This innovation relates to a method and system for hot gas micro forming of thin metallic sheets, specifically designed to produce miniature metal parts with high precision. An assembled system of tooling (design, selection of tools and different tools to be used in the method) and method for hot gas microforming at high temperature and pressure, without corrosion/oxidation of the foil material.

Conventional micro-scale metal forming methods are limited by low formability, high spring-back, poor surface finish, and low productivity due to room-temperature processing.

While hot gas forming addresses these challenges by hot forming there is a need for a controlled, non-corrosive hot gas forming process that also eliminates direct handling of hot foil to improve efficiency and safety.

- Oxidation and Corrosion Resistance: The foil is enclosed in a sealed environment with inert/vacuum atmosphere, effectively preventing oxidation and corrosion during high-temperature forming.

- No Direct Handling of Foils at High Temperatures: The foil is pre-assembled into the system at room temperature, eliminating manual handling during the heating process for improved safety and accuracy.

- Self-Generating Gas Pressure: The system uses internal vaporization of a non-corrosive, non-reactive liquid (e.g. demineralized water) to generate gas pressure, removing the need for external gas supplies.

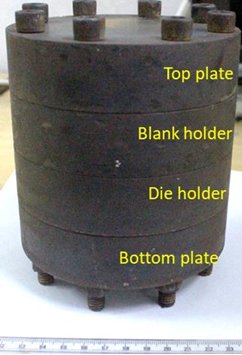

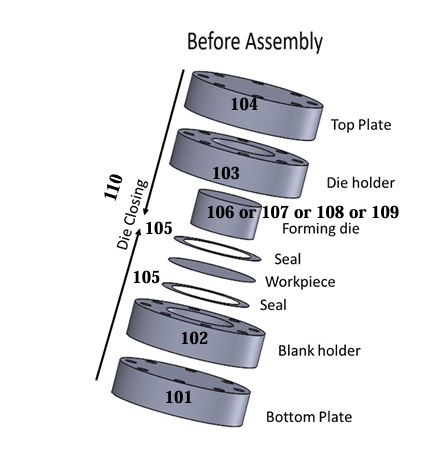

The prototype consists of a top plate, blank holder filled with non-corrosive and non-reactive liquid, metallic seal, thin foil workpiece, die holder with interchangeable forming dies, and a bottom plate. All components are aligned and bolted together to form a sealed system. This assembly is then heated in an inert or vacuum furnace to perform hot gas micro forming.

5

This technology boosts precision manufacturing in healthcare, electronics, and aerospace, enabling smaller, more reliable devices. It reduces waste and energy use through efficient forming and enhances safety by eliminating direct handling of heated metal foils.

- Microelectronics

- Medical device manufacturing

- Aerospace industry

- Automotive industry

- Manufacturing industry (Micro manufacturing)

Geography of IP

Type of IP

202221026792

548090