The invention provides a simplified control strategy for a double-inverter-fed wound rotor induction machine (DI-WRIM) using a dual volts-per-hertz (V/f) approach based on steady-state modeling. The control system regulates torque by manipulating the phase angle between stator and rotor voltage phasors. It eliminates the need for dynamic modeling, field-oriented control, and current sensors. A single PI controller is used along with a speed sensor to maintain closed-loop control. The system supports four-quadrant operation and enables a robust rotor short-circuited startup. The proposed method offers cost-effective, sensor-minimized, and reliable control for DI-WRIM systems in industrial and high-power applications.

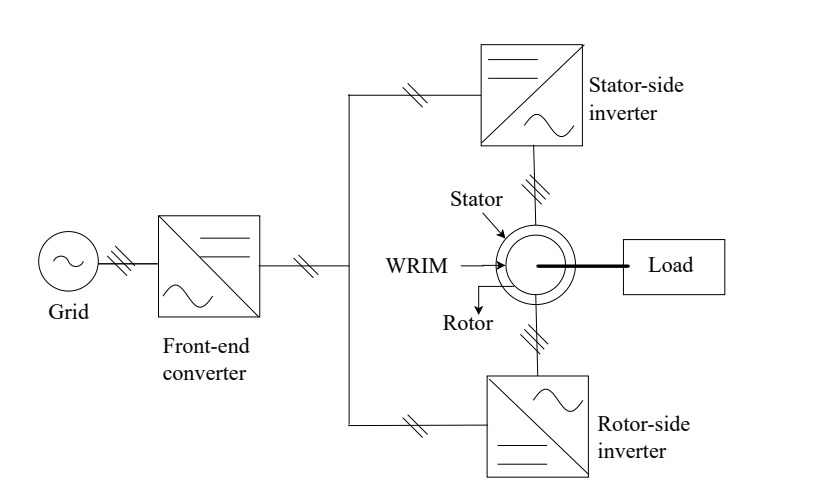

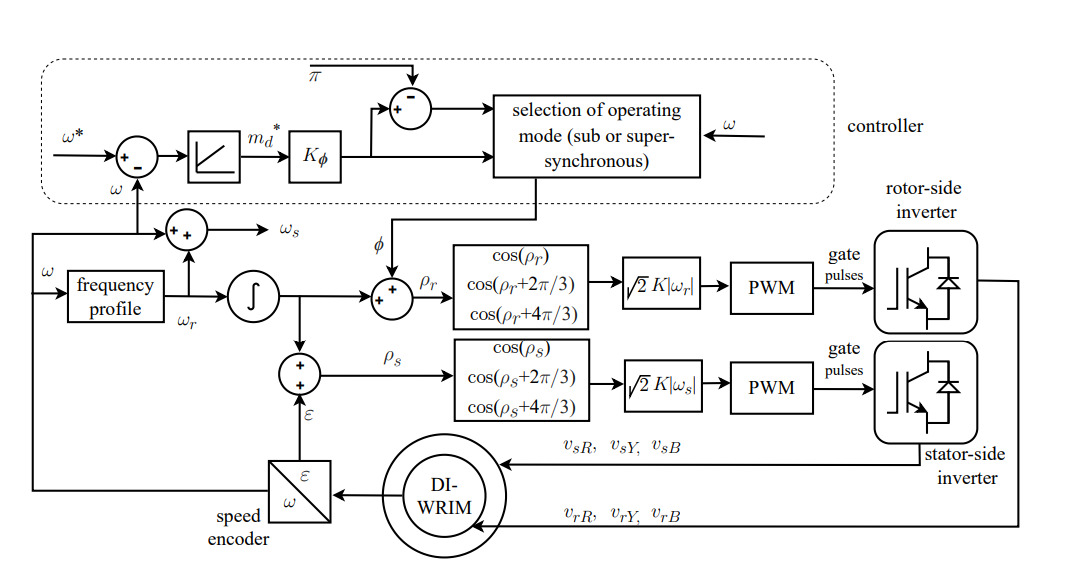

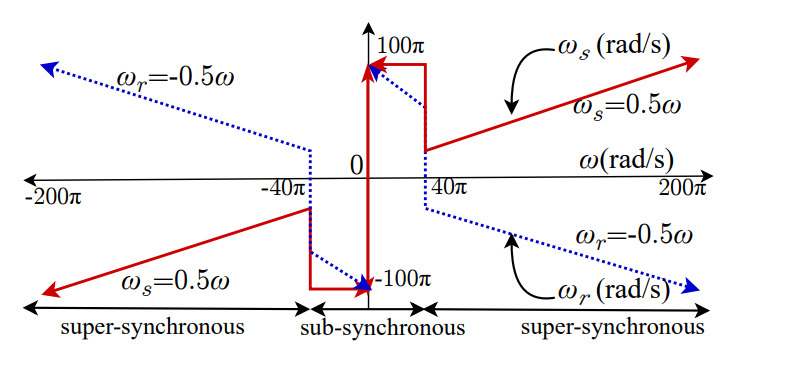

Figure (1) Block diagram of double-inverter-fed wound rotor induction machine drive; (2) Proposed scheme for dual volts-per-hertz control of double-inverter-fed wound rotor induction machine; (3) Frequency trajectories of stator and rotor supply frequencies (ωs and ωr) as rotor speed (ω) varies from −200π rad/s to 200π rad/s.

Conventional control strategies for double-inverter-fed wound rotor induction machines (DI-WRIM) are complex, relying heavily on dynamic models and requiring multiple sensors and controllers for torque and speed regulation. These methods increase hardware costs and are sensitive to parameter variations, making them less suitable for practical industrial deployment. There is a need for a simplified, sensor-minimized, and robust control approach that ensures stable torque control and supports four-quadrant operation without relying on field-oriented control or dynamic modeling.

- Steady-State Based Dual V/F Control: The invention eliminates the need for dynamic modeling and field-oriented control by implementing a simple steady-state V/f strategy for both stator and rotor inverters.

- Linear Torque Control Mechanism: The control uses the phase angle between stator and rotor voltage phasors as a direct and linear input to modulate torque output.

- Single PI Controller Integration: The control architecture is significantly simplified by using one proportional-integral controller to regulate both speed and torque, reducing computational complexity.

- Seamless Mode Transitions: It allows automatic and smooth transitions between motoring and generating modes in both sub-synchronous and super-synchronous regions with minimal current disturbance.

- Parameter Variation Immunity: The method maintains stable performance and accurate control even when motor parameters such as resistance or inductance vary during operation.

- No Current Sensor Required: The system achieves closed-loop control without relying on stator or rotor current feedback, thereby reducing sensor cost and hardware requirements.

- Reliable Rotor Short-Circuited Start-Up: A reliable start-up scheme is provided that initializes the motor without rotor voltage commands, preventing inrush currents and eliminating the need for rotor position estimation.

A hardware prototype of the double-inverter-fed wound rotor induction machine (DI-WRIM) system was developed, consisting of two voltage source inverters—one each for the stator and rotor circuits—connected via a common DC bus. The stator and rotor inverters were independently controlled using a steady-state dual volts-per-hertz strategy. A single proportional-integral (PI) controller was implemented to achieve closed-loop speed control based on feedback from a speed encoder. The phase angle between stator and rotor voltage phasors was used as a control variable for torque regulation. Experimental results validated the system’s ability to operate reliably across all four quadrants (motoring and generating modes in sub- and super-synchronous regions) and demonstrated smooth startup using a rotor short-circuited mode. The prototype confirmed that the system functions effectively without relying on current sensors or dynamic modeling.

The proposed control scheme has been implemented and experimentally validated on a laboratory prototype of a double-inverter-fed wound rotor induction machine. The system has demonstrated stable performance under speed and load variations, including seamless four-quadrant operation and effective rotor short-circuited startup. Hardware results confirm that the control approach operates without current sensors or dynamic models, and provides consistent torque regulation through voltage phase angle control. The technology is ready for scale-up and adaptation in industrial drive applications.

6

The invention offers a simplified and cost-effective control strategy for wound rotor induction machines by eliminating the need for complex dynamic modeling, current sensors, and multiple controllers. This enables wider adoption of energy-efficient and robust electric drives in cost-sensitive and resource-limited industrial settings. By supporting four-quadrant operation with minimal hardware and computation, the technology promotes accessible and sustainable electrification in sectors such as transportation, renewable energy, and automation, contributing to improved energy use and reduced environmental impact.

- Electric Vehicle and Traction Systems: The control method is suitable for propulsion systems requiring efficient torque control and four-quadrant operation without complex feedback mechanisms.

- Renewable Energy Systems: It can be applied in wind turbine generators and similar systems where variable speed operation and energy recovery are critical.

- Industrial Motor Drive Applications: The invention supports simplified control of wound rotor induction machines used in variable-frequency drive (VFD) systems for industrial automation.

- Power Generation and Grid-Tied Machines: The scheme enables stable operation of machines that operate across synchronous speeds, including those connected to power grids.

- Aerospace and Marine Propulsion Drives: The robust, sensor-minimized architecture makes it applicable in environments where reliability and compact control are essential.

Geography of IP

Type of IP

202321015672

563855