Polymer Processing Lab

- DSM XploreTM 5cm3 twin-screw extruder

- Haake Mini Jet pro

- Process 11 twin screw extruder

- Single screw extruder

DSM XploreTM 5cm3 twin-screw extruder

- Conical Twin Screw: Co-rotating

- Injection molding (DSM XploreTM 3,5 cm3 Laboratory Injection-Moulding)

- Recirculation facility

- Tensile/rectangular mold

Haake Mini Jet pro

- Injection molding

- Molds: Tensile (ISO/ASTM/Type 3), Disc, Rectangular

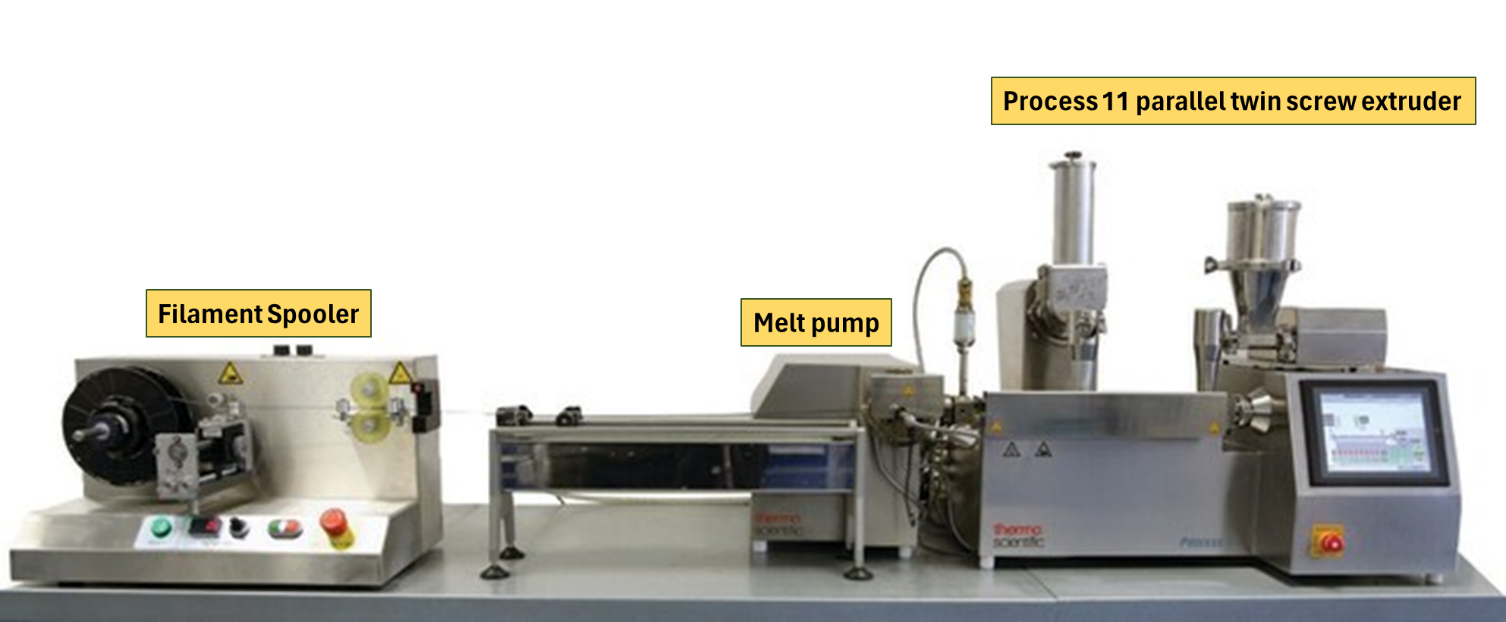

Process 11 parallel twin screw extruder

- Extruder: Parallel and Twin die

- Feeders: Gravimetric single/twin screw feeder

- Set of dies

- Melt pump

- Take-up spool and winder

Single Screw Extruder

- Single Screw

- Sheet die

- DSM XploreTM 5cm3 twin-screw extruder

The capacity of mixing a few grams of polymeric materials (up to 5g) during melt-mixing of polymer blends or making polymer nanocomposites. Extruded strand (diameter ~2mm)

- Haake Mini Jet pro

TThe HAAKE Mini Jet Pro system is designed as a piston injection molding system. Material consumption is reduced dramatically in comparison with conventional injection molding units due to:

- Reduced cylinder volume, resulting in a smaller quantity of required material

- Almost complete transportation of material into the mold, this giving minimal loss and waste

In addition, an injection pressure of up to 1100 bar can be realized, thus enabling the processing of highly viscous materials.

Design Features

- Simple loading of powders and pellets within the system cylinder

- Quick and easy removal of the heated cylinder for melt applications when connecting to the HAAKE Mini Lab or other extrusion systems

- Simple design for the exchange of molds without tools

Process 11 parallel twin screw extruder

Process 11 twin screw extruder is a machine for producing small batches or performing continuous production. The instrument is based on twin screw technology with parallel co-rotating screws and works as a standalone unit. This small-seized, high-tech tool is perfect for preparing samples for product trials and for micro-production of small batches.

Single screw extruder

- Polymer melt processing, including blends, addition of additives and fillers

- Preparation of samples using injection molding (variety of moulds are available)

- Formulation: Analyze the influence of types of additives, fillers, concentrations, polymer types, etc.

- Processing: Measure the impact of processing time and temperature.

- Performance: Predict the performance of the material before actual application

- Prof. Guruswamy Kumaraswamy

Polymer Engineering Lab, Department of Chemical Engineering, I.I.T. Bombay, Powai, Mumbai - 400076

Contact No:8080738499

Lab No: 022-2159 6162

- Ms. Vishakha Bansod

Prof. Guruswamy Kumaraswamy

Prof. Jayesh Bellare

Prof. D N Singh

Prof. D V Khakhar

Prof. Rohit Srivastava

Prof. Parag Bhargava