A new electric motor design blends small permanent magnets with traditional copper windings in a clever, fully mixed layout in the rotor. By keeping the two magnetic sources completely separate yet working together, the motor stays compact, runs more efficiently, and can safely reach higher speeds and overloaded torques without risking damage to its magnets. All key ideas have been proven through detailed computer models and simulations.

Today’s electric motors, especially those in cars and high performance applications, rely heavily on rare-earth magnets that are expensive, hard to source, and can lose their strength if pushed too hard. At the same time, fully electrically-excited synchronous motors are reliable, low cost, sustainable, conveniently operable in over-load and field weakening zone but struggle to stay both powerful and efficient compared to rare earth magnet-based synchronous motors.

This creates a need for a motor design that uses fewer rare-earth materials, stays safe at high speeds and over-loading conditions, and remains efficient, compact and reliable.

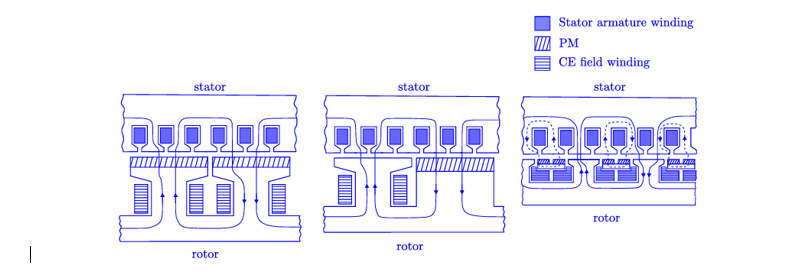

- True Magnetic Separation: Permanent magnets and copper windings are arranged so their magnetic flux path are decoupled, avoiding interference and boosting efficiency and power density.

- Compact and Powerful: By cleverly mixing small magnet segments with specially shaped windings, it packs more power into a smaller space without extra parts and geometrical variation along the shaft axis.

- Fully Hybridized Poles: Every pole combines two magnet segments and one winding segment, packing more power and controllability into less space.

- Built-In Field Weakening: Safe high-speed operation is achieved by simply dialing back the winding current with no extra demagnetizing steps needed.

- Segmented Rotor with Holding Rings: Non-magnetic spacers and rings keep the rotor parts firmly in place, simplifying assembly and reducing weight.

- Flexible Excitation Options: It can use brushes and slip rings or any brushless scheme including a brushless rotary-transformer to power the windings.

The motor exists as a fully developed computer model. Detailed 2D cross-sections and 3D drawings show exactly how each part fits together, and simulations confirm torque, voltage, and efficiency targets.

The design has reached proof-of-concept through extensive simulations. All key performance curves and mechanical layouts have been validated in software.

3

By cutting down on rare-earth magnets and using simpler, more compact rotor, this technology promises greener manufacturing and lower costs. It also makes electric vehicles and machines more efficient and durable, helping to reduce cost, energy consumption and environmental harm over the long term.

- Electric-vehicle propulsion

- Industrial-machine drives

- Wind-turbine generators

- Robotics and automation

- Compact household appliances

Geography of IP

Type of IP

202421038355

562835