- TECHNICAL SPECIFICATIONS

- SPECIAL FEATURES

- WORKING PRINCIPLE

- CENTRAL FACILITY WORKSHOP PRESENTATION

- FAQ

- PUBLICATION USING DATA FROM FACILITY

- INSTRUCTION FOR SAMPLE PREPARATION

- INSTRUCTIONS FOR USERS

- INSTRUCTIONS FOR REGESTRATION

1.SM XploreTM 5cm3 twin-screw extruder

- Total capacity: 5 cm3

- Net. capacity: 4.5 cm3

- Screw length: 107.5 mm

- Maximum operating temperature 350oC. Heating time from 20oC to 240oC is 10 minD. Cooling time from 240oC to 80oC is 10 min.

DSM XploreTM 3,5 cm3 Laboratory Injection-Moulding Machine

- Barrel capacity: 3.45 cm3

- Mold area: 90 x 25 mm2

- Compressed-air cylinder (3-16 bar)

- Maximum operating temperature: 350oC Heating time from 20 to 240oC: 3 minutes.

2.Haake Mini Jet pro

- Total capacity: 2 to 5mL of material

- Max. injection pressure: 1100 bar

- Max. air pressure bar 10; filtered (50 µm), oil-free, dry compressed air

- Max. cylinder temperature: 450 °C

- Max. mold temperature: 250 °C

3. Process 11 parallel twin screw extruder

- Minimum required material: 50 g

- Process 11 Set of die Inserts: 0.5, 1.0, 1.5, 2.5 mm

- Barrel length: 40 L/D (440 mm)

- Ratio screw outer dia./ inner dia.: 1,72

- Temperature range: RT to 350 °C

- Maximum pressure: 100 bar (1450 psi)

- Screw Speed Range: 10 ... 1000 rpm

Process 11 melt pump

- Pump volume: 0.6 cm3/rev

- Pump speed: 0.1 - 60 rpm

- Volume stream: 0.036 - 1.8 l/h

- Max pressure: 500 bar

- Temperature: RT to 450 °C

- Die adapter to connect

Filament Spooler

- Coiling speed: 0.5 to 20 m/min

- Max. ø of round plastic material: 4.0 mm

Spool data

- Outer diameter/width: ø200 x 100 mm

- Hole for spool shaft min: 16 mm

- Spool core diameter 60 mm min. equal to the diameter of the peel-off rolls

4.Single screw extruder

- Recirculation

- Use pellet, powder, or melt samples

- Provides efficient sample preparation for mechanical and rheological testing

- Diameter monitor for the strand

- Sheet take-off setup

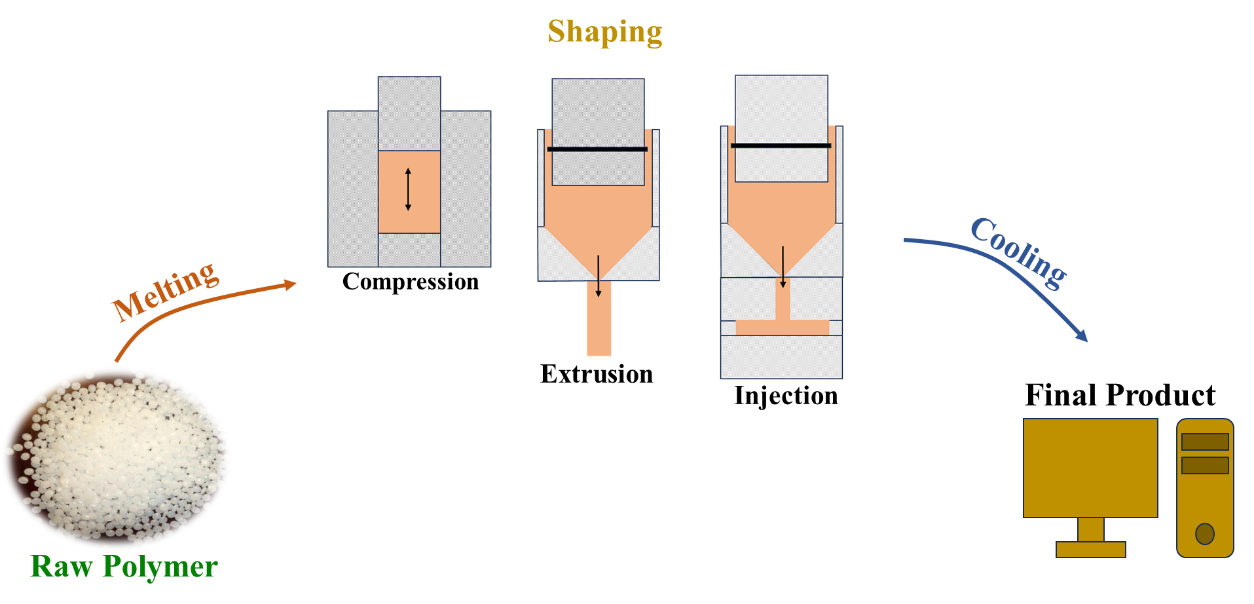

The majority of polymeric raw materials are available in granules, powder, or flakes form. The transformation from solid to flowable form is carried out by heating the material. Once the material is in a melted state, mold is used to shape the material, and the resulting shape is then fixed by cooling.

- Types of material we can use: Most thermoplastic materials, including blends, filled systems, etc.

- Maximum temperature range of machine: 450oC

- Size of material we can use: Typically pellets of 1-2mm size

- Material should be dry, and its melting temperature should be within 300 °C

- Required sample volume depends on the instrument type that will be used.

- Carry an extra 20 -30gm of your material.

We shall accept online registration only through the IRCC webpage. If you need to cancel your slot, send an email immediately with an explanation.

• Slots will be provided depending on availability. • Users must be present during the entire slot. • Material should be oven dried before usage. • User should be aware of the melting temperature and degradation temperature. • Material should be free from toxin material or any harmful gases. • Fillers that can stick to the barrel walls will not be accepted.

- User can register only through IRCC site.

- The date and time of slot will be informed to user by an email. If user cannot come, a mail should be immediately sent to mmimoulding [at] iitb [dot] ac [dot] into cancel his/her slot.