Understanding Boron's Microscopic Behaviour for Next-Generation Superalloys

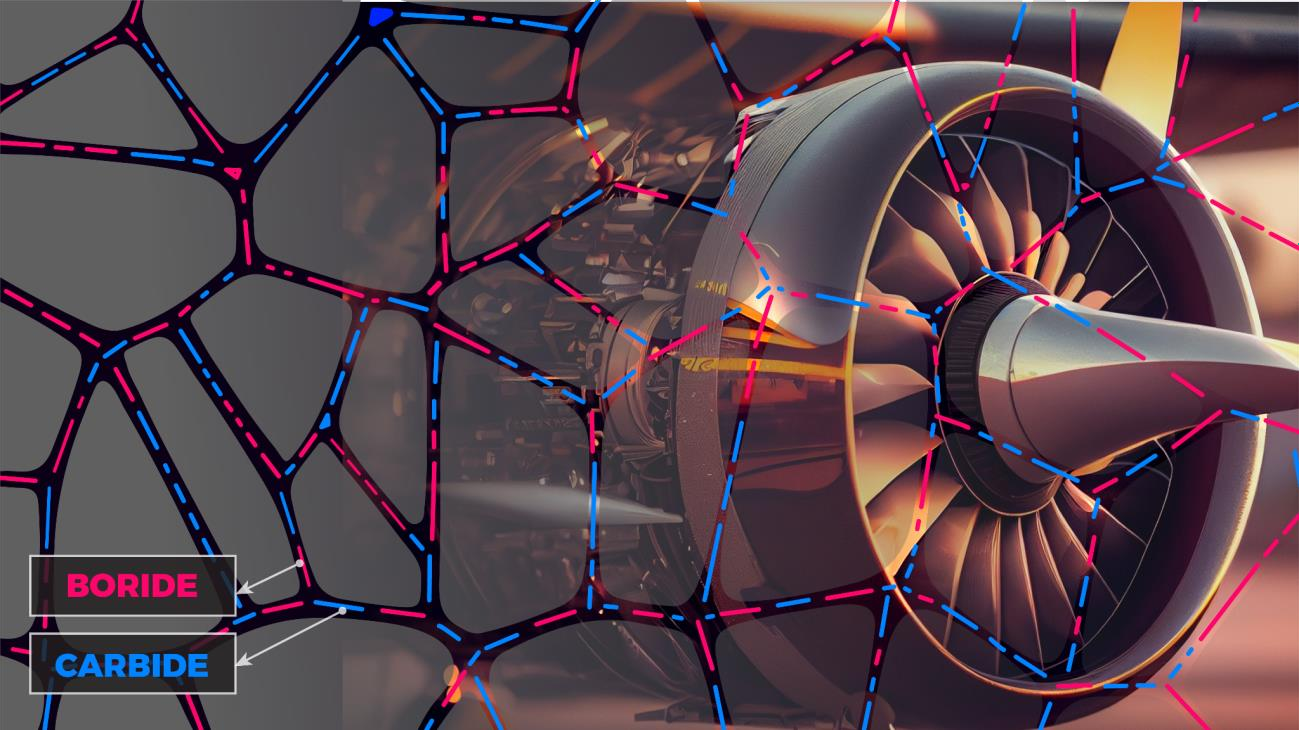

Researchers provide new insights on borides in superalloys contributing to enhanced high-temperature performance.

Superalloys are alloys that are designed to withstand incredibly high temperatures and pressures for extended periods, serving crucial roles in the aerospace industry. Researchers from the Indian Institute of Technology Bombay (IIT Bombay) have made a breakthrough in understanding the role of boron, a key element, in strengthening nickel-based superalloys often used in high-performance parts for jet engines. The effectiveness of the superalloys mostly depends on their chemical content and microstructure stability. That's where boron comes in—it has been identified as effective in extending the lifespan of the components of the jet engine.

To offer some background, metals and alloys have a polycrystalline structure which means that they are made up of small 'grains'. The interfaces between these grains are called 'grain boundaries'. It is along these grain boundaries that boron is at work, but exactly how it improves the alloy’s performance has been a topic of debate among researchers.

“At high temperatures, grain boundaries are not preferred as they can act as crack nucleation sites and lead to catastrophic failure. Therefore, understanding the role of boron as a grain boundary strengthener is essential for all industrial applications where superalloys are used,” explains Richa Gupta, lead author of this study from the Department of Metallurgical Engineering and Materials Science, IIT Bombay.

In an earlier study, Richa Gupta, Prof Prita Pant, Prof. M.J.N.V Prasad from IIT Bombay and Prof. K.C.H. Kumar from IIT Madras had shown that borides, which are compounds of boron with a metal, appear as nearly spherical, nano-sized particles along these grain boundaries. They appeared to improve the mechanical performance of the alloy by changing the microchemistry along these boundaries. The researchers noted that these borides prevent the clumping of carbides at the grain boundaries, potentially explaining the improved performance. Thus, the research answered some vital questions on the role of boron in superalloys.

Interestingly, these researchers discovered a gradient in composition within these nano borides. The boride particles showed a gradual change in their chemistry. High-resolution microscopy tools such as field emission gun scanning electron microscope (FEG-SEM) were used to analyse the alloy's microstructure and transmission electron microscope (TEM) was used for imaging in conjunction with energy dispersive spectroscopy (EDS) for elemental analysis.

In a more recent study, researchers have gained a better understanding of how high-temperature ageing treatments affect the structure and performance of a boron-modified nickel-based superalloy known as GTD444, which is developed by General Electric (GE). The focus of their research was on grain boundary precipitates – small particles that form along grain boundaries and significantly influence the life of a component at elevated temperatures.

The researchers carried out advanced high-resolution characterization, including atom probe tomography, to investigate how the small particles evolve when subjected to temperatures as high as 900 degrees Celsius to mimic the conditions on a jet engine's turbine blades and reported interesting results. They found that when the boron-modified GTD444 was aged at 900 ℃, the borides were stable for up to 80 hours. However, after this period, the researchers found that the borides transformed into carbides, which are another type of small particles. The two types of carbides they discovered were labelled as M23C6 and M6C. M6C contained chromium, tungsten, and molybdenum, and cobalt and nickel atoms at a 2:1 ratio, while M23C6 was a chromium-heavy carbide with small amounts of tungsten and molybdenum. Delving further into the process, the researchers found that the conversion of borides to carbides was related to the chromium content in the neighbourhood of the grain boundaries. The borides are stable until chromium content falls below around 8.6 particle percentage.

The research team noted that the transformation of borides to carbides resulted in a decrease in strength, but an increase in ductility – the ability of the material to stretch without breaking. This appears to suggest that the presence of discrete particles, whether borides or carbides, along the grain boundaries in the material, helps to prevent it from failing along the grain boundaries.

“Since the amount of boron added is very small, and it is a relatively light element, both qualitative and quantitative identification of boron is quite challenging. The role of boron could be studied using high-temperature in-situ deformation experiments in the electron microscope,” notes Richa Gupta. “Further, such a study could be carried out on samples with varying amounts of boron to identify all microstructural factors that contribute to grain boundary strengthening, such as segregation of elements, precipitates, and misorientation,” she adds.

“Understanding the formation and growth of borides in nickel superalloys is crucial for improving their resistance against deformation. Our research provides valuable insights into how borides develop and change over time, as well as their impact on the material's mechanical properties. This knowledge is crucial for optimising the microstructure and enhancing the alloys' ability to withstand high temperatures,” signs off Prof Prita Pant.

The research is particularly exciting news for industries like aviation and energy, where superalloys have widespread application, particularly in high-stress, high-temperature environments.