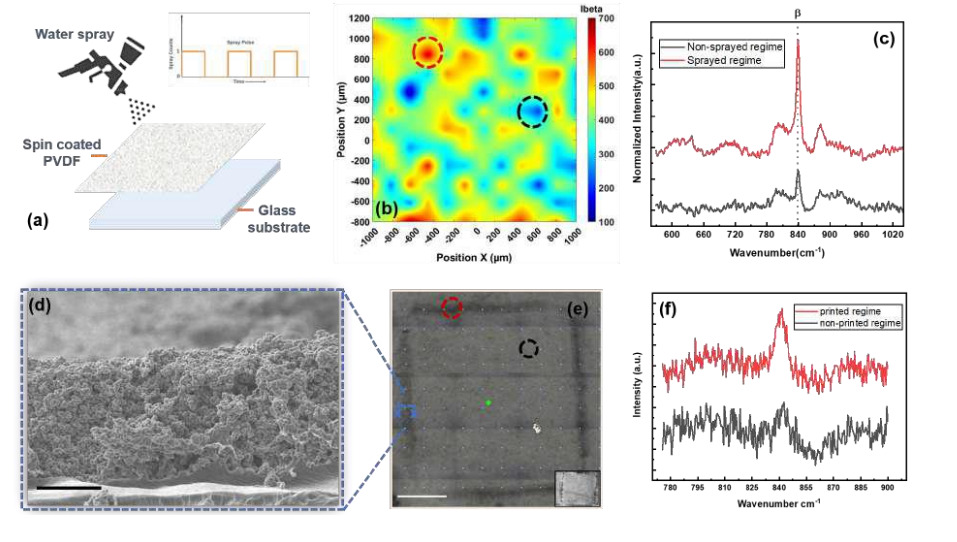

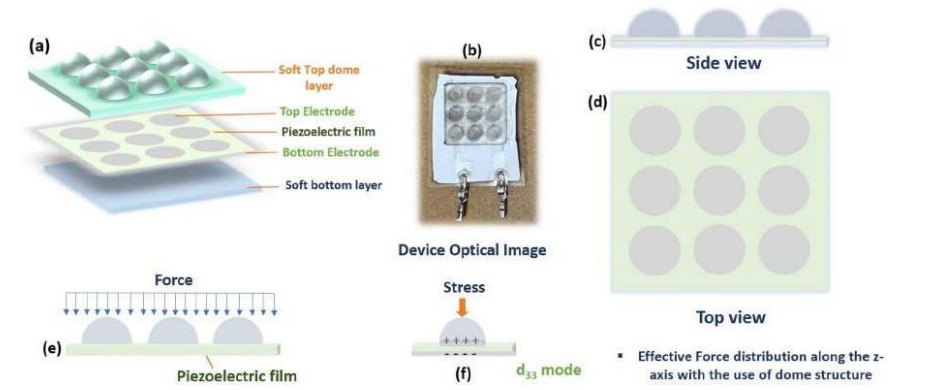

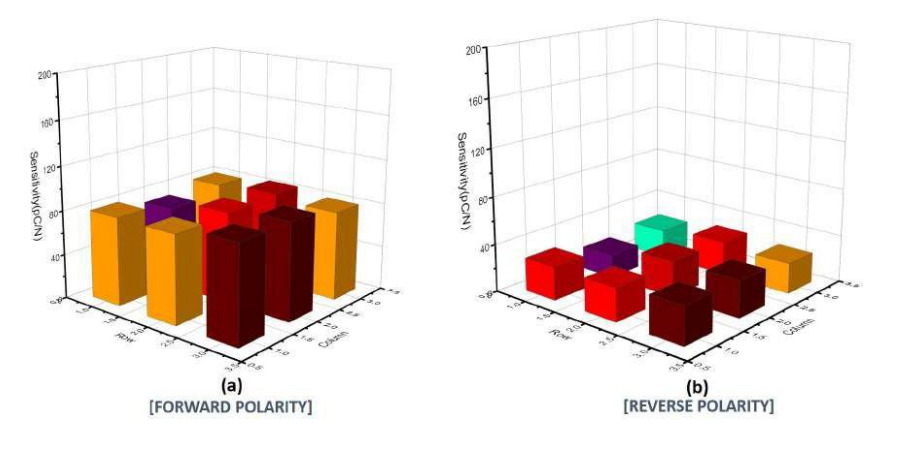

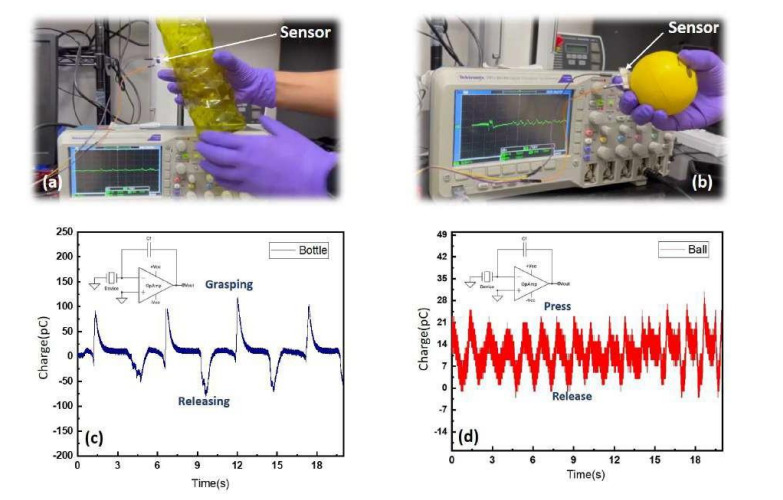

Figure (1a) Schematic representation of spray assisted immersion with inset showing spraying criteria, (1b) Raman mapping of β-phase intensity in a large area of spray treated sample with marked red circle representing the higher Iβ and black circle representing non-sprayed regime with lower Iβ, (1c) Raman spectra for the sprayed and non-sprayed regime, (1d) Cross sectional micrograph showing slow-demixing crystalline growth achieved via inkjet printing of water, (1e) Optical image showing inkjet printing of water of viscous PVDF film with pattern marked in a square, red and black circle representing the area of data acquisition for comparative study and (1f) Comparative Raman pattern at the water printing regime and non-printed regime signifying a potential in developing polarized zones in the PVDF matrix; (2a) Complete architecture of the tactile sensor arrays, showing arrangements of different layers, (2b) Optical image of the developed sensor, (2c) Schematic representation of the side view for the sensor, (2d) Top view of the arranged electrodes, (2e) Force distribution on the sensor due to the presence of PDMS domes, and (2f) Working of sensor in d33 mode; (3) The sensitivity map of SATS in (3a) forward polarity and (3b) reverse polarity; (4a) Optical image showing the operation of the sensor as it comes in contact with the plastic bottle with the inset showing the charge amplifier circuit, (4b) Optical image of the sensor pressing a compressible rubber ball with the inset showing the charge amplifier circuit used, (4c) Charge characteristics with respect to time as sensor grasp and release the plastic water bottle, and (4d) Charge characteristics obtained via pressing and releasing of the ball.

Existing tactile sensors often suffer from limited mechanical flexibility, low sensitivity, and complex fabrication techniques, which hinder their application in conformal electronics and robotic sensing systems. Conventional piezoelectric sensors made from polyvinylidene fluoride (PVDF) require additional treatments like mechanical stretching, annealing, or electrical poling to induce the β-phase necessary for piezoelectric activity. These methods are time-consuming, energy-intensive, and lack control over phase formation during film fabrication. Moreover, many current sensors rely on flat geometries, which restrict spatial pressure mapping and reduce the directional sensitivity essential for accurate object detection. Therefore, there is a need for a scalable and simplified process to fabricate flexible, β-phase-rich PVDF-based tactile sensors that can provide enhanced piezoelectric response, mechanical adaptability, and multidirectional sensitivity for real-time object detection applications.

- Single-Step β-Phase Formation: The sensor uses a spray-assisted immersion precipitation (SAIP) method to induce β-phase crystallinity in PVDF directly during film formation, eliminating the need for post-treatment.

- Enhanced Sensor Geometry: A hemispherical dome structure is integrated into the sensor to increase surface adaptability and enable accurate detection of directional pressure variations.

- Low-Cost and Scalable Fabrication: The use of simple spraying and immersion steps without thermal stretching or mechanical alignment enables mass production with minimal infrastructure.

- High Piezoelectric Output: The developed PVDF film demonstrates improved voltage generation under applied force, enhancing signal sensitivity for real-time object detection.

- Environmentally Friendly: The entire fabrication is carried out using water-based solvents at room temperature, ensuring safety, sustainability, and compatibility with green manufacturing practices.

The prototype tactile sensor was fabricated using a spray-assisted immersion precipitation (SAIP) method wherein a PVDF solution was sprayed over a non-solvent bath comprising water or ethanol. This one-step process resulted in the in-situ formation of β-phase-rich PVDF films. The film was shaped into a hemispherical dome and mounted on an interdigital electrode (IDE) patterned on a flexible substrate. The sensor demonstrated measurable piezoelectric output under mechanical pressure and was tested for force response and object detection sensitivity. Performance evaluation confirmed the generation of direction-dependent voltage signals upon physical interaction, validating the effectiveness of the sensor design and fabrication process.

The technology has been demonstrated at the laboratory scale with successful fabrication of flexible, β-phase-rich PVDF dome-shaped sensors using the spray-assisted immersion precipitation (SAIP) method. Functional prototypes have been developed and tested for pressure sensitivity, directional response, and voltage output under mechanical deformation, confirming their applicability in object detection and tactile sensing applications.

3

The invention provides a low-cost, scalable, and environmentally friendly tactile sensing technology that can be integrated into wearable electronics, assistive devices, and robotic systems. By enabling real-time detection of physical interactions through flexible and sensitive sensors, it supports advancements in healthcare monitoring, prosthetic feedback systems, and human–machine interfaces, thereby improving accessibility, safety, and quality of life in both clinical and daily-use environments.

- Robotics and Automation: Enables sensitive touch interfaces and object detection in robotic arms and grippers

- Wearable Electronics: Integrates into smart textiles and health monitoring bands for real-time pressure sensing

- Prosthetics and Assistive Devices: Enhances feedback systems in artificial limbs by mimicking human tactile response

- Biomedical Devices: Supports flexible sensor patches for detecting physiological parameters through mechanical stimuli

- Human-Machine Interfaces (HMI): Improves touch-based interfaces for next-generation electronic devices

- Flexible and Printed Electronics Industry: Applies in manufacturing conformable sensor arrays and e-skin systems

- Consumer Electronics: Useful in touch-sensitive surfaces and interactive electronics requiring force mapping

Geography of IP

Type of IP

202421007080

565516