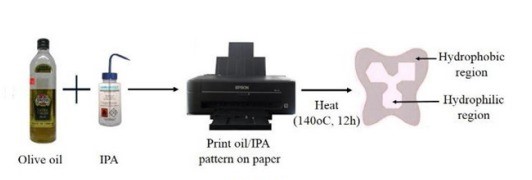

The present invention provides an environment-friendly and economical method for increasing the hydrophobicity of the paper or paper-like materials. In an aspect, the invention provides a non-toxic, biodegradable cellulose reactive sizing agent that when printed on the paper or paper-like material followed by heating the paper or paper-like material increases its hydrophobicity; wherein the cellulose reactive sizing agent comprises a vegetable oil suspended in a carrier solvent. In yet another aspect, the invention provides a device for printing cellulose reactive sizing agent on the paper or paper-like material. The invention also provides a paperfluidic device and a method for manufacturing the same.

Despite various techniques to enhance the hydrophobicity of paper or to print hydrophobic barriers for paper-based microfluidic channels, current methods face drawbacks like high cost, toxicity, brittleness, and complex processing. Physical methods (e.g., SU-8 photolithography, inkjet/flexographic printing, wax printing) often produce rigid, damage-prone barriers or use regulated materials. Chemical agents like AKD and ASA, though effective, are expensive, toxic, and require high dosages. Thus, there is a need for a simple, economical, non-toxic, and durable method to enhance paper hydrophobicity without affecting its strength or printability.

- Chemical hydrophobic modification using cellulose-reactive sizing agents: Vegetable oils in carrier solvents chemically bond to cellulose in paper via transesterification, enhancing water repellency without blocking pores or altering paper structure.

- Affordable modified inkjet printing platform: A low-cost inkjet printer with refillable cartridges prints oil-based inks at precise locations, enabling small reagent volumes and making the technology accessible for low-resource environments.

- Optimized ink formulation for reliable inkjet printing: A balanced ink with 10% oil in isopropanol meets surface tension and viscosity requirements for inkjet printing, ensuring consistent droplet formation and protecting printer components from blockage.

- Thermal curing creates permanent hydrophobic patterns: Heating the printed paper at 100–150°C for ~ 8 hours chemically bonds oils to cellulose, resulting in durable, long-lasting water-repellent regions.

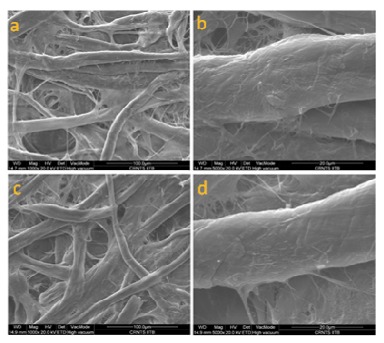

- Chemical, not physical, patterning validated by SEM and FTIR: Imaging confirms no pore blockage. FTIR identifies ester carbonyl groups, proving chemical modification of cellulose as the mechanism for increased hydrophobicity.

- Wide compatibility with solvents, oils, and paper types: It supports various combinations of vegetable oils and solvents, and works on multiple paper substrates such as chromatography, filter, and tissue papers for diverse applications.

- Scalable, eco-friendly, and versatile technology: It uses food-grade materials and standard office printers, offering an affordable, sustainable solution for microfluidics and analytical paper-based devices.

This invention uses a modified low-cost inkjet printer (under USD 45) equipped with refillable cartridges loaded with a cellulose-reactive sizing agent—vegetable oil (e.g., olive oil) suspended in isopropanol. The printer deposits the oil-based ink precisely onto chromatography paper (20 cm x 20 cm), creating hydrophobic patterns through a single print cycle. After printing, the paper is thermally cured at 100–150°C for ~8 hours to chemically bond the oil to the cellulose via transesterification. The printed paper exhibits durable hydrophobicity with contact angles between 117°C and 130°C. The chemical modification is confirmed through FTIR, while SEM analysis confirms no blockage of paper pores. The patterned paper maintains its properties for several years under ambient conditions.

No further development has been done since publication of the related manuscript in 2015.

4

This technology democratizes access to hydrophobic paper treatments using low-cost, eco-friendly materials and modified office printers, making it accessible to schools, small labs, and resource-limited areas. Its sustainable approach reduces chemical waste and enables affordable, durable paper-based diagnostic devices, improving healthcare in underserved communities globally while supporting green innovation with broad societal benefits.

- Paper-based microfluidics

- Paper-based senosrs

- Frugal diagnostics

- Medical diagnostics

- Environmental monitoring

- Food safety testing

- Low-cost manufacturing

Geography of IP

Type of IP

1652/MUM/2014

390540