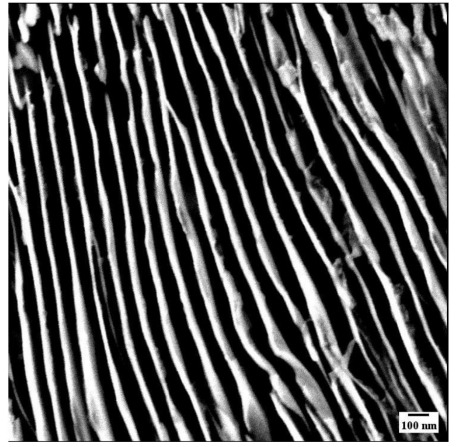

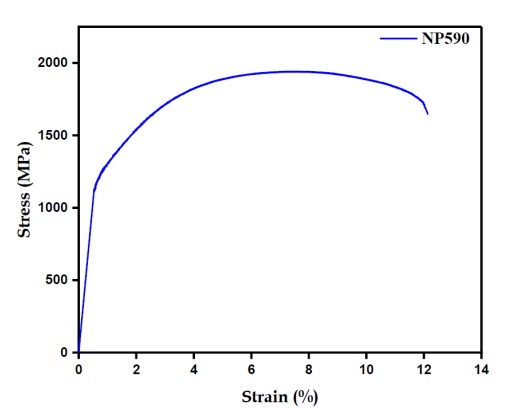

The present invention relates to High strength Nano-structured pearlitic steel having an interlamellar spacing in the range of 60–135 nm have been produced in bulk by austenitization at 1000°C to 1200°C for a period between 1 hour to 2.6 hours and isothermal transformation between 580°C–730°C for a period between 40 mins to 120 mins. The present invention more particularly relates to a type of steel grade, which by virtue of its composition and unique heat treatment can lead to the formation of bulk nano-pearlitic microstructure with average inter-lamellar spacing interlamellar spacing in the range of 60–135 nm; capable of rendering hardness of the resulting steel block is between 340 HV to 425 HV with yield strength in the range from 1 GPa to 1.2 GPa, ultimate tensile strength in the range from 1.6 GPa to 2 GPa and tensile ductility in the range of 12% to 14%.

Existing pearlitic steels for railway use struggle to balance strength, toughness, and wear resistance due to limited control over interlamellar spacing. Current compositions rely on high carbon or costly alloys, and heat treatments often produce microstructures that compromise performance or increase complexity. There is a need for nano-structured pearlitic steel with interlamellar spacing of 60–135 nm that delivers yield strength of 1.0–1.2 GPa and ultimate tensile strength of 1.6–2.0 GPa via a cost-effective, scalable heat treatment, improving durability and reliability in railway components.

- Nano-scale Pearlitic Microstructure: The nano-scale pearlitic microstructure achieves exceptionally fine interlamellar spacing of 60 to 135 nm, which is difficult to obtain in bulk steel through conventional processing.

- Optimized Chemical Composition: The unique combination of elements (C, Al, Cr, Co, Mn, Si, Mo, S, P) may be tailored to achieve superior mechanical and microstructural properties.

- Controlled Thermo-mechanical Processing: The precise austenitization and isothermal transformation heat treatments enable the development of a fully nano-structured pearlitic phase.

- Superior Mechanical Properties: Its high yield strength (1.0–1.2 GPa), ultimate tensile strength (1.6–2.0 GPa), and ductility (12%–14%) make it stronger and tougher than existing steels with similar hardness.

- Enhanced Fatigue, Wear, and Fracture Resistance: It improves durability and service life in demanding mechanical applications.

- Bulk Manufacturing Capability: The process is scalable for industrial production of large steel blocks or rails.

- Improved Hot Rolling and Homogenization Techniques: It prevents texture dominance and macro segregation, ensuring consistent quality.

The nano-structured pearlitic steel was produced by casting a steel composition—including 0.71–0.73 wt% Carbon, 1.5–1.6 wt% Aluminum, 1.4–1.5 wt% Chromium, 2.6–2.7 wt% Cobalt, and other alloying elements—into a slab measuring 170 × 70 × 70 mm using a vacuum induction furnace. A section of 105 × 65 × 32 mm was homogenized at 950°C–1050°C for 48–72 hours to eliminate macro segregation, followed by hot rolling at the same temperature range to achieve 60%–75% thickness reduction with cross rolling and intermittent reheating to prevent texture dominance. The rolled steel underwent heat treatments: austenitization at 1000°C–1200°C for 1–2.6 hours and isothermal transformation at 580°C–730°C for 40–110 minutes, with rapid transfer between furnaces under 10 seconds, before air cooling. The resulting fully pearlitic microstructure exhibited fine interlamellar spacing of 60-135 nm and superior mechanical properties, including yield strength of 1.0–1.2 GPa and ultimate tensile strength of 1.6–2.0 GPa.

6

The development of this nano-structured pearlitic steel enhances the safety, durability, and reliability of critical infrastructure such as high-speed railways, reducing accidents and maintenance costs. Its superior wear and fatigue resistance extend the lifespan of steel components, promoting resource efficiency and sustainability by minimizing waste. This technology also supports economic growth by enabling advanced domestic steel manufacturing and fostering innovation, contributing to safer, more efficient, and environmentally responsible engineering solutions.

- Railway industry

- Automotive industry

- Heavy Machinery and construction

- Aerospace industry

Geography of IP

Type of IP

202421014480

562845