The invention discloses a single-step process for fabricating a hydrophilic elastomer sponge by mixing PDMS, a hydrophilic copolymer (PDMS-b-PEO), and a leavening agent such as yeast. Upon curing, the sponge exhibits uniform porosity and durable hydrophilicity throughout its bulk without requiring post-treatment. The material can be rendered conductive using a dip-and-dry technique, making it suitable for applications such as flexible pressure sensors, biomedical scaffolds, and fluidic devices.

Conventional methods for fabricating hydrophilic elastomeric sponges often involve multi-step processing, external templates, and post-treatment techniques such as plasma or solvent exposure, which only impart temporary surface hydrophilicity. These approaches are not scalable, are costly, and fail to achieve durable and uniform hydrophilicity throughout the material. There is a need for a simple, single-step process that enables the fabrication of porous elastomeric sponges with inherent and long-lasting hydrophilic properties for use in flexible sensing, filtration, and biomedical applications.

- Single-Step Fabrication Process: Hydrophilic, porous PDMS sponge is produced in one step by incorporating a hydrophilic co-polymer and a leavening agent into the base elastomer.

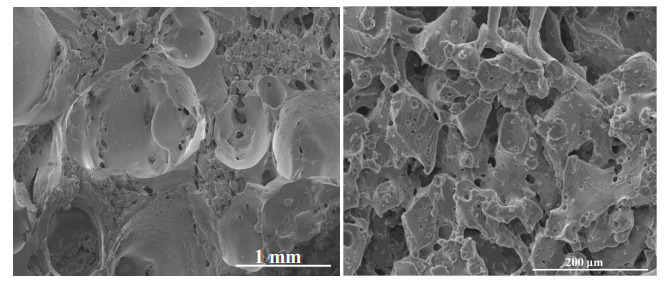

- Integrated Hydrophilicity and Porosity: The simultaneous introduction of hydroxyl-rich copolymer and pore-forming yeast leads to long-lasting hydrophilicity throughout the sponge volume.

- No Post-Treatment Required: It eliminates plasma treatment or solvent-mediated hydrophilization, simplifying process flow and enhancing durability.

- Versatile and Cost-Effective: It Utilizes readily available PDMS, yeast, and DI water without needing metallic templates or vacuum impregnation methods.

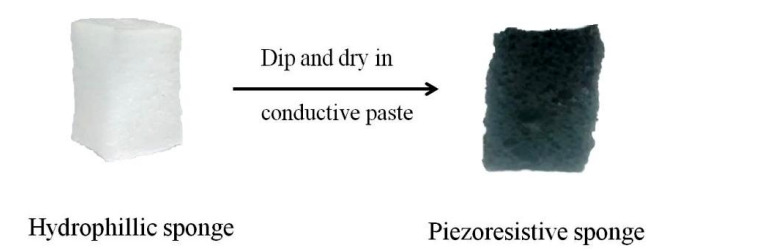

- Pressure Sensor Compatible: The sponge can be made conductive using dip-and-dry method, yielding reliable resistance response under compression cycles.

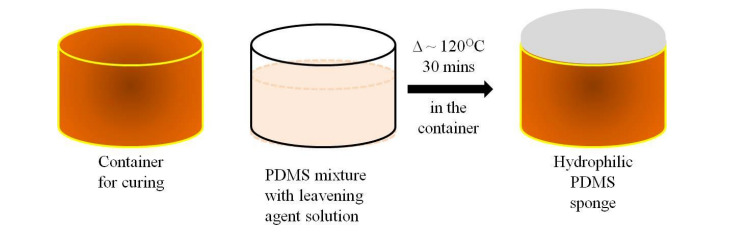

The prototype sponge was fabricated using a 10:1 ratio of PDMS base to curing agent, blended with 4–8 wt% PDMS-b-PEO copolymer. A yeast–water emulsion was added dropwise to the elastomer mixture, followed by thorough mixing. The composite was poured into molds and cured at 120°C for 30 minutes to form a porous, hydrophilic sponge. To impart conductivity, the sponge was subjected to three cycles of dip-and-dry treatment using a commercial water-based conductive ink, with each drying step conducted at 60°C. The conductive sponge was integrated into a pressure sensing setup and tested over 50 mechanical loading cycles, showing consistent resistance response, high gauge factor, and full recovery of shape and signal after deformation.

The technology has been successfully demonstrated at the lab scale. The sponge has been fabricated using a 10:1 PDMS base:curing agent ratio with 4–8 wt% PDMS-b-PEO and yeast. Conductivity has been introduced using commercial conductive ink, and pressure sensing functionality has been verified over 50 compression cycles with consistent signal stability and mechanical resilience.

4

This invention offers a simple, scalable, and low-cost solution for producing hydrophilic elastomeric sponges with durable functionality, eliminating the need for temporary or complex post-processing. Its ability to serve as a flexible, compressible, and conductive material makes it valuable for applications in wearable sensors, healthcare monitoring, water purification, and environmental remediation. By utilizing benign materials and avoiding hazardous treatments, the technology aligns with sustainable manufacturing and broadens access to soft electronic systems and filtration tools in both developed and resource-limited settings.

- Pressure Sensing in Wearable Electronics: The conductive sponge responds sensitively to mechanical deformation, making it suitable for integration into flexible pressure sensors.

- Biomedical Diagnostics and Implants: Its soft, porous, and hydrophilic nature makes the material ideal for biosensing, tissue scaffolding, and implantable diagnostic devices.

- Soft Robotics and Touch-Sensitive Systems: The compressible and responsive sponge structure enables tactile sensing and feedback for soft robotic interfaces.

- Water Filtration and Oil–Water Separation: The intrinsic hydrophilicity and porosity allow selective absorption and separation in environmental filtration systems.

- Microreactors and Micromixing Platforms: The sponge’s interconnected pores facilitate efficient mixing and controlled flow in lab-on-chip or chemical processing setups.

- Flexible and Conductive Elastomer Materials: The material serves as a stretchable, conductive platform for use in soft electronics and embedded circuit applications.

Geography of IP

Type of IP

201821014916

380455