Fly ash is nothing but a pozzolanic material formed from thermal power plants during combustion of coals all over the world using crushed coal to generate electricity, which also results in approximately 1 MT (million tons) of annual production of the by-product fly ash that cannot be assimilated to the geo-environment while being disposed and becomes a major threat for environment pollution and land scarcity. Fly ash in bulk quantity has usually been used extensively for the construction of embankments in highways and railways. Removal of fly ash is the foremost concern in various countries where the majority of electrical energy is formed through thermal power plants in an environmentally friendly way. Consumption and removal of fly ash have been an emerging issue for several years in the joint venture of the Ministry of Environment and Forests and the Ministry of Power in India. Fly ash is used as a filling material for a combination of soil and admixtures in ground improvement and roads. Polyethylene terephthalate is commonly used to make disposable plastic bottles for water, juice, and soft drinks. These plastic bottles contribute nearly 50 % of the total plastic consumed in India, and as a whole it may be 18.9 MT in 2015. Almost 600 billion plastic bottles are discarded around the globe annually after a single serving, and only 47 % of the total is collected through different channels. It is a major concern to dispose of these non-biodegradable bottles, but in a country like India, approximately 75 % of discarded PET bottles are collected by various agencies, which is more than the worldwide average. Most of the waste plastic bottles collected from different sources finally arrive at an incinerator facility or landfill and some go to a recycling or down cycling facility for further processing. Disposable plastics contribute a great deal to plastic contamination. The rate of plastic effluence in the deserts and oceans is increasing rapidly. Recycling of plastic is not an ecological solution to the crisis because it is not an economical process; reuse of plastics is more favorable.

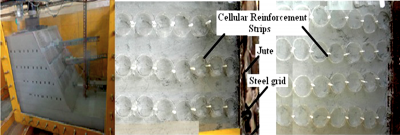

Our lab is also working in the following areas: Numerical analysis of expanded polystyrene geofoam fill railway embankment on soft ground; Proposed tests for geofoam; Multi-tiered fly ash wall reinforced with waste plastic bottle geocell; Numerical analyses on cellular mattress-reinforced fly ash beds overlying soft clay; Expanded polystyrene (EPS) geofoam embankments on soft soils; LSS model for designing of landfill; Numerical analysis on designed mixes using GGBS and sodium bentonite as a highway construction material; Numerical evaluation of expanded polystyrene (EPS) geofoam creep; End bearing encased stone columns and finite element modeling of floating encased stone columns in soft clay; Design of 300 m high artificial mountain using geosynthetics; Closure of near surface disposal facility for low level radioactive waste; etc.

Prof. J N Mandal