The present invention relates to a premix burner designed for the efficient combustion of low calorific value (CV) gaseous fuels. The burner comprises a vertical combustor body that includes a cylindrical section at the top and an inverted conical section at the bottom, separated by a horizontal circular plate. This plate is fitted with multiple swirl vanes for gaseous fuel input and dome-shaped swirl vanes for secondary air input. These vanes facilitate thorough mixing of air and fuel while generating a strong swirling motion within the combustor, promoting stable combustion. At the upper end of the combustor, a second plate is provided, incorporating a bluff body that guides the air fuel mixture toward the combustion zone and aids in flame stabilization. Additionally, a pilot flame holder is integrated into the design, utilizing the same premixed air-fuel mixture to provide a continuous ignition source, thereby eliminating the need for external ignition systems.

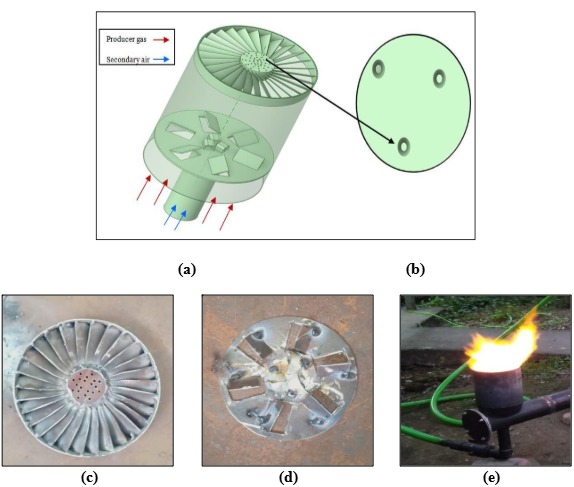

Figure (1) 3D view of the burner with all parts assembled; (2a) 3D model of premix burner, (2b) Mini divergent cone punch hole for stable pilot flame, (2c) Photographic view of bluff body, (2d) Photographic view of dual slit swirler (swirl vane), (2e) Photographic view of producer gas fired premix burner

Combusting low calorific value (CV) gases like producer gas is challenging due to low energy density, impurities, and instability. Conventional burners struggle with emissions, fluctuating flow, and need auxiliary fuels. To address this, a specialized low emission premix burner is needed capable of stable combustion, efficient mixing, built-in ignition, and clean operation across varying conditions without the need for external cleaning or support fuels.

- Efficient Premix Burner Design: A vertical combustor body featuring cylindrical and inverted conical sections, integrated with two specialized plates-a swirler plate (equipped with swirl vanes and dome-shaped swirl vanes) and a flame stabilization plate (housing a bluff body and pilot flame holder)-ensures optimal premixing and stable combustion of low-CV gaseous fuels.

- Advanced Swirling Mechanism: The swirl vanes induce a strong swirling flow inside the combustor, promoting thorough mixing of air and fuel, enhancing flame stability, reducing flame length, and improving overall thermal efficiency.

- Inbuilt Pilot Flame Holder: Continuous ignition is sustained using the same low-CV fuel, eliminating the need for external pilot flames or auxiliary fuel sources, thereby simplifying operations and reducing operational costs.

- Tar Destruction and Particulate Matter Management: High flame temperatures combined with sufficient residence time and swirling action ensure complete cracking of tar and effective settling of particulate matter, removing the need for external tar removal or gas cleaning equipment.

- Adjustable Secondary Air Supply: It enables precise control of the air-fuel ratio and flame temperature, supporting operation over a wide turndown ratio and enhancing burner stability across varying flow rates.

- High Thermal Efficiency & Low Emissions: It achieves flame temperatures above 800-degree centigrade with thermal efficiencies exceeding 50%, while maintaining particulate emissions (PM2.5 and PM10) well below regulatory limits such as CPCB standards.

- Scalable and Versatile: Compatible with various low-CV gaseous fuels and capable of operating efficiently across a broad range of flow rates, making it suitable for both small- and large-scale applications.

A prototype premix burner is developed for combusting low-CV gaseous fuel, such as producer gas from a downdraft gasifier. It consists of a vertical combustor body with a cylindrical top and inverted conical bottom separated by a swirl vane-integrated first plate. Six fuel swirl vanes (inclined at 32-degree) and three domed air swirl vanes induce strong mixing. A second plate features a 45-degree bluff body and a pilot flame holder using the same air-fuel mix for continuous ignition. The compact design promotes high flame temperatures, efficient combustion, and tar destruction without external cleaning units.

The burner is currently deployed in community kitchens at Ashram schools for cooking applications. With a Technology Readiness Level (TRL) of 9, it is ready for industrial deployment and is already in use in jaggery production and sand reclamation industries.

9

This research presents a low-CV burner for clean, high-temperature combustion (400-1200°C) of fuels like producer gas. With a wide Wobbe’s Index range, it ensures fuel flexibility, stable performance, and ultra-low emissions. Already deployed in community kitchens and industries, this TRL-9 technology supports clean energy adoption, better air quality, and reduced fossil fuel use. It has successfully enabled thermal industries to transition from fossil fuels to renewable energy while meeting their required thermal output.

- Power Generation: Gas engines or turbines fueled by producer gas or similar low-CV fuels

- Biomass Gasification Plants: Use with downdraft gasifiers for efficient producer gas utilization

- Waste-to-Energy Systems: Combustion of low-CV gases from waste treatment

- Environmental Technologies: Reducing particulate matter and tar in combustion units

Geography of IP

Type of IP

202321046472

548679