This invention discloses an eco-friendly polymer foam composite comprising a reduced graphene oxide (rGO)-coated oxidized graphene framework (OGF) embedded within a polyurethane (PU) matrix. The OGF is synthesized from bagasse, a sugar industry biomass waste, offering a sustainable and low-cost precursor material. The composite foam exhibits super-oleophilic and hydrophobic properties, enabling efficient and selective oil absorption from oil–water mixtures. The fabrication process is simple, non-toxic, and scalable, involving dip-coating and thermal reduction steps. The resulting foam is lightweight, porous, mechanically resilient, and reusable across multiple cycles, making it particularly suitable for oil spill recovery and environmental remediation.

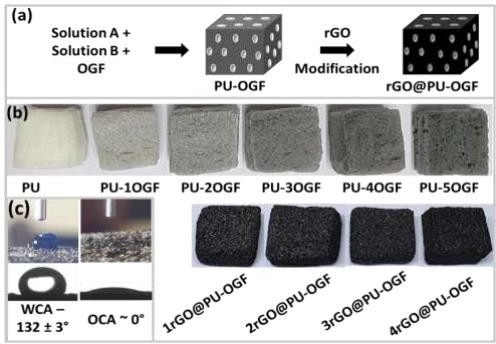

Figure (1a) Schematic presentation for synthesis of Graphome (rGO@PU-OGF) foam, (1b) As-syntehsized foams with variation in OGF and rGO amounts, (1c) Photograph of water droplet and motor oil droplet with contact angle on rGO@PU-OGF foam surface; (2) Depicts a Raman spectra of pristine PU foam, nanocomposite foam (PU-OGF), surface modified nanocomposite foam (rGO@PU-OGF)

Existing materials used for oil spill cleanup and oil-water separation are often costly, environmentally toxic, non-reusable, and limited in scalability. There is a critical need for a sustainable, cost-effective, and reusable material that can efficiently separate oil from water without releasing hazardous pollutants during synthesis or deployment.

- Eco-friendly Material: The technology incorporates an oxidized graphene framework (OGF) synthesized from sugar industry biomass waste (bagasse), supporting sustainable and renewable material sourcing.

- Simple and Scalable Fabrication: It employs a cost-effective, one-step dip-coating and thermal reduction process, suitable for industrial-scale production.

- Enhanced Oil Absorption: It demonstrates super-oleophilic and hydrophobic behavior, enabling selective and efficient oil uptake from oil-water mixtures.

- High Porosity and Reusability: It features an interconnected macro- and micro-porous structure, ensuring high absorption capacity and mechanical robustness over multiple reuse cycles.

- No Toxic Additives: It eliminates the use of hazardous chemicals commonly found in traditional foam production, reducing both environmental impact and health hazards.

- Multifunctional Performance: It is capable of absorbing a wide range of oils and organic solvents; suitable for oil spill cleanup, wastewater treatment, and other environmental remediation applications.

The prototype comprises a polyurethane foam integrated with an oxidized graphene framework (OGF) derived from bagasse biomass. This composite is subsequently dip-coated with a graphene oxide (GO) solution and thermally reduced to form a reduced graphene oxide (rGO) surface layer. Characterization has been performed using Raman spectroscopy, SEM, XRD, FTIR, XPS, contact angle measurements, and mechanical testing. The foam demonstrates high oil sorption capacity across a range of oils-including motor oil, vegetable oils, and organic solvents, while exhibiting super-oleophilic and hydrophobic behavior. It maintains structural integrity under compression and retains its absorption performance over multiple reuse cycles, indicating durability and suitability for real-world oil spill remediation.

The technology is at early Prototype development and/or validation in relevant environment stage.

5

This technology provides an environmentally responsible solution for mitigating oil pollution in aquatic environments by selectively absorbing oil using bio-waste-derived materials. By valorizing industrial biomass waste (bagasse), it promotes a circular economy and sustainable manufacturing. The absence of toxic chemical additives enhances environmental and human safety. Furthermore, its cost-effective, scalable fabrication supports widespread deployment, enabling cleaner water bodies, healthier ecosystems, and alignment with United Nations Sustainable Development Goals (SDGs).

- Environmental remediation: Oil spill cleanup and water purification

- Wastewater treatment and oily wastewater management

- Petrochemical and oil industries for spill management

- Marine and coastal protection agencies

- Industrial filtration and separation technologies

- Material science and advanced manufacturing sectors

Geography of IP

Type of IP

202221055324

507021