This invention applies to shields for attenuating shock waves and more particularly, to a single or multiple-layered shield made of single material in which cell density distribution is changed across a thickness thereof for attenuating shock waves. The shield includes a single or multiple layered shield structure. The shield collapses partially and reduces propagation of plastic waves to the target being protected. The shield has high strength and is lightweight. The shield is inexpensive and is easy to manufacture.

Conventional blast protection methods use high-mass materials or uniform-density metallic foams to reduce shock wave impact but often fail under high-pressure conditions. Uniform foams may collapse and amplify stress, while multi-layered, density-graded foams are costly, complex to manufacture, and suffer from bonding issues. There is a need for a lightweight, efficient, and cost-effective shield that attenuates shock waves by optimizing energy absorption and minimizing transmitted stress – without relying on complex multi-material structures.

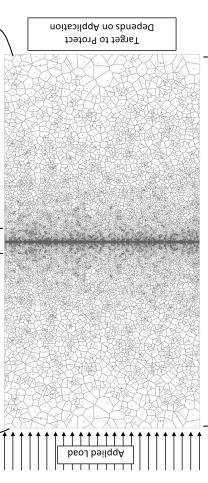

- Functionally Graded Cell Density Distribution: The shield employs a continuous, Gaussian-based variation of cell density across its thickness, with higher density near the center and lower density towards the edges, allowing optimized attenuation of shock waves.

- Single-Material Graded Foam Design: Unlike conventional multi-layer foams requiring adhesives and complex fabrication, this technology uses a single material with a graded structure, simplifying manufacturing and reducing costs.

- Effective Shock Wave and Plastic Wave Attenuation: The shield reduces transmitted shock wave stress by up to 58% through controlled collapse and by acting as an elastic barrier to disrupt plastic wave propagation, preventing stress amplification on protected targets. Numerical models confirm this superior attenuation compared to uniform density foams, proving enhanced performance.

- Lightweight and High-Strength Construction: Using metallic foams that are both strong and light, the shield offers efficient energy absorption while minimizing weight, ideal for personal protective equipment and structural applications.

- Cost-Effective and Easy to Manufacture: The single-material graded foam eliminates the need for complex multi-layer assembly, resulting in a cost-effective and scalable solution.

- Versatile Applications: It is suitable for use in combat helmets, body armor, vehicle underbellies, building facades, and delicate packaging, demonstrating broad protective utility.

The shield for shock attenuation consists of a single or multiple layered structure made from a single material, graded metallic foam, with cell density varying across its thickness. This density gradient is highest at the center and decreases towards the edges, designed by a specific Gaussian distribution formula. The shield partially collapses under shock, reducing plastic wave propagation and attenuating shock waves. It is lightweight, strong, cost-effective, and easy to manufacture. Tested numerically, the graded density foam demonstrated significant reduction in transmitted shock stress compared to uniform foams, making it suitable for protective applications such as combat gear, vehicle armor, and blast-resistant building panels.

Significant progress made towards development and initial validation of the study:

- Computational Evidence: Comprehensive computational evidence demonstrating the effectiveness of the foam-based shield in attenuating shock waves has been obtained.

- Lab Scale Experimental Validation: A few samples have been tested in a controlled environment (shock-tube setup) that complement the computational observations.

We plan to take the following steps next:

- Repeatability of experimental findings: Repeatability of the tests and verification of the shield’s effectiveness for different gradients and peak pressures.

- Full scale and field testing: Final proof will be provided by building full-scale shields and testing them against real blasts in the field.

3

This functionally graded metallic foam shield enhances safety by providing effective, lightweight, and affordable blast protection for military personnel, civilians, and infrastructure. It reduces injuries and damage from explosions, increases resilience, and lowers recovery costs. Its accessibility supports faster disaster response and improved public safety, benefiting society by mitigating the impact of blasts and attacks.

- Defense and Military: Used in body armor, helmets, and vehicle blast shields to protect personnel and equipment from explosions

- Automotive and Aerospace: Integrated into crash zones or aircraft panels to absorb impact and reduce structural damage

- Infrastructure Protection: Applied in building facades, pipelines, and transport hubs to mitigate damage from blasts or attacks

- Logistics and Packaging: Protects sensitive equipment and ammunition during transport from shock or accidental detonation

- Disaster Response and Rescue: Enhances safety in shelters and gear used by first responders in hazardous or blast-prone areas

Geography of IP

Type of IP

202321055277

560346