A new electric motor design merges the best of permanent‐magnet and electrically‐excited machines into one “hybrid” rotor. Each pole on the spinning part holds both a strong magnet and two electrically-excited pole pieces, with their magnetic paths kept entirely separate. This lets the motor stay efficient at normal speeds and safely weaken its field at high speeds without risking demagnetizing the magnets. The design also cuts down on rare‐earth materials and offers flexible control methods either with simple brushes or a fully brushless setup.

Electric motors are used in almost everywhere for motor control applications such as in vehicles, automations, and power systems. Most of the high-efficiency motors use rare-earth magnets, which are expensive, hard to source, and harmful to the environment. Conventional permanent synchronous motor struggles to be safe against magnet demagnetization during over-load and high-speed operations, making the motors less reliable. There’s a strong need for motors that are reliable, cost-effective, and environmentally friendly along with efficient and power dense especially for electric vehicles, renewable energy systems and high-performance applications.

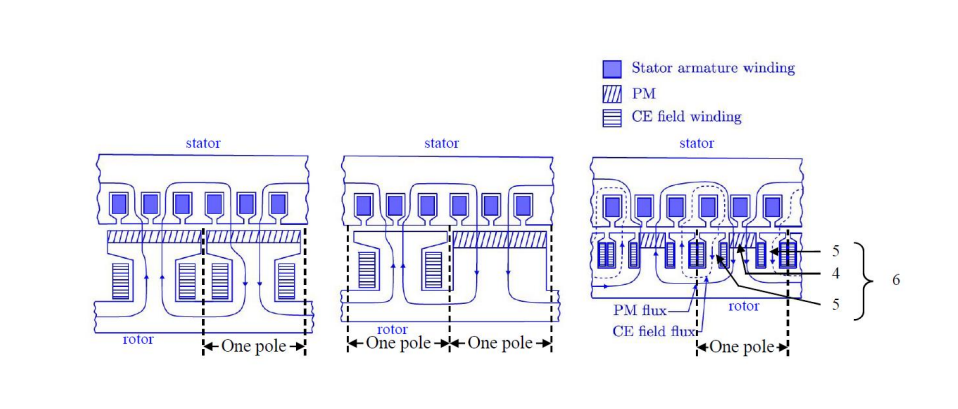

- Fully Hybridized Rotor Poles: This design integrates one permanent magnet sub pole piece between two electromagnetic sub pole-pieces in each complete rotor pole. The configuration allows both the permanent magnet and the rotor electrical coils to contribute jointly to torque generation, maximizing magnetic utilization and overall performance.

- Truly Parallel Flux Paths: The magnetic flux from the rotor coils and the permanent magnets travels through entirely separate paths. By preventing magnetic interference between the two sources, this design significantly improves magnetic efficiency and power density and minimizes losses.

- Segmented Magnetic Core: The rotor uses non-magnetic barriers to divide the magnetic circuits into distinct zones for permanent magnet and electromagnet. This segmentation keeps the magnetic fields concentric and stable, resulting in smoother torque output, better control, and an improved power factor.

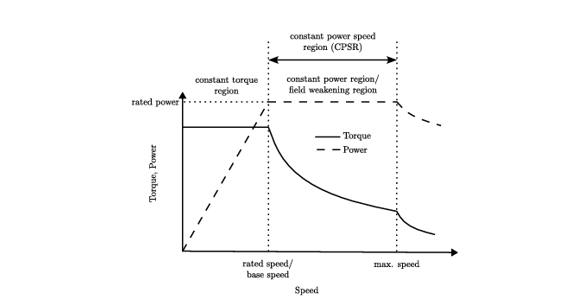

- Wide Speed Range: At higher speeds, the machine weakens the magnetic field using only coil current, without stressing or demagnetizing the permanent magnets. This allows the motor to maintain high performance over a broad range of operating speeds.

- Reduced Rare-Earth Usage: Because the coils assist the magnets, the design requires much smaller permanent magnets. This reduction lowers manufacturing costs and minimizes reliance on rare-earth materials, which are expensive and environmentally taxing to produce.

- Dual Excitation Options: The rotor can receive excitation current through either traditional brush/slip-ring assemblies or a more advanced, brushless method. Options include using auxiliary windings or a rotatory transformer, giving flexibility in design and maintenance.

The design has been fully fleshed out in detailed CAD drawings and tested through electromagnetic simulations. Virtual performance curves (torque vs. speed, voltage waveforms) confirm the concept.

The technology stands at a proof-of-concept stage. All key dimensions, materials, and control schemes are defined on paper and validated in software.

3

By slashing reliance on rare‐earth magnets, this motor reduces mining-related pollution and price volatility. Its high efficiency and wide operation range support greener transportation (electric cars, e-bikes) and cleaner power generation (wind turbines, hydro). Lower costs and longer service life make advanced electric drives accessible to more industries and communities.

- Electric vehicle traction motors

- Wind and hydro generator drives

- Industrial automation and robotics

- Aerospace propulsion systems

- Marine and off-road machinery

- Home appliances and HVAC compressors

Geography of IP

Type of IP

202421046326

561016