The present invention relates to a process for recovering lithium. Particularly, the present invention relates to a process for recovering lithium from spent lithium iron phosphates of lithium-ion batteries. The process comprises the steps of obtaining a spent lithium-ion battery; obtaining cathodic layer from the obtained battery; dipping the cathodic layer in a KOH solution; obtaining Lithium Iron Phosphate flakes by filtration of the solution; delithiation by mixing the obtained Lithium Iron Phosphate with Potassium Persulfate (K2S2O8) to obtain LiSO4, and cooling the obtained LiSO4 and adding Na3PO4 and filtering to obtain Li3PO4.

Efficient recovery of lithium from spent Lithium Iron Phosphate (LFP) batteries is challenging due to complex battery structures, low lithium leaching efficiency, lengthy processing times, and contamination by impurities. Traditional processes involve multiple leaching steps, use of expensive oxidants, and long delithiation times, making lithium recovery costly and inefficient.

- Efficient Single-Step Leaching with Ultrasonication: The process utilizes ultrasonication to assist the leaching of Lithium Iron Phosphate (LFP) in a single step, significantly reducing the concentration of alkaline leachant required. This results in faster lithium extraction with higher efficiency and less chemical usage.

- Cost-Effective Use of Potassium Persulfate as Oxidant: Potassium persulfate, which is 100 to 150 times cheaper than traditional oxidants, enhances the reaction rate due to better dispersion of insoluble LFP. This lowers overall processing costs while maintaining high delithiation efficiency.

- Rapid and Controlled Pulsated Microwave Delithiation: The innovative pulsated microwave treatment shortens the delithiation process from several hours to just minutes. The pulsation prevents overheating and maintains the crystal integrity of LFP, ensuring consistent quality of recovered materials.

- High Lithium Recovery Yield with Reduced Processing Time: The technology achieves an exceptional lithium recovery rate of 97%-99%, reducing the required leaching time to as little as 20 to 30 seconds. This high yield combined with speed improves the overall throughput and economic viability of recycling.

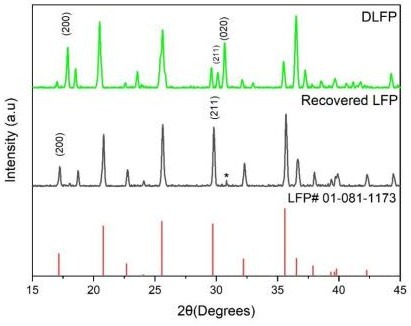

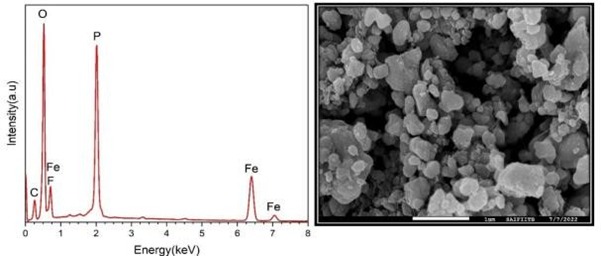

- Production of High-Purity Lithium Phosphate and Iron Phosphate Byproduct: The process yields lithium phosphate with minimal impurities without the need for additional heating or pH adjustments, thanks to selective precipitation. The iron phosphate byproduct retains the original crystal structure, making both products valuable for reuse.

- Energy-Efficient and Scalable for Industrial Application: By integrating ultrasonication and controlled microwave treatment, the process lowers energy consumption compared to conventional methods. The scalable nature of the process makes it suitable for industrial-level lithium-ion battery recycling, supporting sustainable resource management.

NA

The technology has been demonstrated and validated in lab environment.

4

This technology promotes sustainable recycling of lithium-ion batteries by efficiently recovering lithium, thereby reducing electronic waste and environmental pollution. By supporting a circular economy, it decreases reliance on raw lithium mining, conserving natural resources. The process lowers the cost of lithium recovery, making battery recycling more economically viable and accessible. Additionally, it contributes to cleaner energy storage solutions through material reuse and helps protect ecosystems and human health by minimizing hazardous waste from spent batteries.

- Lithium-ion battery recycling and refurbishment industry

- Battery manufacturing and materials recovery sectors

- Renewable energy storage and electric vehicle industries

- Environmental management and waste treatment sectors

- Chemical and materials engineering fields focused on sustainable processes

Geography of IP

Type of IP

202321042255

550410