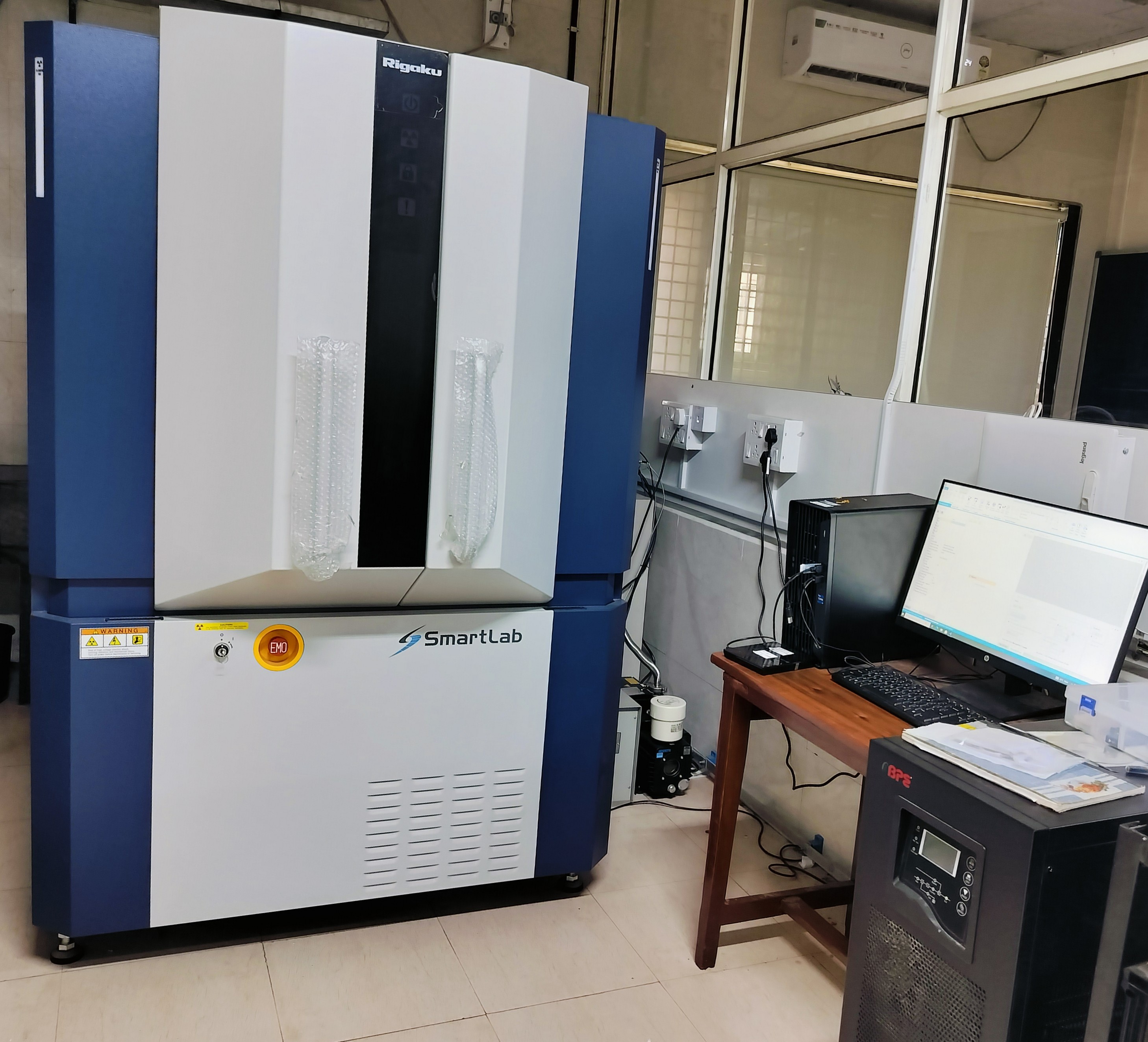

X-ray diffractometer facility at Chemical Engineering

Rigaku SmartlabSE

The present model is also equipped with two stages:

- High-temperature stage - The High-Temperature Attachment (HT-XRD) can operate from ambient temperature up to 1500°C in air, up to 1450°C in a vacuum, and up to 1300°C in an inert gas.

- (OPERATIONAL)

- Electrochemical stage - An electrochemical stage with electrical feedthrough through the X-ray chamber and potentiostat for in-situ analysis for aqueous electrochemistry applications only. (NOT YET OPERATIONAL).

- For powdered samples: Bragg -Brentano optics (Conventional divergent beam)

- High-temperature stage - Sample heating stages capable of heating from ambient to 1500C in inert or vacuum with suitable software to collect XRD scans at intermittent temperature. (OPERATIONAL)

- Electrochemical stage - An electrochemical stage with electrical feedthrough through the X-ray chamber and potentiostat for in-situ analysis for aqueous electrochemistry applications only. (NOT YET OPERATIONAL)

The X-Ray Diffraction System SmartLab SE includes the SmartLab SE Goniometer with a scanning radius of 300 mm (diameter 600 mm) and a 3 kW sealed ceramic Cu X-ray tube. The maximum tube voltage is 60 kV, and the maximum tube current is 60 mA. The DTex 250 sensor is a semiconductor strip sensor with an active area of 384 mm² (19.2 x 20 mm). The system features an automatic slit exchanger with alignment and control, along with automatic systematic error correction. The solar slits are available in 2.5 degrees and 5 degrees for the incident and diffracted beams, respectively, and are easily interchangeable. Additionally, the system includes a Ni filter. The minimum step angle is 0.0001 degrees, and the scanning angle range is -10 to +160 degrees in 2 theta.

The enclosed cabinet has doors designed for easy access and adheres to regulations for X-ray, electrical, and mechanical safety. Additionally, the system includes Data Collector software, which provides functionalities such as data acquisition in an appropriate format, tools for determining measurement strategies, configuration and measurement management, automatic processing, and data conversion and viewing capabilities for X-ray diffraction systems.

The High-Temperature Attachment (HT-XRD) can operate from ambient temperature up to 1500°C in air, up to 1450°C in a vacuum, and up to 1300°C in an inert gas. It is equipped with a JIS Type (2) thermocouple. The sample size is 13.5 x 25 x 0.5 mm.

- Identification of unknown crystalline materials

- Characterization of crystalline materials

- Determination of crystal structures

Room 125 A/101, Ground floor,

Department of Chemical Engineering,

I.I.T. Bombay, Powai, Mumbai - 400076

Contact No: 022 2576 4234

- Mr. Akash Shinde: sakash@iitb.ac.in

- Ms. Prachi Janjani: 22d2025@iitb.ac.in