The invention discloses a method for fabricating a porous elastomer film by incorporating a leavening agent, such as a yeast solution, into an elastomer-curing agent mixture in a defined ratio. The composite is then subjected to a water bath-based curing process for a predetermined time, facilitating gradual heating and gas release to achieve a uniformly porous structure. The resulting elastomer film exhibits stretchability, controlled mechanical properties, and is suitable as a dielectric medium in capacitive sensors. The process is simple, cost-effective, and compatible with scalable, biocompatible applications.

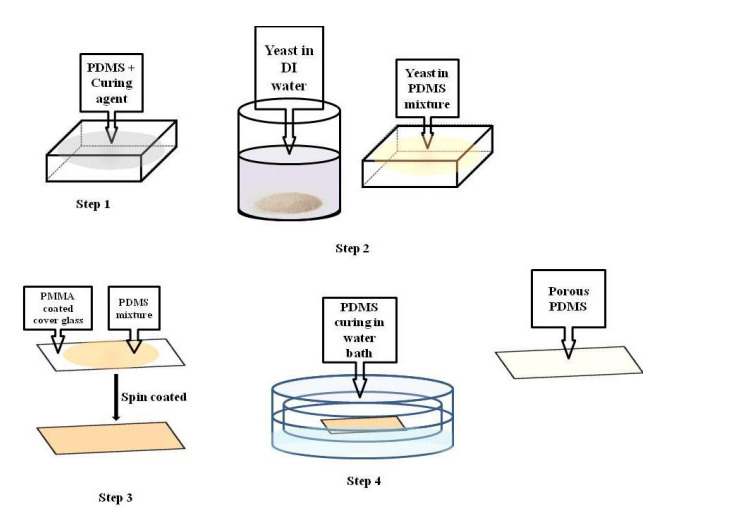

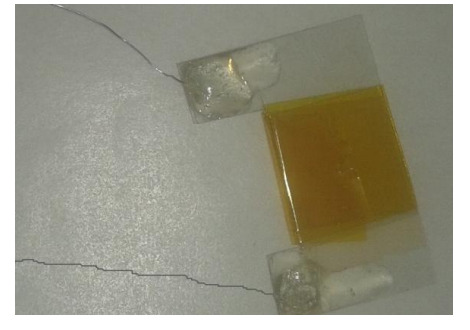

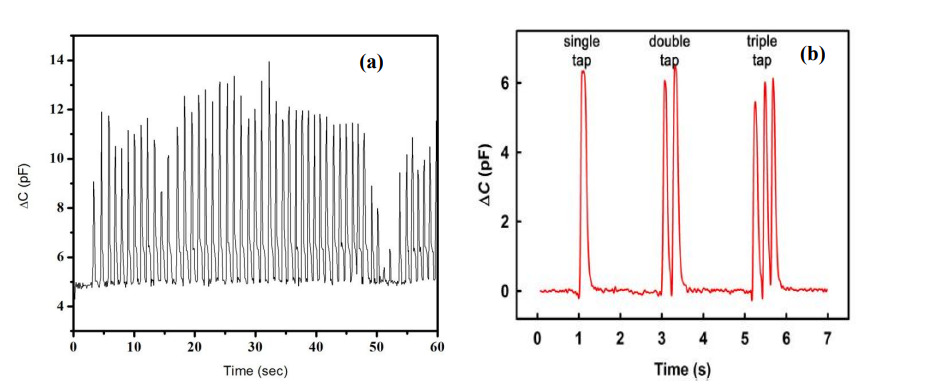

Figure (1) Schematic of experiment for this invention; (2) Pressure sensing device illustrating the proposed porous PDMS film as dielectric medium in the parallel plate capacitor; (3a) Change in capacitance of the parallel plate capacitor pressure sensor device, (3b) Reported change in capacitance of a similar configuration using porogen mediated porous PDMS. The change in capacitance with applied strokes of pressure with real time variation showing minimum response time giving ∆C/Co ~ 1.6 which is double of that reported in fig. (3b).

Existing fabrication methods for porous elastomer films are complex, time-consuming, and lack scalability. They often fail to achieve the required stretchability, uniform porosity, and mechanical robustness needed for flexible electronics and biomedical applications. Elastomers in their raw form are unsuitable for such use without morphological modification. A simple, cost-effective, and scalable method is needed to produce porous elastomer films with consistent mechanical and dielectric properties.

- Bio-Organism (Yeast) Based Leavening Approach: The invention uses a yeast-based leavening agent that releases gas during curing. This enables pore formation in the elastomer film without synthetic porogens.

- Simplified One-Step Fabrication: The process combines mixing, coating, and curing in a single workflow. It eliminates the need for complex equipment or multistep procedures.

- Spin-Coating Enabled Thin Film Deposition: A spin-coating step is included before curing to form uniform thin films. This ensures even surface distribution and film thickness control.

- PDMS Base with 10:1 Elastomer to Curing Agent Ratio: The elastomer mixture consists of PDMS and curing agent in a 10:1 ratio. This ensures consistent mechanical properties and reliable film formation.

- Tailorable Mechanical Properties via Yeast Concentration: Mechanical characteristics like Young’s modulus can be tuned by yeast amount. This tunability allows application-specific elasticity and stretchability.

- Compatible with Large-Area Flexible Electronics: The film fabrication method supports uniform coating over large surfaces. This makes it ideal for conformal and stretchable electronic platforms.

- Homogeneous Pore Distribution through Gradual Thermal Curing: The curing is performed in a water bath to allow slow gas release. This results in uniformly distributed pores and stable porous morphology.

A working prototype of the porous elastomer film was developed using PDMS (Polydimethylsiloxane) and a yeast-based leavening agent. The PDMS and curing agent were mixed in a 10:1 ratio. Separately, 0.7 grams of yeast was dissolved in 3 mL of deionized water, sonicated to form an emulsion, and then mixed into the PDMS blend. The mixture was deposited on a PMMA-coated glass substrate and spin-coated to form a uniform thin layer. It was then cured in a water bath through gradual heating for 2.5 hours, followed by air drying at room temperature for 1 hour. This curing method allowed for slow gas release, forming a homogeneous porous morphology.

The resulting film was approximately 500 μm thick and exhibited mechanical stretchability up to ~100% strain. The porous PDMS film was integrated as a dielectric layer between two ITO-coated PET sheets to create a parallel plate capacitive pressure sensor. The device demonstrated a significant and repeatable capacitance change (ΔC/C₀ ≈ 1.6) under applied pressure, confirming its functionality and sensitivity.

A functional prototype of the porous PDMS film has been fabricated and tested. The film shows uniform porosity, good stretchability, and has been successfully integrated into a capacitive pressure sensor, demonstrating high sensitivity and repeatable performance.

4

The technology enables low-cost, eco-friendly, and biocompatible fabrication of porous elastomer films using minimal ingredients. Its stretchable and flexible nature supports applications in biomedical sensing, wearable electronics, and human-interactive devices, eliminating the need for complex or hazardous fabrication processes. This approach promotes sustainable development and enhances accessibility to advanced electronic materials for healthcare and consumer use.

- Biomedical and Diagnostic Sensing: The porous elastomer film can be used as a sensitive dielectric layer in pressure sensors for real-time biomedical monitoring and diagnostic devices.

- Robotics and Prosthetics: The film’s stretchability and skin-like texture enable its use in electronic skin and tactile sensors for robotic and prosthetic systems.

- Consumer Wearables: Its flexibility and biocompatibility make it ideal for integration into wearable health and fitness monitoring devices.

- Automotive Interiors: The pressure-sensitive nature of the film allows its application in smart seat sensors and interactive control surfaces in vehicles.

- Environmental Monitoring: The sensor's ability to detect pressure variations enables use in ambient condition monitoring and responsive surface systems.

- Advanced Materials and Manufacturing: The fabrication method offers a scalable, low-cost approach to produce porous, stretchable films for flexible electronic components.

Geography of IP

Type of IP

201621035580

378970