This invention achieves a polymer pressure sensor with ultra-sensitivity to measure ultra-low pressure lower than 100Pa, which is cost-effective, easy to fabricate without the need of sophisticated instruments or dust-proof manufacturing facilities. Further, the embodiments herein achieve the polymer pressure sensor which is fabricated by printing a diaphragm based piezo resistor on a self-adhesive flexible substrate. The embodiments herein achieve the polymer pressure sensor which is flexible and durable. Additionally, the embodiments herein achieve a fabrication method for the polymer pressure sensor, which is easy, cost-effective, has minimal number of steps and is scalable. Also, embodiments herein achieve the fabrication method for the polymer pressure sensor which uses dry nanomaterial/nanoparticle powder for fabrication of the polymer pressure sensor without the requirement of sophisticated instruments and preparation of conductive inks.

Current pressure sensors, particularly piezo-resistive types, often require sophisticated equipment and dust-proof facilities for their fabrication, making them expensive and time-consuming to produce. Additionally, existing flexible pressure sensors can be costly and inefficient, requiring complex fabrication processes such as thermal evaporation or sputtering. There is a need for a cost-effective, simple, and scalable method to produce flexible piezo-resistive polymer pressure sensors with high sensitivity, especially for applications requiring ultra-low-pressure detection (below 100 Pa).

- Self-Adhesive Flexible Substrate and Simple Fabrication: The sensor uses a polymer mixture (silicone gel and PDMS 184) to create a self-adhesive flexible substrate, acting as the diaphragm, and employs a simple fabrication process involving spin coating and dry nanomaterial deposition (e.g., carbon black), eliminating the need for complex conductive inks or sophisticated instruments.

- Ultra-Low-Pressure Sensitivity: The sensor is designed to detect pressures lower than 100 Pa, providing high sensitivity suitable for precise measurements in sensitive environments, such as in wearable devices and medical diagnostics.

- Cost-Effective, Scalable, and Versatile: The fabrication method is cost-effective, scalable, and does not require dust-proof environments, making it ideal for mass production and enabling broad applicability in industrial, environmental, and consumer electronics applications.

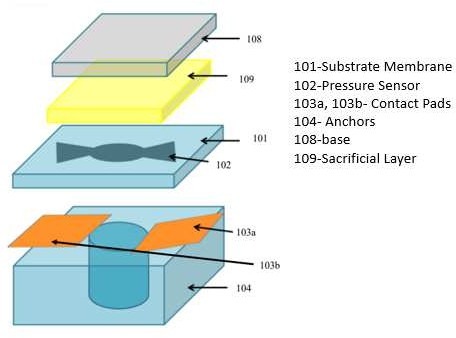

The prototype consists of a self-adhesive flexible substrate made from a polymer mixture of silicone gel and PDMS 184 (in a 10:1 to 30:1 ratio), serving as the diaphragm. A piezo-resistor is printed on the membrane using dry nanomaterial powder (such as carbon black or MWCNT) in a piezo-resistive circuit design. The sensor includes two PDMS 184 anchors with cavities to support the diaphragm and maintain the sensor’s stability. Copper strips are used as contact pads, providing electrical connectivity to the piezo-resistor. The entire sensor is housed in transparent acrylic lids, with cavities allowing air passage to the diaphragm for pressure sensing.

The technology is in pre-clinical research, proof of concept stage.

3

The societal impact of this technology is significant across multiple domains. The cost-effective and scalable manufacturing method enables mass production of flexible pressure sensors, reducing costs and making the technology accessible for various applications. Its ultra-sensitivity makes it ideal for wearable health monitoring devices and the ability to detect low pressures supports environmental protection by monitoring air pressure and fluid flow. In medical devices, this sensor improves diagnostic accuracy, especially in respiratory and cardiovascular healthcare.

- Healthcare and Medical Devices: Wearable devices, respiratory monitoring, prosthetics, and medical diagnostics

- Environmental Monitoring: Pressure sensing for air quality and fluid flow in environmental sensors

- Industrial Design: Use in flexible electronics and sensitive pressure systems

- Automotive and Aerospace: Pressure sensors for vehicle systems and aerospace applications requiring lightweight and flexible materials

- Consumer Electronics: Integration into touch screen devices and wearables for pressure-sensitive applications

- Robotics: Pressure sensing in robotic systems requiring tactile feedback

Geography of IP

Type of IP

202221048220

439404