A simple, low-cost method turns ordinary pins and plastic into tiny, painless skin needles that deliver medicine without the pain of shots. Using a reusable rubber mold and biodegradable materials, these microneedle patches can be made in a standard lab and have been shown to pierce pig skin safely and release drugs over time.

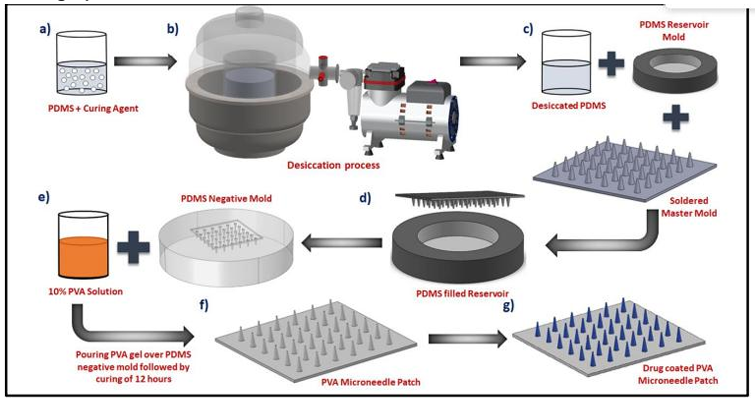

Figure 1. Graphical illustration of the drug coated PVA microneedles patch fabrication (a) PDMS and curing agent was taken in 10:1 ratio, (b) Vacuum pump was used for desiccation to remove air bubbles from the solution, (c) Desiccated PDMS solution, (d) Master mold was placed over PDMS reservoir to prepare negative mold for microneedle fabrication, (e) 10% PVA solution was poured onto the PDMS negative mold and cured for 12 hours at 45°C in hot oven, (f) Fabricated microneedle patch, (g) Drug was coated onto the microneedle patch.

Many people need to take medicine using injections, which can be painful and scary. Traditional needles can also cause waste, infections, and require trained professionals to use them. For people who need regular doses or vaccines, this becomes inconvenient and costly. There is a need for a painless, easy, and safe way to deliver medicine through the skin.

- Enables Simple Manufacturing: It uses common pins and a soldered board as a mold4 no clean rooms or expensive machines required.

- Offers a Reusable Mold System: The rubber (PDMS) mold can be cleaned and used over and over, cutting cost and waste.

- Delivers Painless Skin Piercing: Microneedles are tiny enough to slip through the outer skin layer without pain or bleeding.

- Works with Biodegradable Materials: Patch is made from FDA-approved polymers (like PVA) that dissolve or break down safely in the body.

- Supports Rapid Production: Entire patch can be fabricated and be ready for use in about 24 hours.

In the lab, head-pins are soldered into a 6×6 array on a small board to form a “master mold.” A rubber mix (PDMS) is poured over this, cured, then peeled away to leave tiny cavities. A water-based polymer solution fills the cavities, is dried overnight, and peels off as a microneedle patch. The prototype needles measure about 700 µm long with a 50 µm tip.

The technology has been successfully developed and tested in a laboratory setting. The microneedles were created using affordable materials and have been tested on pig skin, which is similar to human skin. Tests showed that the needles can pierce the skin safely and deliver medicine effectively. The product has also been proven to be safe for cells and durable under pressure.

4

By making injections painless and portable, this technology can improve vaccination rates, especially in rural and low-resource areas. It reduces medical waste and infection risk, lowering healthcare costs and environmental impact. Patients gain freedom from fear of needles and frequent clinic visits, leading to better treatment adherence and overall public health.

- Healthcare and medical devices

- Drug and vaccine delivery

- Public health programs

- Home-use medical products

- Pharmaceutical and biotech industries

Geography of IP

Type of IP

201921021470

553240