This invention presents a dual-sided superhydrophobic Laser-Induced Graphene (LIG) surface for energy-efficient desalination and brine treatment. The top PVDF-LIG and bottom modified PES-LIG layers enable continuous interfacial evaporation using solar or electrical energy. The design prevents salt scaling, supports backward salt diffusion, and maintains high evaporation rates even with concentrated brine, offering a scalable and sustainable solution for brine management.

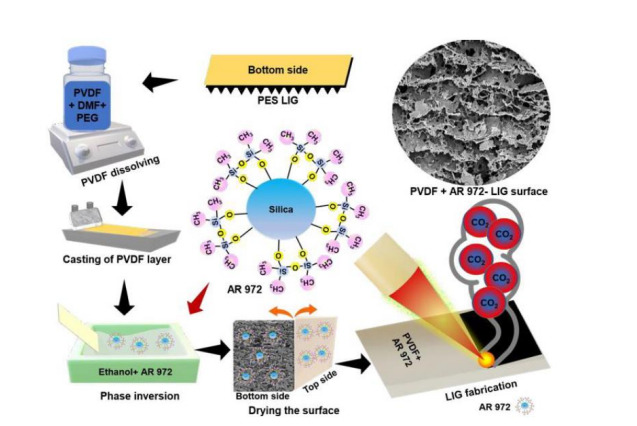

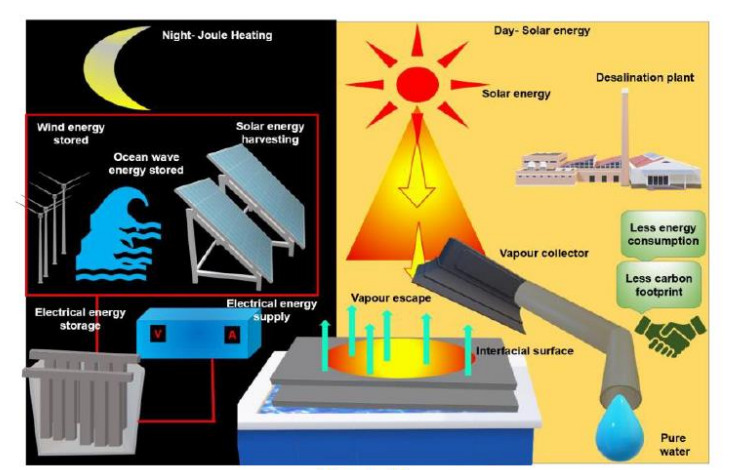

Figure (1) The illustration of the fabrication of the PVDF-modified fumed silica (Aerosil R 972) layer on the bottom side of PES-LIG followed by LIG fabrication; (2) Scheme; brine from desalination plants can be collected and evaporated utilizing interfacial surface on solar energy during day time and electrical energy during night time.

Conventional desalination methods often struggle with the efficient treatment of high-salinity brine due to issues like salt scaling, energy-intensive processes, and limited reusability of treatment surfaces. There is a pressing need for innovative solutions that can enhance evaporation efficiency, prevent salt accumulation, and maintain performance over multiple cycles, especially when dealing with hypersaline conditions.

- Advanced Surface Design: This invention features a dual-layered superhydrophobic surface with Laser-Induced Graphene (LIG) on both PVDF and PES substrates, modified with hydrophobic fumed silica. This design creates forest-like microstructures that enhance water repellence and support efficient interfacial evaporation. The structure effectively resists salt intrusion and pore blockage.

- Photothermal and Electrothermal Capability: The dual-sided LIG surface is engineered for operation with both solar energy and low-voltage Joule heating. Laser scribing enables photothermal conversion, while its electrical conductivity supports electrothermal operation. These features facilitate fast, continuous evaporation, ensuring high thermal efficiency with minimal heat loss.

- High Performance Under Salinity Stress: The surface demonstrates stable evaporation even with highly concentrated saline solutions (up to 24 wt% NaCl). Hydrophobic modification prevents salt penetration and facilitates backward diffusion, preventing salt buildup. Extended operation shows no significant salt crystal formation, highlighting its robust performance.

- Durability and Reusability: This advanced surface maintains its superhydrophobicity and functional performance over repeated cycles. Both layers resist degradation under high salinity, and the laser-engraved graphene structures remain intact. The system shows negligible salt deposition and stable evaporation across multiple uses, proving its long- term viability.

- Scalable Fabrication: The device is fabricated using standard polymer casting and CO₂ laser scribing techniques, requiring no special atmospheric conditions or exotic materials. This method is cost-effective and suitable for large-scale production, enabling easy deployment near desalination plants or in off-grid locations.

The prototype consists of a dual-sided superhydrophobic surface fabricated using Laser-Induced Graphene (LIG) on polyether sulfone (PES) and polyvinylidene fluoride (PVDF) substrates. The bottom PES layer is first cast using a 15 wt.% dope solution in NMP and subjected to non-solvent-induced phase separation (NIPS) in water, followed by CO₂ laser scribing to form the LIG surface. A PVDF layer (16 wt.%) containing 0.15 wt.% hydrophobic fumed silica is then cast on the opposite side and coagulated in ethanol containing silica particles. This results in the embedding of silica in both the PVDF layer and PES substrate. Laser scribing is subsequently performed on the PVDF surface to form the top LIG layer. Both layers exhibit superhydrophobicity (~156°–157° contact angle) and electrical conductivity.

The prototype was tested under solar, electrical (3.5–7.5 V), and combined energy inputs. Evaporation performance was evaluated with deionized water and NaCl solutions (3.5–24 wt.%). The surface demonstrated stable, continuous interfacial evaporation with no visible salt scaling, maintaining high efficiency even at saturation salinity. The device was further validated in stacked configurations and showed enhanced evaporation and thermal efficiency, confirming its potential for scalable, low-energy brine treatment applications.

A lab-scale prototype has been successfully fabricated and tested using solar, electrical, and combined energy sources. The system demonstrates stable evaporation and salt resistance up to 24 wt% NaCl. All fabrication steps are reproducible, and performance has been validated in stacked configurations, confirming scalability and operational reliability.

4

The technology enables sustainable brine treatment by reducing salt discharge and energy consumption in desalination. Its solar and low-power operation makes it ideal for remote or resource-limited areas. This supports clean water access while minimizing environmental impact from brine disposal.

- Desalination plants

- Brine management and zero-liquid discharge systems

- Solar-powered water treatment units

- Remote and off-grid water purification setups

- Industrial wastewater evaporation systems

- Renewable energy-integrated environmental technologies

- Sustainable water infrastructure and reuse solutions

Geography of IP

Type of IP

202421013633

554002