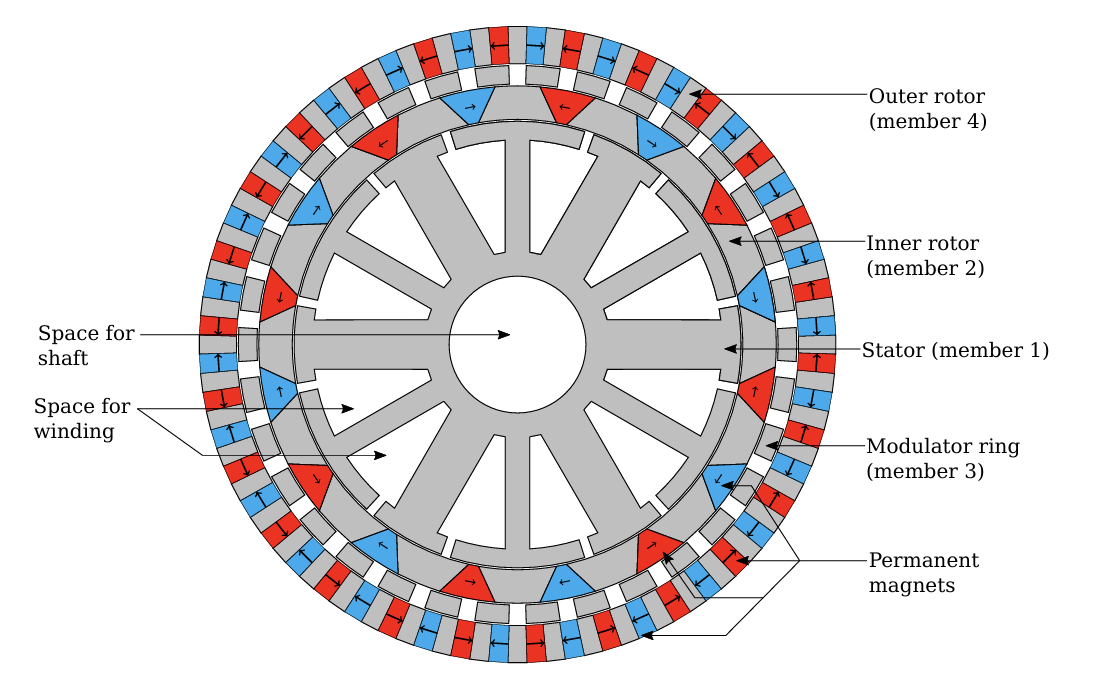

The invention integrates a magnetic gear with a Segmented Rotor Switched Reluctance Motor (SSRM) to create a high-torque density motor suitable for various applications such as electric vehicle in-wheel drives, marine propulsion, eVTOL aircraft, and renewable energy generation. This compact system combines a Flux-Focusing Magnetic Gear (FFMG) with an SSRM, where the rotor segments with permanent magnets serve both motor and gear functions. The stator is housed inside the rotor, and a modulator ring coupling between the members of the magnetic gear. This design enhances torque density by generating both reluctance and magnet torque, while reducing costs by using the same magnets for motoring and gearing, making it an efficient, cost-effective solution for high-torque applications.

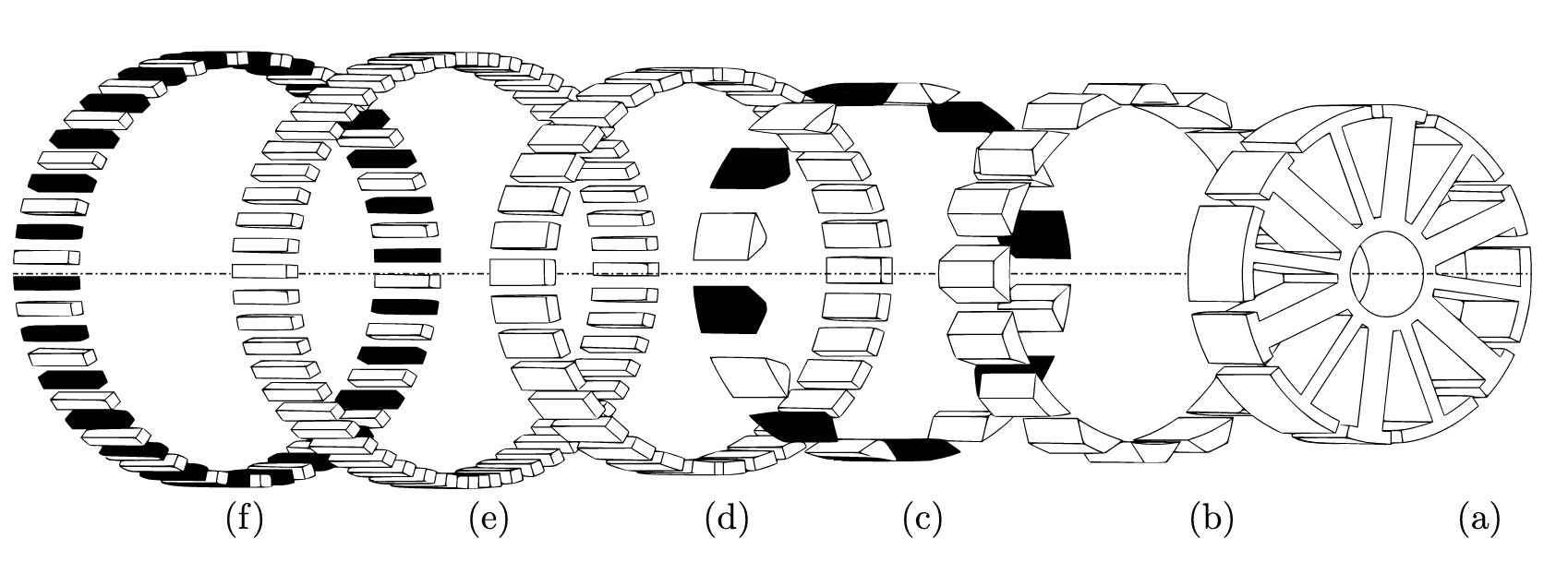

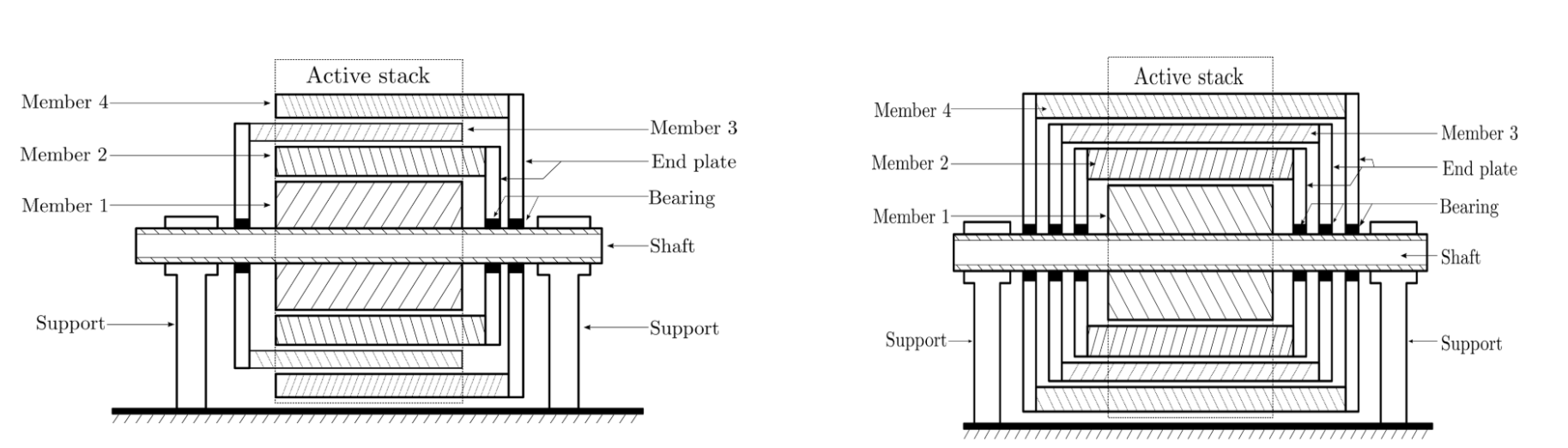

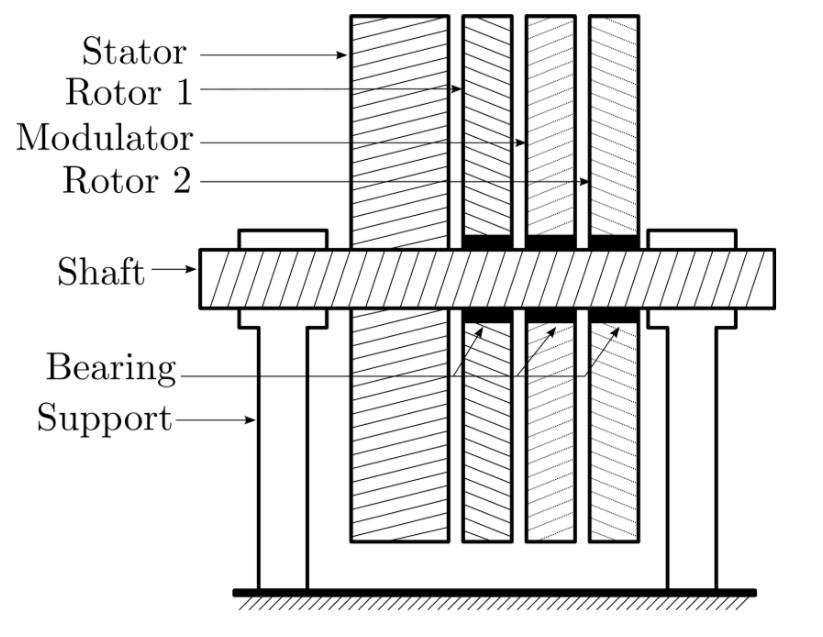

Figure [1] Cross-section of the invented gear integrated motor; [2] Assembly of the gear integrated motor (a) Stator of the SSRM (member 1) (b) Iron poles of the rotor of SSRM cum the inner rotor of the magnetic gear (member 2) (c) Permanent magnet poles of the rotor of SSRM cum the inner rotor of the magnetic gear (member 2) (d) Modulator ring (member 3) (e) Iron poles of the rotor of SSRM cum the inner rotor of the magnetic gear (member 4) (f) Permanent magnet poles of the rotor of SSRM cum the inner rotor of the magnetic gear (member 4); [3] Possible mechanical assembly of the members in the radial flux configuration; [4] Possible mechanical assembly of the members in the axial flux configuration

The objective is to create a compact, high-torque density motor suitable for low-speed applications, including in-wheel drives, fans, marine propulsion, Electric Vertical Take-Off and Landing (eVTOL), and renewable energy generation. The goal is to integrate a Magnetic Gear (MG) with a Segmented Rotor Switched Reluctance Motor (SSRM) to improve torque density and efficiency while eliminating the need for separate gearboxes and ensuring seamless coupling of the motor and the gear without using any coupling member.

- Integration of SSRM and MG: The design co-axially integrates SSRM with flux-focusing MG, eliminating separate gearboxes, and is ideal for in-wheel drives and marine propulsion.

- Dual-Purpose Rotor: The high-speed rotor with permanent magnets functions as SSRM and MG rotor, developing additional reactance torque along with reluctance torque.

- Concentric Arrangement: Four members are arranged concentrically and radially outward as (i) the stator, (ii) the high speed rotor, (iii) the modulator ring, and (iv) the outer rotor.

- Multiple Air-Gaps: Three air-gaps facilitate efficient magnetic flux modulation and torque transfer, for low-speed high-torque applications.

- Versatile Operating Modes: The motor supports various operating modes, suitable for applications needing Continuously Variable Transmission (CVT).

- Axial and Radial Flux: It is configurable in axial and radial flux setups, adaptable for large vehicles or wind power generators.

- High Torque Density: It uses same permanent magnets (PM) for motoring and gearing, enhancing torque density and cost-effectiveness by increasing PM utilization for electric vehicles and renewable energy.

NA

The magnetic gear integrated segmented rotor switched reluctance motor has reached proof-of-concept stage. A more efficient and torque dense version of the same has been developed, which is currently being manufactured for experimentation.

3

The innovation promotes the use of electric vehicles by providing efficient, high-torque motors, contributing to reduced greenhouse gas emissions and lower dependency on fossil fuels. It facilitates the development of eVTOL vehicles and other innovative transportation methods, potentially transforming urban mobility and reducing traffic congestion.

It advances renewable energy technologies like wind and tidal power generation, aiding in the transition to sustainable energy sources and reducing environmental impact.

It enhances capabilities in industries requiring high-torque, low-speed motors, leading to improvements in productivity and efficiency in sectors like manufacturing and marine propulsion. This technology offers compact and economically viable alternatives for various applications, potentially lowering costs and making advanced technologies more accessible to a broader audience.

- Automotive, large vehicles, electric vehicles

- Aerospace, eVTOL

- Marine propulsion

- Renewable energy, viz., wind power, tidal power

- Energy storage and conversion

- Manufacturing, industrial machinery

- In-wheel drives, low-speed high-torque motoring, low-speed high-torque generating, continuously variable transmission (CVT)

Geography of IP

Type of IP

202221050099

496175