The invention provides an impactor-based atomizer assembly comprising a tapered tube-in-tube nozzle designed to generate fine droplets through the combined action of air suction and liquid impingement. The system includes two micropipette tubes of unequal height inserted into a nozzle block, through which compressed air and liquid are directed toward an impactor plate placed inside a sealed atomization chamber. The setup allows stable atomization across a wide range of operating pressures without backflow or clogging. The modular design includes a manifold-fed control unit with bypass and drainage features, ensuring continuous operation, corrosion resistance, and scalability for laboratory and industrial applications.

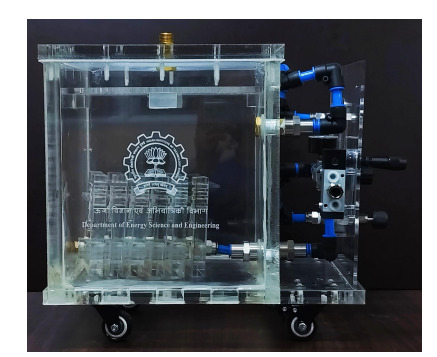

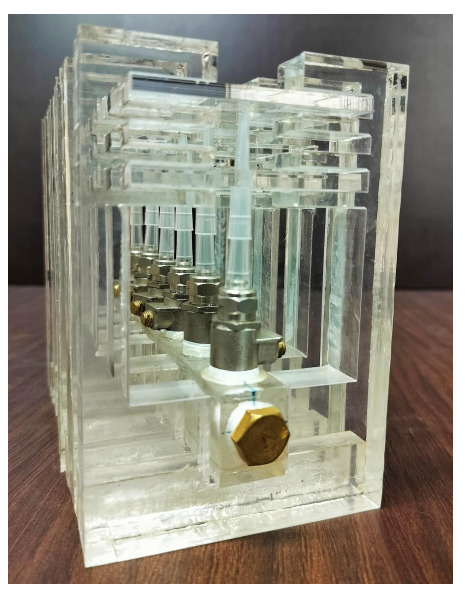

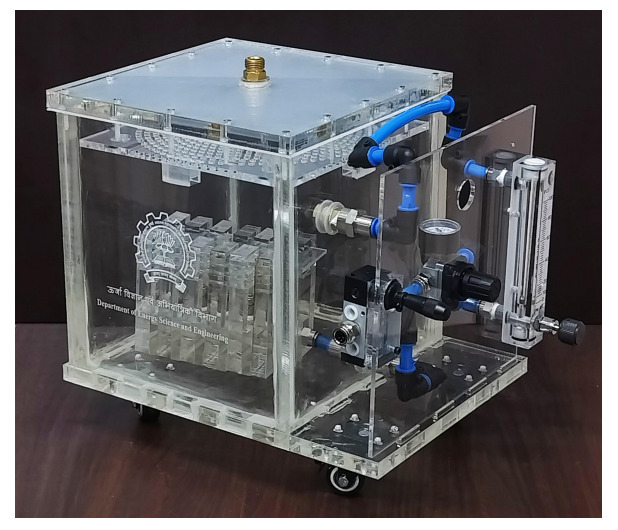

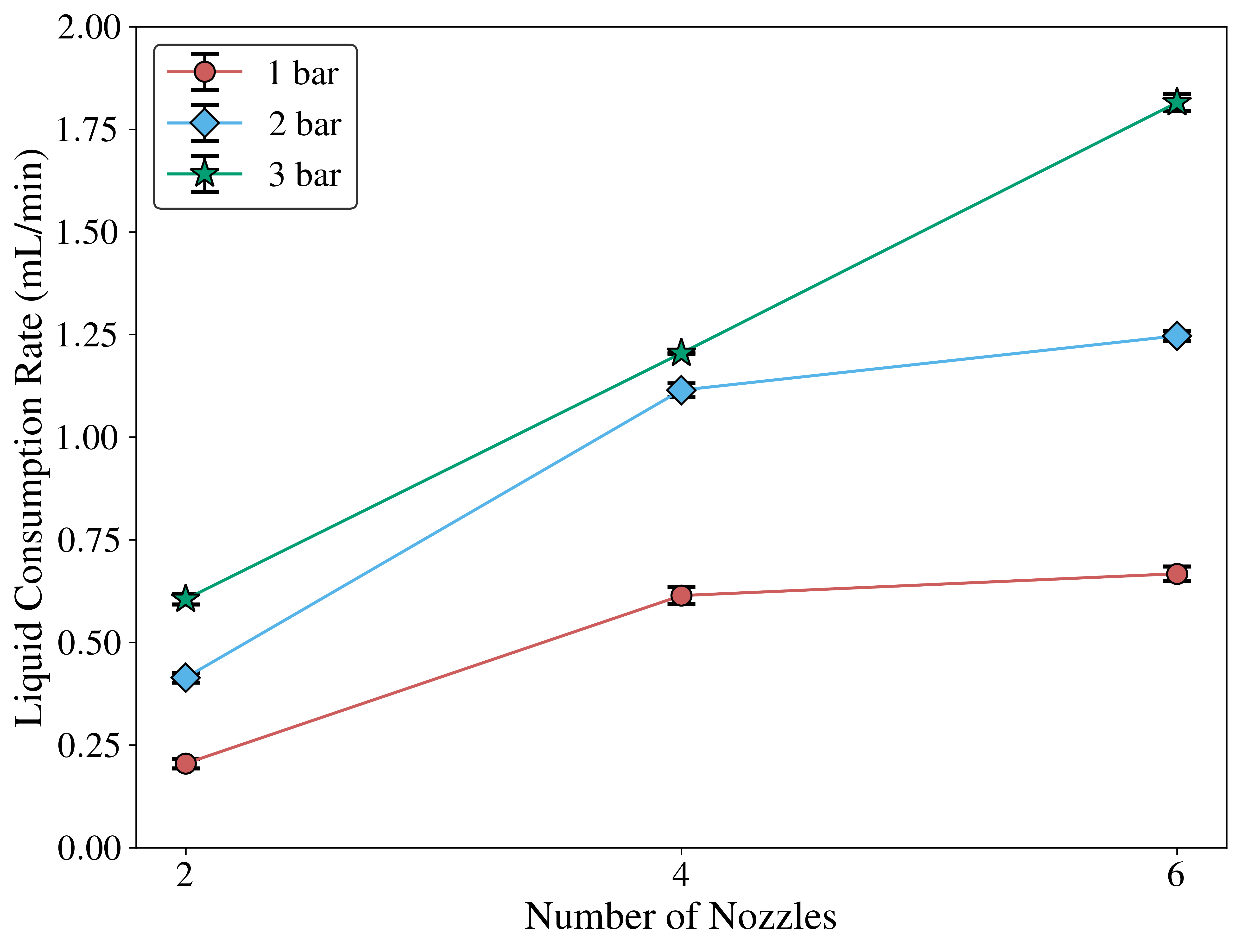

Figure (1) Atomiser – Front view; (2) Atomisation assembly; (3) Atomiser; (4) Under nominal laboratory conditions, using water as the atomizing medium, the atomizer assembly — equipped with four identical nozzles and supplied at 2 bar gauge air pressure — exhibited a liquid consumption rate of 1.11 mL/min (see Figure). Refer to the accompanying plot for the complete consumption‐rate profile across varying nozzle counts and supply pressures.

Conventional atomizers used for applications such as flow diagnostics, PIV, and aerosol generation often suffer from drawbacks including limited pressure range, non-uniform droplet size distribution, clogging, and corrosion when exposed to saline or reactive fluids. Many existing designs also require complex hardware and are not easily modular or scalable. Therefore, there is a need for a compact, corrosion-resistant, and modular atomizer system that can generate fine droplets with narrow size distribution across a wide range of operating pressures, while minimizing flow disruption and ensuring consistent atomization for reliable experimental and industrial use.

- Tube-in-Tube Nozzle: The atomizer uses two concentric micropipette tubes positioned at different vertical heights inside a nozzle block to introduce compressed air and liquid streams for effective mixing and suction.

- Impactor Plate Atomization: A strategically positioned impactor plate inside the atomization chamber breaks the air–liquid mixture into fine droplets by using mechanical shear and collision, ensuring uniform particle size.

- Wide Pressure Compatibility: The nozzle configuration, along with rotameter-controlled airflow, supports stable droplet formation across a pressure range of 15–90 psi, making it suitable for various laboratory and industrial conditions.

- Modular Supply Architecture: The design connects multiple nozzles to a common manifold through individual flexible tubing, allowing easy scalability and reconfiguration for multi-nozzle operation.

- Corrosion-Resistant Construction: The atomizer is constructed using stainless steel, brass, and acrylic components, enabling long-term usage with brine or salt-based liquids without corrosion or clogging.

- Continuous Flow Assurance: A bypass air line equipped with a rotameter and valve ensures uninterrupted air output from the compressor to maintain steady system operation when one or more nozzles are closed.

The prototype consists of a modular atomizer assembly featuring a control panel, a sealed atomization chamber, and a manifold-fed nozzle unit. The atomization unit comprises a brass nozzle block housing two micropipette tubes of different lengths, arranged in a tapered tube-in-tube configuration. These tubes deliver compressed air and liquid to a centrally positioned impactor plate within the chamber. The setup includes a bypass air line, rotameters, pressure regulators, and a two-way valve for directing airflow and maintaining continuous operation. The atomization chamber is made of acrylic with stainless steel connectors and a top-mounted drainage pipe. The prototype was tested with salt solutions at pressures ranging from 15 to 90 psi and validated using Mie scattering to confirm stable droplet formation and narrow size distribution.

A functional prototype of the impactor atomizer assembly has been successfully developed and tested. The system has been validated using Particle Image Velocimetry (PIV) experiments and image-based Mie scattering techniques, confirming consistent generation of fine droplets with a narrow size distribution (average ~3.4 µm) across a pressure range of 15–90 psi. The atomizer was tested with salt solutions to demonstrate corrosion resistance and stability under varying flow conditions. The modular setup, manifold-based supply, and bypass airflow system have been experimentally verified, confirming the atomizer’s effectiveness, scalability, and suitability for laboratory and industrial applications.

9

The impactor atomizer assembly offers a cost-effective, corrosion-resistant, and modular solution for generating fine liquid droplets, addressing limitations of conventional atomizers used in diagnostics and environmental studies. Its robust and scalable design enables accurate flow visualization, aerosol generation, and droplet-based research across academic, industrial, and field settings. By minimizing clogging and reducing maintenance, the technology enhances experimental efficiency and supports broader access to advanced fluid diagnostic tools in both resource-rich and resource-constrained environments.

- Fluid mechanics and flow visualization: The atomizer provides fine, uniform droplets ideal for seeding flow fields in experimental fluid dynamics studies.

- Particle Image Velocimetry (PIV) setups: It generates stable and narrowly distributed droplets required for high-resolution PIV measurements without clogging or instability.

- Environmental sampling and tracer injection: The system supports controlled delivery of tracer-laden droplets for atmospheric or pollutant dispersion studies.

- Combustion diagnostics: The atomizer can introduce fine liquid fuels or tracers into combustion chambers for flame structure and spray characterization.

- Agricultural and pharmaceutical spraying: Its ability to atomize saline and reactive solutions enables precision spraying applications in agrochemical and drug delivery research.

- Lab-scale aerosol studies: The assembly serves as a compact and modular platform for controlled generation of aerosols in laboratory environments.

Geography of IP

Type of IP

202321079550

556307