This invention relates to polyolefin-grafted silsesquioxane nanosheets, a novel class of nanocomposites with covalently bonded polyolefin chains (such as polyethylene or polycyclooctene) on a 2D sheet-like inorganic framework. These hybrid materials combine the chemical robustness of silsesquioxanes with the desirable properties of polyolefins, offering new possibilities in composite materials design and adhesion science.

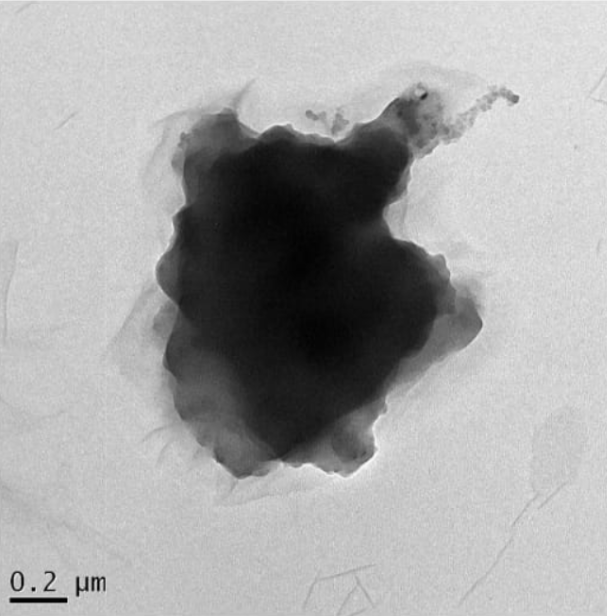

Figure (1) This transmission electron microscopy (TEM) image shows the morphology of the synthesized silsesquioxane-based nanomaterial, featuring a dense central region with extended polymer growth. (2) This schematic shows cohesive failure of PE-sil on metal, indicating strong adhesion enabled by grafted silsesquioxane and polyethylene chains.

Polyolefins like polyethylene and polypropylene are widely used polymers known for their durability, low cost, and chemical resistance. However, reinforcing these materials with sheet-like nanofillers (such as clays or graphene) has remained a challenge due to their apolar nature. These fillers often aggregate or fail to disperse uniformly in polyolefin matrices, leading to poor mechanical properties and unreliable performance.

Conventional approaches using physical adsorption of surfactant-based systems have limited stability and effectiveness, creating a need for a robust method to chemically bind polyolefins to 2D nanostructures.

- Covalent Grafting on Nanosheets: The invention demonstrates a novel method to covalently graft polyolefin chains onto the surface of silsesquioxane nanosheets, overcoming the typical incompatibility between nonpolar polymers and polar fillers. This enables the formation of nanocomposites with improved structural integrity and dispersion.

- Two-Step Synthesis Approach: The process involves surface-initiated ring-opening metathesis polymerization (SI-ROMP) of cyclooctene on the silsesquioxane surface, followed by catalytic hydrogenation. This sequence converts the unsaturated polymer into polyethylene, firmly tethered to the nanosheet surface.

- Enhanced Material Properties: The grafted nanosheets exhibit improved crystallinity, dispersion in polyolefin matrices, and enhanced thermal and mechanical behavior. These features make them suitable for integration into high-performance polymer systems.

- Significant Adhesion Improvement: Polyethylene-grafted silsesquioxane sheets show 2 to 100 times stronger adhesion to substrates such as glass, metal, and Mylar® compared to standard polyethylene. This uncommon adhesive behavior expands the potential for applications in coatings, adhesives, and laminates.

- Versatility and Compatibility: The platform is compatible with a range of polyolefins and can be extended to other cyclic olefins. This makes the method highly adaptable for industrial polymer blending and composite manufacturing.

The prototype consists of a nanosheet-based composite material built from silsesquioxane sheets grafted with polyolefin chains. The core structural unit is a layered polysilsesquioxane containing vinyl functional groups, which serve as anchoring points for polymer grafting.

The surface of these nanosheets is first functionalized with Grubbs’ 2nd generation catalyst, enabling surface-initiated ring-opening metathesis polymerization (SI-ROMP) of cis-cyclooctene. This results in polycyclooctene chains being grown directly from the sheet surface. In the second step, the unsaturated polymer chains are hydrogenated using p-toluenesulfonyl hydrazide (TSH) in refluxing xylene, converting them into polyethylene-grafted silsesquioxane nanosheets.

The final prototype material consists of thin, sheet-like silsesquioxane structures with densely grafted polyethylene chains on their surfaces. These grafted nanosheets are lightweight, free-standing powders that can be dispersed in polymer matrices.

The technology has been validated at laboratory scale. The composite material has been synthesized and characterized using advanced techniques such as NMR, SEM, TEM, XRD, TGA, SAXS, and DSC. Lap shear and pull-off adhesion tests have confirmed superior bonding performance. This novel material has unprecedented properties.

3

Apolar polymer coatings that adhere to metals could have use in coatings for hydrogen storage tanks. These materials represent a new class of hydrophobic adhesives that can bond to a wide variety of substrates.

- Polymer nanocomposites

- Industrial adhesives and sealants

- Aerospace and automotive materials

- Advanced functional coatings and barriers

Geography of IP

Type of IP

202221012159

550069