The method comprises the steps of (a) providing a substrate, (b) preparing a scratch resistant coating composition comprising an acrylic-silane polymeric coating, a first hydrophilic silica, a second hydrophilic silica and a pigment dispersing agent, (c) preparing a hydrophobic coating composition, comprising an acrylic-silane polymeric coating, an hydrophobic additive flouroemulsion, a hydrophilic silica and a pigment dispersing agent, (d) preparing an antiglare, anti-fog coating composition prepared from a sol-gel, comprising a precursor solution, a solvent, an aqueous acid solution, a cross linking agent, an acid catalyst; and a silicone-based wetting additive, (e) applying a layer having three coating compositions prepared from step (b), (c) and (d) to at least one side of the substrate, and (f) drying the layer applied in step (e) and (g) curing the layer.

Existing surface coatings usually offer only one function – such as scratch resistance, hydrophobicity, or anti-fogging-and rely on expensive methods such as vacuum deposition, making them impractical for large-scale use. There is a need for a cost-effective, multifunctional, and optically clear coating that combines scratch resistance, hydrophobicity, anti-glare, and anti-fogging – ideal for optical, automotive, architectural, and electronic applications, where clarity and durability are essential.

- Integrated Multi-layer System: The technology combines three specialized coatings – scratch-resistant, hydrophobic, and anti-fog/anti-glare-into a single, multi-layered structure. Each layer is tailored for a specific function and synergistically contributes to overall durability, optical clarity, and environmental resistance.

- Low-Temperature Processing: Unlike conventional coatings that require high-temperature vacuum deposition, this system cures at mild temperatures (70°C-120°C), significantly reducing energy costs and enabling compatibility with temperature-sensitive substrates like polycarbonate.

- Sol-Gel Tunability: The anti-fog/anti-glare layer is based on sol-gel chemistry using a controlled ratio of silane precursors (HDTMS, GPTMS, TEOS), allowing precise manipulation of surface energy, porosity, and optical transmission. This makes the coating adaptable to various performance requirements.

- Customizable Additives: The system allows further enhancement through the optional inclusion of materials like Magnesium Fluoride (MgF₂) for improved anti-reflection, Titanium Oxide (TiO₂) for photocatalytic or UV-blocking properties, Silicon Dioxide (SiO₂) for mechanical stability, and fluoro-emulsions for increased hydrophobicity.

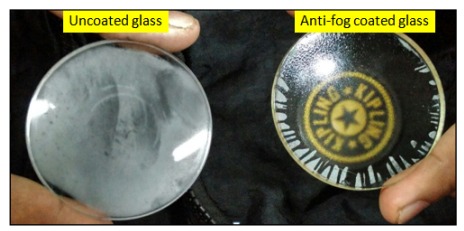

- High Functional Performance: Lab-scale testing shows excellent results across all metrics – a contact angle of ~109° demonstrates strong hydrophobicity; a significant reduction in reflectance across the visible spectrum confirms anti-glare effectiveness; and zero fog formation after exposure to extreme humidity and freezing conditions confirms robust anti-fogging behavior.

- Scalable Application Methods: The coating compositions are compatible with multiple industrially viable deposition techniques including dip-coating, spin-coating, and spray-coating. This ensures ease of adoption in various manufacturing setups without the need for specialized equipment.

Three functional coating prototypes have been successfully developed and demonstrated:

- A scratch-resistant coating using AEROSIL 300, R972, and BYK Terra U

- A hydrophobic coating incorporating FEE2000 fluoro-emulsion and AEROSIL R8200

- An anti-fog, anti-glare sol-gel coating formulated from a 1:1:3 ratio of HDTMS, GPTMS, and TEOS, processed with acetic acid, HMMM, and p-TSA, with optional nanoparticle enhancements.

These coatings were applied to polycarbonate and glass substrates using spin coating and tested under laboratory-scale conditions.

Anti-Glare, Anti scratch is the requirement of a good quality spectacle as it gives long life to your spectacle and imparts safety while driving.

7

The proposed multifunctional coating enhances visual clarity and safety in everyday and critical applications such as eyewear, helmets, windshields, and medical face shields by reducing glare and preventing fogging. It improves energy efficiency in solar panels and smart windows through better light transmission and offers a cost-effective alternative to expensive vacuum-based coatings. By increasing durability and surface protection, it helps reduce the frequency of product replacement. This technology also has significant benefits in healthcare and defense, where clear visibility is essential for performance and safety.

- Optics and Ophthalmology – Lenses, goggles, face shields

- Automotive and Transportation – Windshields, mirrors

- Consumer Electronics – Screens, camera lenses

- Renewable Energy – Solar panels

- Construction and Architecture – Anti-reflective, fog-resistant windows

- Healthcare – Protective eyewear, medical lenses

Geography of IP

Type of IP

201721011814

407897