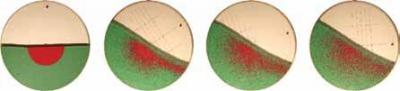

Powders, or granular materials more generally, are widely handled and processed in different industries (e.g., pharmaceutical, chemical, ceramic, steel, food and agriculture). The flow of granular materials is quite different from fluids and in the case of mixtures, the particles have a tendency to spontaneously separate out (segregate). We have been working on developing an understanding the rheology and mixing/segregation of granular materials using experiments, continuum models and particle level simulations. Simple prototype systems such as rotating cylinders and chutes have been studied to obtain general results. Specifically, mathematical models have been developed to predict flow, mixing and segregation in different systems and validated by experimental or simulation results.Based on the results, a novel method for reducing segregation in rotary kilns has been devised, which has been patented. The body of results provide new insights for designing systems for handling granular materials, including rotary kilns, chutes, granulators, blast furnaces and mills, which are used in industry.

Prof. D V Khakhar