This invention presents a high-voltage, rechargeable zinc-ion battery based on a non-aqueous dual-ion electrolyte system. The battery features a zinc metal anode, an ethylene glycol-based electrolyte containing both Zn²⁺ and K⁺ ions, and a copper hexacyanoferrate (CuHCF) cathode, a Prussian blue analogue. The selective intercalation of K⁺ ions at the cathode enhances electrochemical stability, while zinc plating and stripping occur at the anode. This system eliminates dendritic growth, improves cycle life, and delivers consistent performance over extended use.

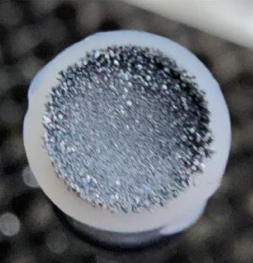

Figure (1) Zinc plating from 1 M ZnCl₂ + 1 M KCl in water shows a highly dendritic morphology after chronoamperometry at -0.5 V vs Zn wire reference for 300 seconds; (2) Zinc plating from 1 M ZnCl₂ + 1 M KCl in ethylene glycol shows a uniform, grainy morphology after chronoamperometry at -0.5 V vs Zn wire reference for 300 seconds; (3) Final pouch-type zinc-ion battery is sealed in aluminum laminate packaging for stability and storage

Zinc batteries are widely used due to their low cost, safety, and environmental friendliness. However, commercial zinc batteries are typically non-rechargeable. Attempts to develop rechargeable zinc-ion batteries have been hindered by several issues: dendritic zinc deposition leading to short circuits, parasitic side reactions like hydrogen evolution and passivation, and poor long-term stability of cathode materials. Traditional aqueous electrolytes fail to solve these problems, and most cathode materials degrade quickly with repeated zinc ion intercalation. There is a pressing need for a stable, high-voltage, dendrite-free, rechargeable zinc-ion battery system.

- Dual-ion System: The battery uses a unique combination of zinc (Zn²⁺) and potassium (K⁺) ions dissolved in ethylene glycol as the electrolyte. This dual-ion setup helps improve ion transport and stability during cycling. While Zn²⁺ handles charge transfer at the anode, the inclusion of K⁺ ions enhances the overall electrochemical performance, especially at the cathode.

- Selective Intercalation: During discharge, K⁺ ions preferentially insert themselves into the copper hexacyanoferrate (CuHCF) cathode structure. This selective intercalation prevents the structural damage typically caused by repeated Zn²⁺ insertion, helping the cathode retain its integrity over multiple charge-discharge cycles.

- Dendrite-free Zinc Plating: The use of ethylene glycol as the electrolyte medium plays a critical role in preventing the growth of zinc dendrites—needle-like structures that can cause short circuits. It also suppresses unwanted side reactions like hydrogen gas evolution, which are common in aqueous electrolytes. This results in a safer and more stable battery operation.

- Stable Cycling: The battery exhibits excellent cycling performance, maintaining a discharge capacity of approximately 50 mAh/g even after more than 150 cycles at a high rate. This demonstrates the system's ability to deliver consistent energy output and durability under fast charging and discharging conditions.

- Safe and Scalable: By avoiding flammable solvents and relying on non-aqueous, low-volatility ethylene glycol, the battery enhances user safety. Additionally, the use of affordable materials and straightforward assembly makes the technology scalable for larger applications, including energy storage systems.

A functional pouch cell prototype was successfully fabricated using a zinc foil anode and a copper hexacyanoferrate (CuHCF) cathode supported on titanium foil. The electrolyte consisted of a non-aqueous solution of 1 M ZnCl₂ and 1 M KCl dissolved in ethylene glycol, which served as the medium for both zinc and potassium ion transport. A filter paper separator was used to maintain ionic conduction while preventing short circuits.

The prototype was assembled in an inert atmosphere to avoid contamination from moisture or oxygen. Charge-discharge tests were conducted at various current densities, with a primary focus on performance at a 2C rate. The battery demonstrated a stable discharge capacity of 50 mAh/g and good coulombic efficiency over more than 150 cycles. Cyclic voltammetry confirmed the reversible redox activity of the CuHCF cathode, while post-cycling analysis indicated minimal structural degradation.

The use of ethylene glycol enabled smooth zinc plating and stripping without dendrite formation, as confirmed by visual and electrochemical inspection. The compact design and use of cost-effective materials make this prototype a strong candidate for further optimization and scaling.

A functional laboratory prototype has been developed and tested successfully. The battery system has demonstrated stable performance in initial cycling trials. The technology is currently at the proof-of-concept stage and is ready for further validation, optimization, and potential scale-up through academic or industrial collaboration. Work is currently ongoing to improve packaging, increase cyclability (number of cycles), and enhance the battery’s overall capacity.

4

This battery system offers a safer, more sustainable alternative to lithium-ion batteries, particularly for stationary energy storage, portable electronics, and grid backup applications. Its use of abundant, non-toxic materials and dendrite-free operation enhances safety and cost-efficiency. It also opens pathways for rechargeable systems using other metal anodes like aluminum or magnesium.

- Stationary energy storage systems

- Household and industrial power backup

- Portable electronics

- Emerging non-lithium battery industries

- Research in next-gen rechargeable metal batteries

Geography of IP

Type of IP

202321012312

551806