This invention presents a novel, patient-specific 3D printed porous gel composite scaffold developed using a cryogenic extrusion-based method. It combines gelatin, carboxymethyl chitin (CMC), and hydroxyapatite (HA) to create biocompatible, biodegradable, and osteoconductive scaffolds. The technology enables multiscale control over scaffold structure-customized outer shape, gradient macro-architecture, and sub-micron porosity-without relying on synthetic growth factors. The use of programmable G-code allows creation of graded porosity in multiple directions, mimicking natural bone’s complexity.

Current bone graft methods-autografts, allografts, and synthetic substitutes-suffer limitations like donor site morbidity, immune rejection, disease transfer, and poor integration. There is a pressing need for a customizable, biocompatible scaffold that mimics natural bone morphology, supports cell growth, and is applicable to irregular defects.

- Hierarchical Morphology Control: The scaffold design allows control over the outer shape, internal pore structure, and surface roughness, closely mimicking natural bone architecture.

- Gradient Porosity via Python-Coded G-Code: Custom Python-generated G-code enables gradient porosity in multiple directions, replicating the natural transition from dense to porous bone.

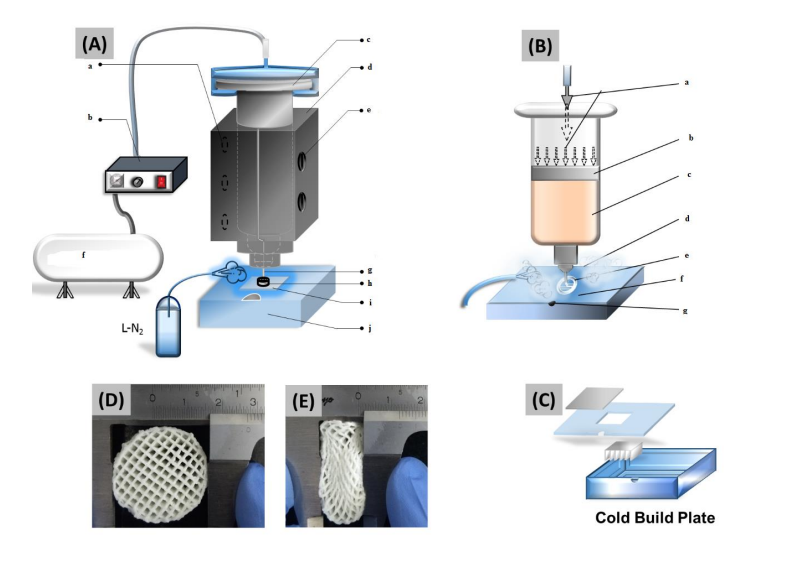

- Cryogenic Gel Extrusion Printing: The gel is printed onto a cold surface in a nitrogen-cooled environment, which instantly freezes it and preserves structural integrity.

- Material Composition Mimicking ECM: Natural polymers like gelatin and CMC simulate the extracellular matrix, while hydroxyapatite adds strength and supports bone cell growth.

- No Heat-Based Post Processing: Instead of using heat, lyophilization is employed to create micro-porosity and maintain the scaffold’s bioactivity.

The system consists of a custom-modified commercial 3D printer fitted with a CAD-designed aluminum block heater and syringe holder, cryogenic cooling unit, and Python-generated G-code printing algorithm. Scaffolds up to 27 mm diameter × 10 mm height were successfully fabricated and tested.

The technology is currently undergoing preclinical trials.

4

This scaffold platform provides a cost-effective, scalable, and customizable bone graft alternative that eliminates need for secondary surgical sites and reduces healing time. It improves access to personalized treatment in orthopedics and dentistry, especially in resource-constrained settings.

- Orthopedics: Treatment of complex and irregular bone defects

- Craniofacial Surgery: Personalized reconstruction of maxillofacial structures

- Dental Implants: Alveolar bone grafting in periodontics and prosthodontics

- Regenerative Medicine: Scaffold-based tissue regeneration platforms

- Medical Device Manufacturing: Biofabrication of implantable scaffolds

- 3D Bioprinting Industry: Customizable, patient-specific scaffold production

Geography of IP

Type of IP

201721037191

382552