It is well known that the traditional paradigm of the materials science tetrahedron depicts the inter-dependent relationship among the structure, properties, processing, and performance of a material. The demand for high performance structural materials for real world applications has undoubtedly driven scientific efforts for the past few decades due to stringent regulations on efficiency and emissions. One of the fundamental routes of achieving this goal is through microstructural engineering which is used to control parameters such as grain size, texture, grain boundary nature and residual stress which are critical for material performance. In view of this, my research group focuses majorly on synthesis / processing, characterisation of microstructural stability, and evaluation of mechanical properties of various metallic alloys (both ferrous and non-ferrous metals and alloys) and metal matrix / metal particles reinforced composites (Ni-Al, Ni-Ti, etc.).

One of the major research activities in our group involves use of pulsed electrodeposition method as one of the routes to engineer the microstructure where the material is ‘grown’ from the salt solution of the metals along with suitable additives by passing electricity. This enables precise control of grain size, morphology and introduction of second phase reinforcements into the parent material to fabricate pure metals and their composites.

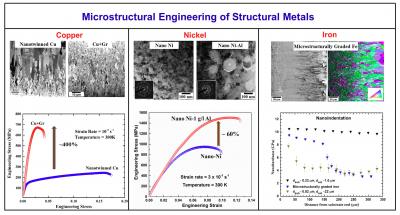

Our team has demonstrated the electrodeposition of copper containing high density of nano-twins which are known to enable mechanical strengthening as well as high thermal stability. With addition of graphene as reinforcement in copper, the yield strength improved from ~140 MPa to ~700 MPa corresponding to 400% improvement over pure copper. Our team is also involved in electro-deposition of nano-crystalline nickel and reinforcements with various metallic nanoparticles. Nano-crystalline nickel with additions of nano-aluminium particles showed 60% increment in flow stresses (upto~1500 MPa) with no loss in ductility. Our lab also works on fabrication of microstructurally graded materials which show varying mechanical properties from one side of the material to the other. We have recently demonstrated microstructurally graded pure iron having nano-crystalline grains with high hardness (~10 GPa) on one side and coarse soft grains (~4 GPa) on the other side with precise control on the hardness gradient through control of the electrodeposition parameters.

Furthermore, work is in progress to develop new ferrous alloys with improved mechanical properties and oxidation and corrosion resistance. We are also studying various plastic deformation mechanisms such as twinning / detwinning activities in low stacking fault energy materials such as Cu-Al alloys and Co-Ni-Cr-Mo alloys, and the deformation behaviour of the light alloys such as Al-Cu-Li, Al-Mg-Sc and beta Ti alloys at room temperature and elevated temperatures. We have been attempting to produce novel laminated (or multilayered) metallic alloys and claddings by electrodeposition and roll bonding processes.

Prof. MJNV Prasad