The present invention relates to polymer nanocomposites comprising nanocubons with uniform size and morphology, along with a process for their preparation. These nanocubons exhibit desirable dielectric properties, making them suitable as nanofillers for electrical insulation in electronic devices. Unlike conventional ceramic fillers, these nanocubons avoid drawbacks such as bulkiness, increased viscosity, and conductivity risks, thus offering enhanced compatibility and performance in applications requiring thermal regulation and dielectric strength.

Conventional ceramic nanofillers used in electronic and fluid systems enhance dielectric and thermal properties but face key drawbacks—bulkiness, poor dispersion, increased viscosity, and unintended electrical conductivity. There is a need for alternative nanofillers that offer high dielectric strength and insulation without these limitations, especially for applications like sensors, medical devices, and pulse conditioning systems.

- Dielectric Properties with Electrical Insulation: The nanocubons demonstrated strong dielectric behavior while maintaining electrical insulation due to the PPC (Poly (propylene carbonate)) matrix, overcoming the limitations of conventional ceramic fillers like high bulkiness, increased viscosity, and tunneling conductivity risks.

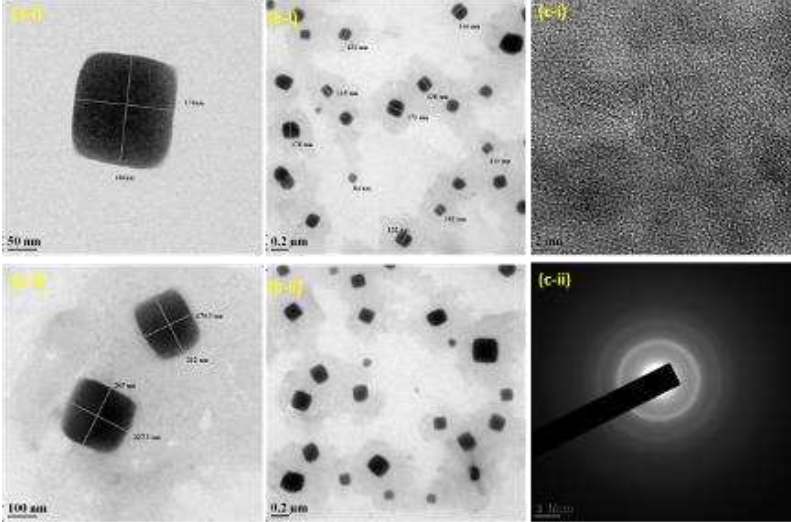

- No Aggregation or Settling: It has optimized particle size (100-250 nm) and uniform surface charge (zeta potential) that ensure long-term dispersion stability, solving problems such as nanoparticle settling or aggregation in nanofluids and composites.

- Semi-Crystalline Structure: The analysis revealed semi-crystalline morphology, offering a balance between strength and flexibility—ideal for medical, electronic and fluid insulation applications with strong dielectric behavior.

- Cost-Effective & Scalable Manufacturing: The Tetrahydrofuran (THF) synthesis process is simple, economical, and suitable for large-scale industrial production.

The process for preparing nanocubons involves dissolving polypropylene carbonate (PPC) in tetrahydrofuran (THF) to form a solution, which is then emulsified with polyvinyl alcohol (1–5% w/v) to create a stable emulsion. This emulsion undergoes sonication (40% amplitude, 5s on/2s off pulses for 10 minutes) to ensure uniform particle distribution. The solvent is then evaporated, and nanocubons are isolated via centrifugation. The resulting nanocubons typically range in size from 100 to 250 nm.

Currently at TRL 3 – proof of concept stage, with further development underway.

3

The development of PPC-based Nanocubons nanofillers can significantly enhance the performance and miniaturization of electronic, biomedical, and energy storage devices.

- Electronics

- Biomedical devices

- Sensor technology

- Nanotechnology

- Packaging industry

- Oil & Fluid technology

Geography of IP

Type of IP

202121007979

434460