This invention introduces a heat-treatment-based process that produces Sn-Bi alloy anodes with uniformly distributed Bi precipitates, significantly improving their electrochemical performance in Na-ion batteries. The optimized Sn:Bi (70:30) alloy shows improved cycling stability, rate capability, and structural strength, making it a scalable and sustainable solution for next-gen energy storage.

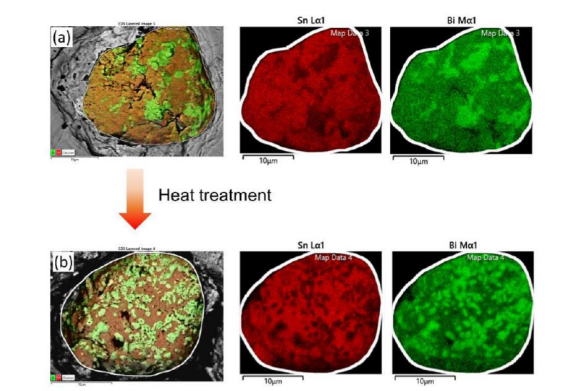

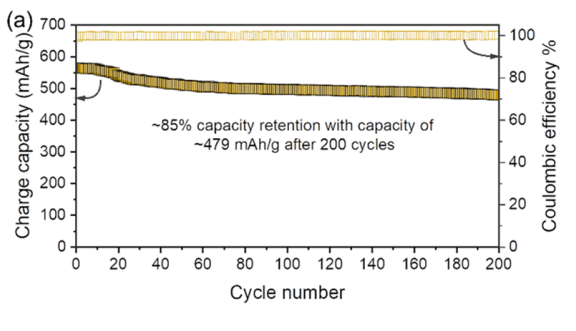

Figure (1) Illustrates Backscattered SEM images and corresponding elemental maps 10 (via EDS) of (a) ball milled, (b) heat treated Sn-Bi samples, illustrating the presence and distribution of Sn (in red) and Bi (in green); (2) Electrochemical cycling performance of Sn-Bi alloy in Na ‘half’ cells as Na-ion battery anodes at current density equivalent to 1C rate (a) Cycling stability, showing the variation in dissociation capacity with galvanostatic cycle number, and coulombic efficiency (CE) over 200 cycles at 1C for solution heat treated Sn-Bi alloy material.

Tin (Sn) is a high-capacity anode material for sodium-ion (Na-ion) batteries, but it suffers from severe volume expansion and mechanical degradation during cycling, resulting in capacity fade. Ball-milled Sn-Bi alloys offer moderate improvement, but poor Bi distribution limits their performance.

- Heat-Assisted Phase Control: The solution's heat treatment and aging allows uniform Bi precipitation in Sn, overcoming the poor phase distribution and coarse microstructure length scale in ball-milled samples.

- Improved Na-ion Transport: Even Bi distribution enhances sodium-ion diffusion and electrode reaction kinetics.

- Superior Performance: The treated alloy shows better capacity retention and high-rate performance than untreated samples.

- Eco-Friendly and Scalable Process: The method uses water-based slurry and mild heat, making it safe and easy to scale.

- Mechanical Durability: Fine Bi precipitates strengthen the alloy, improving its hardness and cycling stability.

Prototype electrodes were fabricated using a doctor blade method on Cu foil, followed by calendaring and punching. Electrochemical half-cells were assembled to validate performance against industry benchmarks.

4

The invention offers a low-cost, scalable, and eco-friendly method for developing next-generation Na-ion battery anodes. This supports the shift from lithium-based systems to more sustainable, sodium-based alternatives—critical for affordable energy storage in rural electrification, renewable energy grids, and electric mobility.

- Battery Manufacturing: For advanced Na-ion battery anode production

- Renewable Energy Storage: Suitable for storing solar and wind energy

- Electric Vehicles: Supports sustainable and efficient EV battery systems

- Consumer Electronics: Powers compact, high-performance devices

- Grid-Scale Energy Systems: Enables large-scale, long-duration energy storage

Geography of IP

Type of IP

202421008781

554945