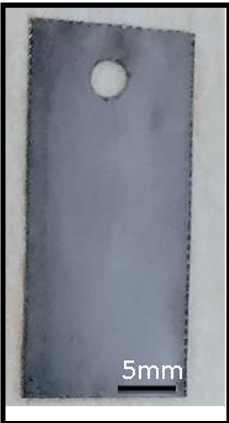

This innovation gives an electroless coating method for molybdenum-based alloys, specifically Titanium-Zirconium-Molybdenum (TZM) alloy, enabling the deposition of an oxidation and high temperature resistant Ni-B coating. The process involves use of catalytically active metal deposited on the surface of TZM substrate, which facilitates electroless deposition of high temperature resistant Ni-B coating thereby significantly cutting down on the cost of deposition of an oxidation resistant coating. The resulting coating demonstrates excellent thermal stability, withstanding 700°C in an oxidizing atmosphere for up to one hour without defects or cracking.

Existing methods to improve TZM alloy’s high-temperature oxidation resistance are costly or limited by coating thickness and substrate compatibility. Electroless Ni-B coatings require expensive palladium activation, making them impractical for industrial use.

There is a need for manufacturing cost-effective, high temperature and oxidation resistant coating methods on Titanium-Zirconium-Molybdenum alloy which also eliminates the above limitations.

- Electroless Coating: This process enables electroless high temperature and oxidation resistant Ni-B coating on TZM alloy capable of withstanding 700°C in an oxidizing atmosphere.

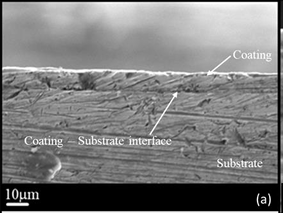

- Coating Thickness & Structure: The Ni-B coating forms a uniform, nodular, defect-free layer with thickness ranging from 5–20 µm; typically, around 12 µm revealed by tests (FESEM and XRD).

- Post-Heat Treatment Behavior: After heating at 700°C for 1 hour, the coating remains intact and free of cracks or oxides (MoO2 and MoO3).

- Cost & Process Efficiency: The method reduces cost by avoiding PdCl₂ and using less expensive catalytic active metals like Aluminum, requires no excessive heat, and uses fresh baths to maintain coating integrity.

NA

4

This invention offers a cost-effective, eco-friendly method to enhance TZM alloy's high-temperature performance, benefiting industries like aerospace and energy. By eliminating toxic, expensive palladium, it promotes safer, more sustainable manufacturing and supports advanced material development for critical applications.

- Aerospace and Defense

- Nuclear and Thermal Power

- Automotive

- Electronics and Semiconductors

- Tooling and Manufacturing

Geography of IP

Type of IP

202321063301

554069