The invention discloses a highly elastic polymer substrate made from a PDMS-b-PEO copolymer blend with benzophenone photoinitiator, providing both high stretchability and mechanical gradient capability. The substrate achieves over 300% elongation at break and enables UV-induced modulus patterning, making it ideal for stretchable electronics. The method is scalable, uses commercially available materials, and requires no intermediate modulus-matching layers.

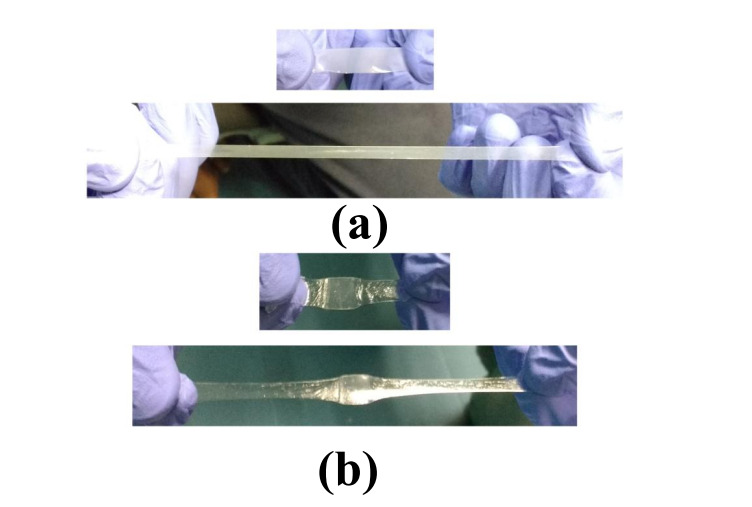

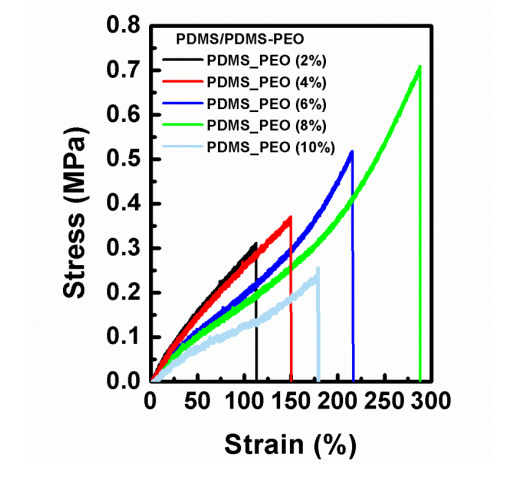

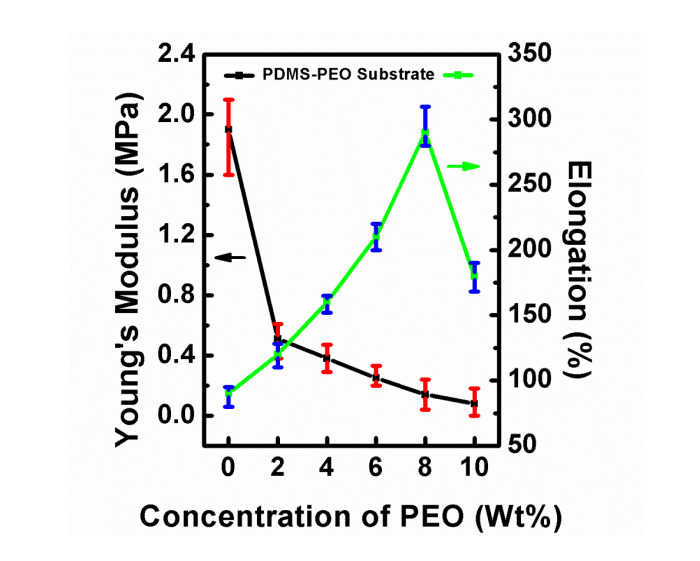

Figure (1) Demonstrates the highly stretchable (1a) and high mechanical gradient stretchable (exposed and unexposed), (1b) substrates with 4 wt% of PDMS-b-PEO in PDMS: Benzophenone mixture; (2) Demonstrates the change in elongation at break with varying concentration of PDMS-b-PEO; (3) Demonstrates the variation of modulus and elongation break with change in PDMS-b-PEO concentration.

Traditional stretchable electronics rely on rigid islands embedded in elastic matrices, which often suffer from delamination and mechanical failure due to strain concentration at the interface. Current materials also lack the required stretchability and mechanical gradient needed to accommodate large deformations without performance loss. There is a need for a substrate that is highly stretchable, photo patternable, and capable of maintaining mechanical integrity under strain.

- Mechanically Gradient Substrate: The substrate incorporates a gradient in mechanical modulus using UV-sensitive benzophenone, which enables strain relaxation at the interface between soft and rigid regions, reducing stress concentration.

- High Stretchability: The incorporation of PDMS-b-PEO significantly enhances the elongation at break to approximately 280%–300%, greatly exceeding the performance of conventional elastic substrates.

- Photopatternable Architecture: By using patterned UV exposure, the substrate allows localized crosslinking variations, enabling spatial tuning of stiffness for precise placement of electronic components.

- Single-Material Integration: The system achieves mechanical gradient functionality without requiring additional interfacial layers or blending of different base polymers, simplifying the fabrication process.

- Process Simplicity: The substrate is prepared using Sylgard 184 and standard additives through straightforward mixing, molding, UV exposure (where required), and thermal curing steps.

Two functional prototypes were developed to demonstrate the capabilities of the substrate. The first prototype involved a highly stretchable substrate composed of Sylgard 184 blended with 8 wt% PDMS-b-PEO, which was thermally cured at 80°C. This formulation exhibited exceptional elongation at break and mechanical stability. The second prototype was designed for photopatterning applications and was prepared using a blend of Sylgard 184 with 4 wt% PDMS-b-PEO and 3 wt% benzophenone. This substrate was UV-exposed through a lithographic mask to create spatially defined modulus gradients, followed by thermal curing. Both prototypes demonstrated enhanced stretchability and mechanical tunability. Rigid SU-8 islands were successfully bonded onto the photopatterned substrate using screen-printed silicone adhesive, confirming its suitability for integration in stretchable electronic systems.

The substrate has been fabricated and successfully tested at the laboratory scale. The mechanical gradient has been demonstrated using photopatterning with benzophenone, and elongation at break exceeds 300% with optimized PDMS-b-PEO composition. Device fabrication using SU-8 islands on patterned regions has been validated using standard lithography and adhesive bonding techniques.

7

This substrate enables the next generation of stretchable and wearable electronics for healthcare, robotics, and human–machine interfaces. Its high stretchability and mechanical adaptability reduce device failure, enhance comfort, and extend application possibilities in flexible electronic systems.

- Flexible and Stretchable Medical Electronics: Enables integration of skin-conformal electronics for real-time health monitoring

- Artificial Skin and E-Textiles: Supports development of e-skin systems mimicking skin-like stretchability and compliance

- Bio-Integrated Electronics and Implantables: Facilitates long-term implantation with reduced mechanical mismatch at tissue interfaces

- Soft Robotic Systems and Sensors: Allows localized stiffness control for sensing and actuation in soft robotics

- Flexible Displays and Optoelectronics: Provides mechanically stable support for stretchable or curved optoelectronic devices

- Wearable Motion Capture and Health Monitoring: Adapts to body motion for continuous tracking of movement and physiological signals

Geography of IP

Type of IP

201621011548

375146