The present invention discloses a method of predicting failure in terms of crack direction under different modes of deformation of planar anisotropic sheet metal. The method comprises performing a tension test on a specimen in three different orientations and calculating Lankford coefficients for the specimen from an r-bar test in those three orientations. After calculating the Lankford coefficients, failure or deformation in terms of crack direction is determined.

Accurate prediction of crack propagation direction in planar anisotropic sheet metals under biaxial loading conditions remains a significant challenge due to the absence of a distinct principal stress direction. Existing methods primarily address uniaxial or plane strain conditions and fall short in providing reliable predictions for complex sheet forming operations. This often results in unanticipated material failure, increased production costs, and inefficient design iterations in industries reliant on metal forming.

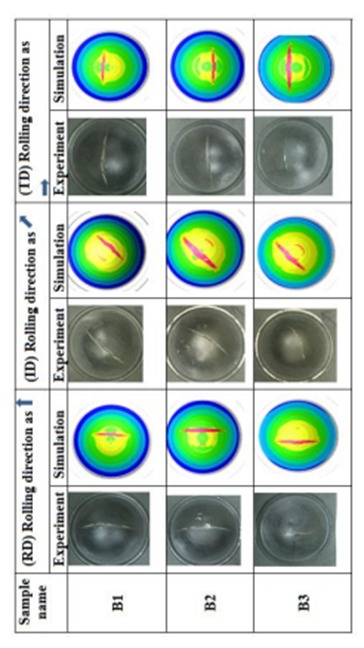

- Predictive Methodology: A novel method that combines tension testing and R-bar testing in three orientations (RD, ID, TD) to calculate Lankford coefficients (R-values).

- Biaxial Crack Prediction: It enables directional crack prediction under biaxial deformation, a long-standing challenge in sheet metal forming.

- Reduced Experimental Dependency: Avoids reliance on costly and time-consuming full-scale Limiting Dome Height (LDH) tests for initial failure assessment.

- Simulation Validation: Method has been validated via Finite Element Analysis (FEA) simulations in PamStamp-2G and experimental LDH tests—ensuring high accuracy and industrial relevance.

- Improved Formability: It supports material and process design by identifying the most favorable orientations for forming, thus minimizing failure risk and optimizing sheet utilization.

NA

The repeatability of the invention has been demonstrated using LDH experiments on a wrought aluminum alloy under an industrial-scale forming press in a laboratory environment. These results should be readily transferable to an actual industrial forming press.

4

The proposed technology offers societal benefits by improving the reliability and efficiency of sheet metal forming. Accurate prediction of crack direction under biaxial loading reduces material wastage, lowers costs, and minimizes environmental impact. It also enhances product safety in critical sectors like automotive and aerospace, while empowering engineers with data-driven insights to drive sustainable and high-performance manufacturing across industries.

- Automotive industry

- Aerospace industry

- Shipbuilding

- Metal forming and die design

Geography of IP

Type of IP

3589/MUM/2015

455043