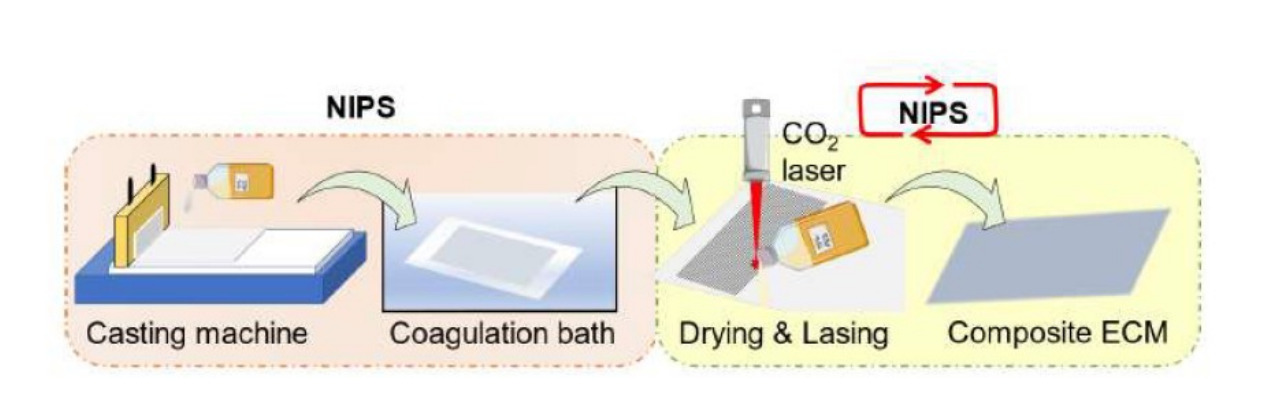

This invention presents a novel fabrication method for electroconductive ultrafiltration (UF) membranes made from Poly-ether Sulfone (PES) and Laser-Induced Graphene (LIG). Using a CO₂ laser on PES membranes, LIG is generated in-situ, followed by a NIPS process to coat with additional PES, creating a layered composite with asymmetric pores. These membranes combine filtration with electrochemical treatment to remove contaminants like Cr(VI) effectively.

Conventional membrane technologies face limitations such as fouling, limited selectivity, and poor removal of toxic contaminants like Cr(VI). Existing electroconductive membranes are often costly and complex to fabricate, making them unsuitable for scalable water treatment. There is a critical need for an affordable, efficient, and multifunctional membrane capable of simultaneous filtration and contaminant removal.

- Innovative Electroconductive Membrane Design: The invention uses a CO₂ laser to generate Laser-Induced Graphene (LIG) directly on a Poly-ether Sulfone (PES) membrane, forming an electroconductive surface without any chemical additives.

- Multifunctional Performance: The membrane enables simultaneous filtration, electrochemical reduction, and precipitation of pollutants like Cr(VI), achieving up to 94% removal under applied voltage.

- Tunable Pore Structure and Surface Properties: The membrane’s pore size and thickness are controlled by varying PES concentration and casting height, allowing optimization of flux, rejection, and surface roughness.

- Stable Electrochemical Conductivity: The composite membrane retains conductivity even after mechanical stress and sonication, ensuring reliable electrochemical performance during operation.

- Surface Hydrophilicity and Antifouling Characteristics: The presence of LIG enhances surface hydrophilicity, resulting in lower contact angles, better antifouling performance, and high flux recovery after cleaning.

- Cost-Effective and Scalable Fabrication: The method uses affordable PES and eliminates the need for expensive additives like CNTs, making the process suitable for roll-to-roll industrial fabrication.

- Compatibility with Electrochemical Filtration Systems: The membrane functions as a cathode in electrochemical systems, allowing effective removal of charged contaminants in cross-flow filtration setups.

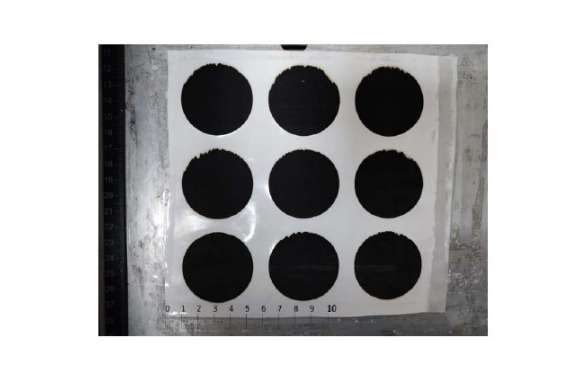

The prototype comprises composite ultrafiltration membranes fabricated using Poly-ether Sulfone (PES) and Laser-Induced Graphene (LIG). A 15 wt% PES solution was cast on a polyester support using the Non-Solvent Induced Phase Separation (NIPS) method to form the base membrane. LIG was generated in situ by irradiating the dried PES surface with a CO₂ laser under optimized parameters. This LIG-coated surface was then overlaid with PES solutions of varying concentrations (12.5%, 15%, and 17.5%) to form composite membranes of different thicknesses (100, 200, and 300 µm). The membranes were tested under both dead-end and cross-flow filtration setups. Performance metrics included water flux, protein rejection, Cr(VI) removal, molecular weight cut-off, antifouling, and anti-biofouling properties. Characterization was conducted using SEM, FTIR, Raman spectroscopy, AFM, XPS, and contact angle measurements. Electrochemical tests confirmed Cr(VI) removal up to 94% at 5V with 100 mM electrolyte, validating the membrane's electroconductive filtration capability.

The PES-LIG composite membrane has been fabricated and tested at the lab scale. It demonstrates high Cr(VI) removal efficiency (up to 94%) under applied voltage, good mechanical and electrochemical stability, and excellent antifouling recovery performance.

4

This technology offers a promising solution for decentralized water treatment, especially in resource-limited or rural settings. Its ability to remove hazardous contaminants like Cr(VI) without generating sludge or requiring chemical regeneration contributes to safer drinking water and public health.

- Water and wastewater treatment

- Decentralized water purification

- Electrochemical water purification systems

- Environmental remediation

- Chemical and process industries

- Automotive cooling systems

- Industrial effluent treatment

Geography of IP

Type of IP

202421002146

551677