This invention relates in general to a process for the treatment of forging metal oxide scale waste. More specifically, it relates to a process for recycling or converting forging oxide waste into finished articles and thereby getting raw materials to make new metallic products and also avoiding expenditure on scrap disposal.

There is a need for a cost effective, efficient methods and systems processing metal oxide scale from a forge shop floor waste.

- Use of Waste as Raw Materials for Recycling: Plastic and paper from waste plastic and waste paper are used as raw materials required in binder formulation. There is also no addition of virgin metal.

- Simple and Economical Process: A high purity metal and highly valuable metal is obtained from the process.

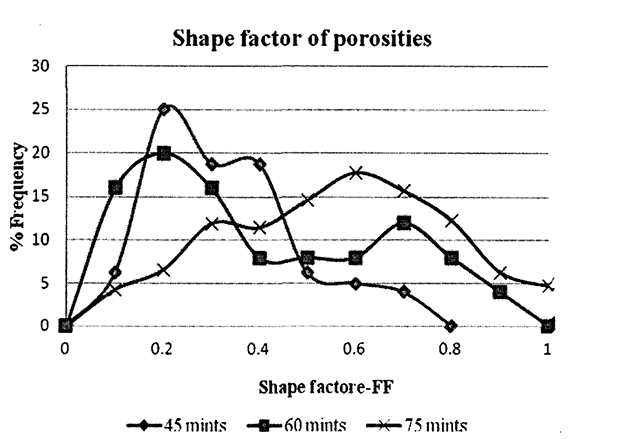

- Different Properties of Output Metal: The porosity and density of the metal can be varied according to the process.

The disclosed recycling method for forging oxide scale waste involves several systematic steps to convert waste into usable metal components. Initially, the forging oxide scale waste is crushed to prepare it for ball milling. A dry ball milling process follows, conducted without any wetting agents for 75 minutes to reduce the particle size. This is succeeded by a wet ball milling step to further reduce particle size and control the heat generated during milling. The milled oxide waste is then mixed with a reducing agent, followed by the addition of plastic, stearic acid, and paraffin wax in an 80:20 ratio to form a moldable mixture. This mixture is shaped into a green compact using a metal injection moulding machine. The moulded green compact undergoes a debinding process to remove the binders, followed by drying. It is then subjected to thermal debinding in a vacuum furnace to extract remaining binders and create a porous structure. Finally, the porous green compact is sintered and deoxidized in a vacuum using a reducing agent at temperatures exceeding 1000°C, resulting in a solid, recycled metal product ready for use.

5

This invention enables the recycling of forging metal oxide waste into usable metal products, reducing industrial waste and environmental pollution. It lowers the cost and need for raw material extraction. Additionally, it minimizes scrap disposal expenses, promoting sustainable manufacturing.

- Metal forging

- Steel and iron manufacturing

- Automotive

- Aerospace

- Heavy machinery

- Construction equipment

- Recycling and waste management

- Metallurgical engineering

Geography of IP

Type of IP

2026/MUM/2012

365627