The invention relates to a composite for steel refining, comprising free calcium sulfide (CaS) microparticles, free iron, and a Fe–CaS network structure embedded with CaS microparticles. The composite is synthesized by melting a mixture of iron sulfide and calcium in a mild steel crucible at 1300°C, followed by controlled furnace cooling. This structure enables stable calcium delivery during steel processing, minimizing calcium vaporization and effectively modifying alumina inclusions. The composite can be introduced into molten steel in powder form or through cored wire, providing a practical and thermally stable solution for secondary steel refining.

In conventional steel refining, calcium is introduced through pure calcium or calcium-based alloys, which suffer from high reactivity, low boiling point, and poor solubility in molten steel. These limitations result in substantial calcium loss due to vaporization, reduced efficiency in alumina inclusion modification, and issues like nozzle clogging and low castability. Therefore, there is a critical need for a stable, efficient, and thermally robust composite material that can deliver calcium in a controlled manner, ensure effective inclusion modification, and enhance overall steel quality.

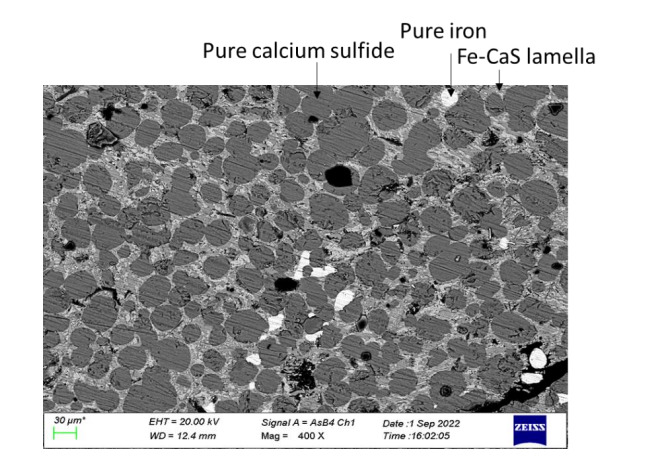

- Composite with Integrated CaS Microparticles: The material includes free CaS particles (10–100 µm), free iron, and a Fe–CaS network structure containing uniformly embedded CaS microparticles (1–20 µm).

- Enhanced Calcium Utilization: The design ensures longer residence time of active calcium in the melt, significantly minimizing vaporization losses and enabling sustained alumina inclusion modification.

- Stable Thermochemical Behavior: Unlike conventional calcium additives, the composite remains solid or semi-solid in steel melt and does not boil, enabling controlled and efficient interaction with alumina inclusions.

- Flexible Form and Application: It can be crushed into powder or filled into cored wires, allowing for both direct addition and wire injection into the steel melt using existing refining infrastructure.

- Scalable Preparation Method: It is synthesized by melting a mixture of calcium and iron sulfide at approximately 1300°C in a mild steel crucible, followed by controlled furnace cooling to obtain a stable solid composite.

The composite prototype was prepared by melting a stoichiometric mixture of iron sulfide and pure calcium (2.2:1 ratio) in a mild steel crucible at 1300°C for 20 minutes, followed by furnace cooling. The solid composite was extracted, characterized via SEM-EDS, and tested in molten steel refining trials. It was added to 800 g of iron melt treated with aluminum, and observed over 15–60 minutes, demonstrating partial to complete inclusion modification depending on residence time.

The composite has been successfully synthesized and tested at laboratory scale. Its effectiveness was validated through SEM-EDS analysis showing significant alumina modification into calcium aluminate and measurable sulfur pickup. Performance improved with longer treatment times (up to 60 minutes), confirming sustained reactivity and stability.

4

This invention addresses a critical challenge in secondary steel refining by enabling efficient and controlled delivery of calcium for alumina inclusion modification. By minimizing calcium loss due to vaporization and enhancing castability, the composite improves steel quality and reduces operational issues such as nozzle clogging. The technology offers a cost-effective and scalable alternative to existing calcium-based additives, contributing to more reliable, high-performance steel production. Its industrial adaptability supports sustainable metallurgy and improved resource efficiency in steelmaking operations.

- Steel refining and secondary metallurgy: The composite enables controlled calcium addition for refining molten steel and modifying non-metallic inclusions during secondary metallurgy.

- Deoxidation and inclusion control in molten steel: It effectively converts alumina inclusions into calcium aluminates, improving steel cleanliness and casting behavior.

- Wire injection metallurgy processes: The composite can be filled into cored wires for precise and stable calcium delivery via standard wire injection systems.

- Specialty and high-purity steel production: Its ability to reduce nozzle clogging and enhance inclusion modification makes it suitable for clean, high-performance steel grades.

- Industrial steel casting operations: The stable thermochemical behavior of the composite supports smoother casting by improving flow properties and reducing blockages.

Geography of IP

Type of IP

202221076794

559193