The patented technology introduces a composite membrane designed for efficient oil-water separation. This membrane incorporates a nanohybrid of carbon nanomaterials within a polymer matrix, significantly enhancing hydrophilicity, mechanical strength, thermal stability, and oil separation performance. It offers a novel solution to industrial challenges of managing oily wastewater, particularly from sectors like the oil, gas, and petrochemical industries

Oily wastewater poses severe environmental risks, particularly with the expansion of industrial activities. Traditional polymeric membranes used for oil-water separation suffer from hydrophobicity, leading to high fouling and reduced efficacy and lifespan. This invention addresses the need for high oil removal efficiency, permeate flux, and antifouling membranes.

- Innovative Material Composition: The use of a synergistic combination of carbon nanomaterials, e.g., graphene oxide and carboxylated carbon nanotubes, enhances the overall performance of the membranes beyond traditional materials, offering improved separation metrics and longevity.

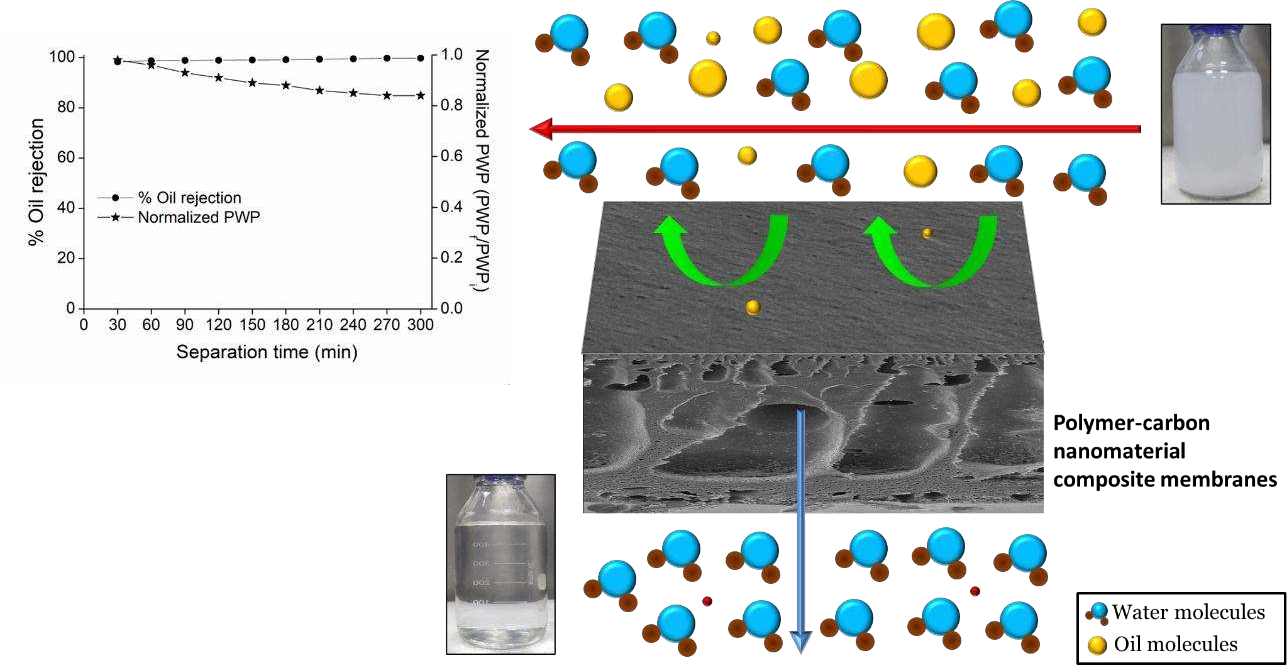

- Enhanced Hydrophilicity and Fouling Resistance: Incorporates a nanohybrid of carbon nanomaterials, reducing the water contact angle to 51.4°, which improves the hydrophilicity and enhances fouling resistance, demonstrated by high flux recovery ratio (>90%).

- Superior Mechanical and Thermal Properties: Possess mechanical strength with Young’s modulus up to 600 MPa and thermal stability with an onset degradation temperature over 500 °C, ensuring durability and robust performance under industrial conditions.

- High Efficiency in Oil-Water Separation: Achieves oil rejection rates of more than 98.5% and demonstrates a high-water permeation flux over 500 mL/m2/h/mmHg, indicating efficient separation and throughput.

The prototype of the composite membrane demonstrates a water permeation flux ranging from 100 to 600 mL/m2/h/mmHg, mechanical strength with Young’s modulus values between 200 to 600 MPa, and improved hydrophilicity with water contact angles decreasing to as low as 51.4°. These properties highlight the prototype’s robust performance in oil-water separation, tailored for high efficiency and durability in industrial applications.

The current technology has reached the prototype stage, showing promising laboratory results in oil-water separation. The prototypes exhibit improved hydrophilicity, mechanical strength, and high fouling resistance, indicating potential for industrial applications.

5

This technology stands to significantly mitigate environmental hazards associated with industrial wastes, offering a sustainable, efficient solution to oil-water separation challenges. It aligns with global efforts towards environmental protection and resource management, potentially reducing the ecological footprint of numerous industries.

Oil and Gas Industries, Petrochemicals, Food Processing Industry, Manufacturing Facilities

- Oil and Gas Industry: For treating wastewater generated from drilling and production operations, helping to meet environmental regulations and reduce water pollution.

- Petrochemicals: In the processing and manufacturing sectors, where oily wastewater is a common byproduct, ensuring cleaner discharge and recycling of process water.

- Food Processing Industry: Useful in facilities where large amounts of oily wastewater are generated, such as in the production of oils, dairy products, and meat processing.

- Manufacturing Facilities: Such as automotive, textile, and machinery industries, where emulsified oils in wastewater can be effectively separated, allowing for water reuse and waste reduction.

- Industrial Wastewater Treatment: Ideal for sectors like oil, gas, and petrochemicals which generate high volumes of oily wastewater.

- Environmental Management: Useful in ecological conservation efforts by reducing the pollutant load discharged into natural water bodies.

Geography of IP

Type of IP

201821045963

398654