This invention introduces a new type of electric motor that combines two functions motor operation and gear speed control into a single, compact system. It removes the need for heavy magnets and reduces complex parts, making the motor easier to build, more energy-efficient, and cheaper. It’s designed for use in machines or vehicles that require high-speed performance without taking up too much space or using a lot of electricity.

Traditional electric motors that require gear systems often rely on separate parts and expensive materials like rare-earth magnets. These motors are bulky, expensive to build, and waste energy. Additionally, they are complicated to assemble and maintain. There is a growing demand for a more efficient, affordable, and compact motor that can offer both power and speed without these drawbacks.

- Compact Two-in-One Design: This product combines the motor and gear mechanism into a single unit, reducing the number of parts and saving space.

- Less Use of Rare Earth Magnets: This design reduces dependency on costly and limited rare-earth magnets, making the system more affordable and environmentally friendly.

- High Speed with Simpler Control: This feature uses a smart internal gear system that allows the motor to run at higher speeds without needing a complex external controller.

- Simplified Assembly: The motor is built with fewer moving parts and only two air gaps, making it easier and quicker to put together.

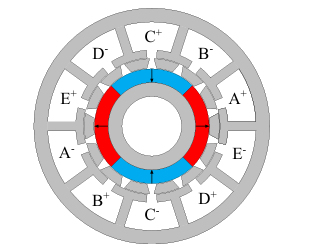

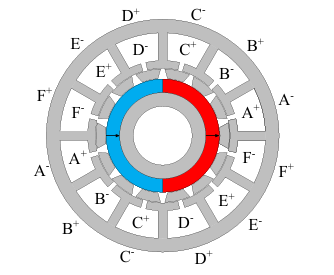

- Flexible Phase Configurations: This system can be set up in both 5-phase and 6-phase configurations, which allows it to be adapted for different machine requirements.

- Energy Efficient Operation: This product consumes less energy while still providing the same or better performance, which lowers running costs.

A working design has been created, and multiple configurations have been explored. The 5-phase setup uses 10 stator slots and 14 rotor segments, and the 6-phase version uses 12 stator slots with the same rotor segment count. The speed increase has been demonstrated in these prototypes, where for instance, one rotor spins 3.5 to 7 times faster than the other.

The motor design is at an advanced prototype stage. Functional layouts have been finalized, and performance configurations are clearly defined in the patent.

5

This invention helps solve important challenges in making electric motors cheaper, cleaner, and more efficient. It avoids the use of expensive and environmentally harmful rare-earth magnets. Since motors are used everywhere from electric vehicles to home appliances this design can lead to cost savings and energy efficiency on a wide scale. Additionally, by simplifying motor construction, it could promote local manufacturing and job creation, especially in developing economies where affordability and ease of production are crucial.

- Electric Vehicles

- Industrial Automation

- Robotics

- Clean Energy Systems

- Aerospace Equipment

- Smart Manufacturing

- Motor Control Systems

Geography of IP

Type of IP

202321082856

550125