A new motor rotor design places a small amount of expensive rare-earth magnet together with a larger ferrite magnet in a “T” shape inside each rotor slot. This clever mix cuts material costs, boosts torque, lowers vibration, and keeps energy losses and heat down. It has been simulated with an 8-pole rotor and matches the efficiency of high-end motors at a fraction of the cost.

Electric motors used in vehicles, pumps, and drones often depend heavily on expensive rare earth materials to achieve good performance. These materials increase the cost of the motor significantly. On the other hand, motors using cheaper materials like ferrite magnets tend to be less efficient and have more power loss. There is a need for a motor design that balances cost, efficiency, and performance.

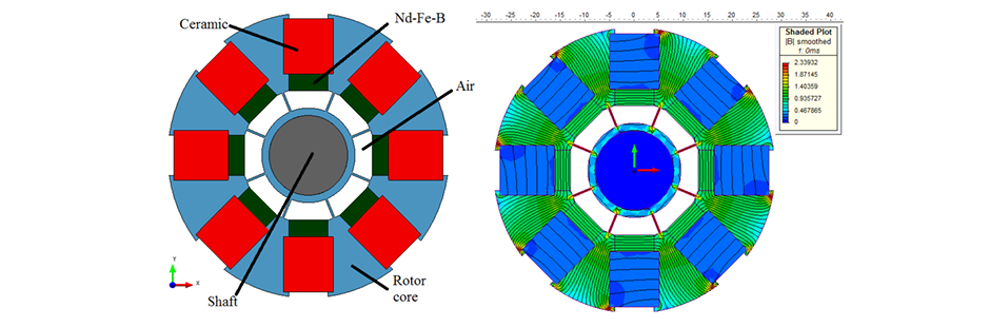

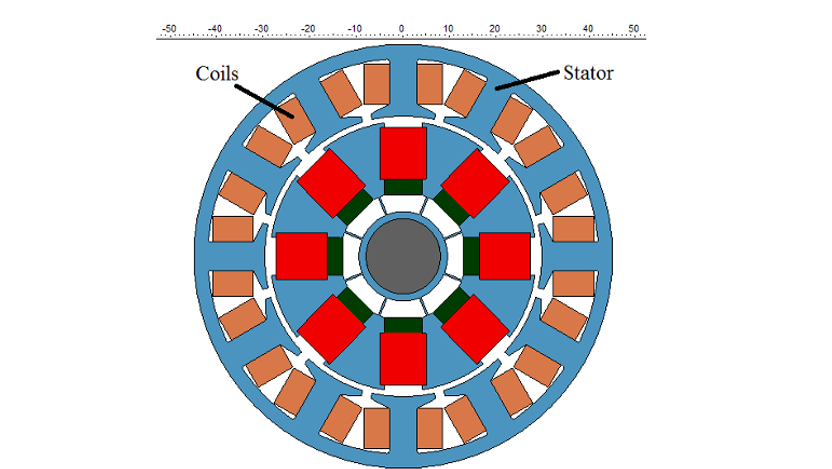

- Hybrid T-Spoke Magnet Layout: This product combines a small rare-earth magnet with a larger ferrite magnet in each rotor slot. The “T” shape directs magnetic flux efficiently, increasing output torque and minimizing ripple.

- Higher Torque with Less Rare-Earth Material: It achieves 6.3 Nm vs. 5.75 Nm in a standard rotor while using ~60% less rare-earth material. Saves on expensive metals without compromising on the output power.

- Reduced Torque Ripple and Vibration: Torque ripple drops from 30% to 16.5%, resulting in smooth rotation and lower mechanical stress ideal for precision applications like drones and pumps.

- Lower Copper Requirement and Heat Generation: It needs less copper winding to achieve similar performance, reducing copper loss and winding temperature for longer motor life.

- Cost-Effective Energy Efficiency: It delivers ~93% efficiency on par with rare-earth-only designs while cutting total material cost by about 30%.

An eight-pole BLDC motor was simulated with the T-spoke rotor. Detailed dimensions, magnet volumes, and air-gap clearances were set to match standard motor frames. Flux lines were mapped in simulation, and torque and efficiency were measured to verify performance gains over conventional designs.

The current technology is at the proof-of-concept stage.

3

This new motor technology cuts down the use of costly, imported rare-earth materials, which are usually hard to source and expensive. By making motors more affordable and easier to build within the country, it supports the Make-in-India movement and boosts local manufacturing. As a result, electric vehicles (EVs) can become cheaper and more accessible to the public, especially in rural areas where cost is a big factor.

Similarly, efficient motors can be used in clean water pumps for agriculture and daily use, as well as in low-cost home appliances like fans, refrigerators, and washing machines. Since these motors waste less energy during operation, they help reduce electricity consumption, which means lower electricity bills for users and less strain on the power grid.

On a larger scale, this also leads to fewer carbon emissions, helping industries and communities take a step toward a greener, more sustainable future. In short, this innovation makes advanced technology affordable, practical, and environment-friendly for everyday use across India.

- Electric vehicles and e-bikes

- Drone propulsion systems

- Bore-well and submersible pumps

- Industrial fans and blowers

- Robotics and automation equipment

- Renewable energy generators

- Household and commercial appliances

Geography of IP

Type of IP

202021002864

486646