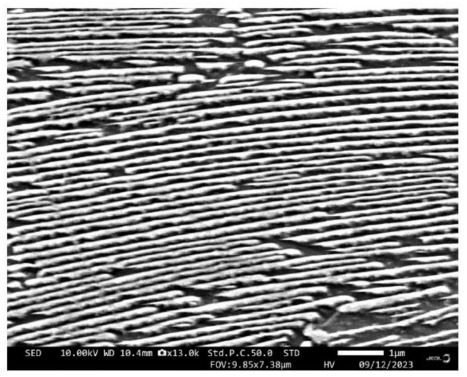

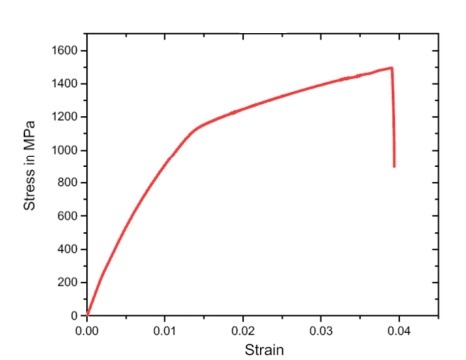

The present invention relates to 100% pearlitic internal microstructure having an average mean true interlamellar spacing as low of 70 nm and in the range of 150-70 nano-meters have been produced in bulk by austenitization at 980°C to 1020°C for a period between 45 minutes to 75 minutes and isothermal transformation between 725°C-550°C for a period between 120 mins to 270 mins. The present invention more particularly relates to a type of steel grade, which by virtue of its composition and a unique heat treatment can lead to formation of bulk nano-pearlitic microstructure with average inter-lamellar spacing interlamellar spacing in the range of 150-70 nm; capable of rendering hardness of the resulting steel block is between 400-422 HV with yield strength in the range of 1100 MPa to 1150 MPa, the ultimate tensile strength above 1425 MPa to 1500 MPa and tensile ductility in the range of 6% to 10%.

Existing pearlitic steels for railway use struggle to achieve optimal hardness, strength, toughness, and wear resistance due to coarse interlamellar spacing and non-ideal alloy compositions. Current nano-structured pearlitic steels either have interlamellar spacing outside the 70–150 nm range or rely on costly alloying elements, limiting large-scale use. Therefore, a steel composition and heat treatment process is needed to produce bulk nano-structured pearlitic steel with controlled interlamellar spacing, delivering superior mechanical properties for high-speed railway wheels and rails.

- Exceptional Microstructure: Nano-structured pearlitic steel with exceptionally fine interlamellar spacing of 70 to 150 nm, which is difficult to achieve using conventional steel compositions and heat treatments.

- Superior Mechanical Properties: Exhibits hardness between 400 and 422 HV, yield strength from 1100 to 1150 MPa, and ultimate tensile strength ranging from 1425 to 1500 MPa, combined with good tensile ductility of 6% to 10%.

- Innovative Alloy Composition: Incorporates optimal amounts of carbon, aluminum, chromium, cobalt, manganese, molybdenum, and silicon to stabilize and refine the pearlitic microstructure.

- Unique Thermo-Mechanical Processing: Employs precise austenitizing and isothermal transformation steps that enable controlled microstructural evolution for enhanced performance.

- Cost-Effective Production: The process uses standard industrial equipment like muffle furnaces and forging presses, making it economically viable for large-scale manufacturing.

- Enhanced Performance over Prior Art: Demonstrates superior strength and hardness while maintaining comparable or improved ductility compared to existing steel technologies.

This invention describes a nano-structured pearlitic steel produced from a specific alloy composition: C (0.77-0.79 wt%), Al, Cr, Co, Mn, Mo, Si, with trace P and S, and balance Fe. The process includes casting into sand molds, optional homogenization, and hot forging at 950°C–1050°C with 60%-70% thickness reduction. Forged blocks are austenitized at 980°C-1020°C for 45-75 minutes, followed by isothermal transformation at 550°C-725°C for 120-270 minutes, then air-cooled. This yields a fully pearlitic microstructure with 70-150 nm interlamellar spacing and superior properties: hardness (400-422 HV), yield strength (1100-1150 MPa), UTS (1425-1500 MPa), and ductility (6%-10%). Standard industrial tools-muffle furnaces, a 500-ton press, SEM, and tensile testers-were used for fabrication and testing.

TRL 6

6

This nano-structured pearlitic steel offers enhanced performance for safer, longer-lasting components in automotive, aerospace, and infrastructure sectors. Its high strength-to-weight ratio reduces material use, saving energy and lowering carbon emissions in manufacturing and transport. Supporting sustainable development, it enables lightweight, durable products that improve fuel efficiency while driving innovation and economic growth in advanced steel manufacturing.

- Automotive Components

- Aerospace Structures

- Railway and Transportation Systems

- Tool and Die Manufacturing

- Construction and Infrastructure Materials

Geography of IP

Type of IP

202421021491

557657