This innovative process provides a method and apparatus for removing polymer components from a powder-polymer mixture. The method involves immersing parts of the powder-polymer mixture in a solvent within a heated ultrasonic bath. Ultrasonic excitation is applied to the immersed parts, intensifying the dissolution of the powder-polymer in the solvent, thereby accelerating the removal of polymer components from the parts of the powder-polymer mixture (debinding process) while maintaining the structural integrity and properties of the green part (green parts refer to components that have been shaped or molded from a powder-polymer mixture but have not yet undergone sintering).

Metal/ceramic powder-polymer mixtures are commonly shaped using powder compaction or injection molding, but the polymer components must be removed before the powder component(compact) left behind is sintered to final shape and size. Traditional solvent-based debinding is slow due to temperature limits and the need to maintain part integrity. Newer methods like catalytic and wick debinding also offer low removal rates, leading to long cycle times.

A faster, more efficient debinding process is needed to boost productivity without compromising part quality.

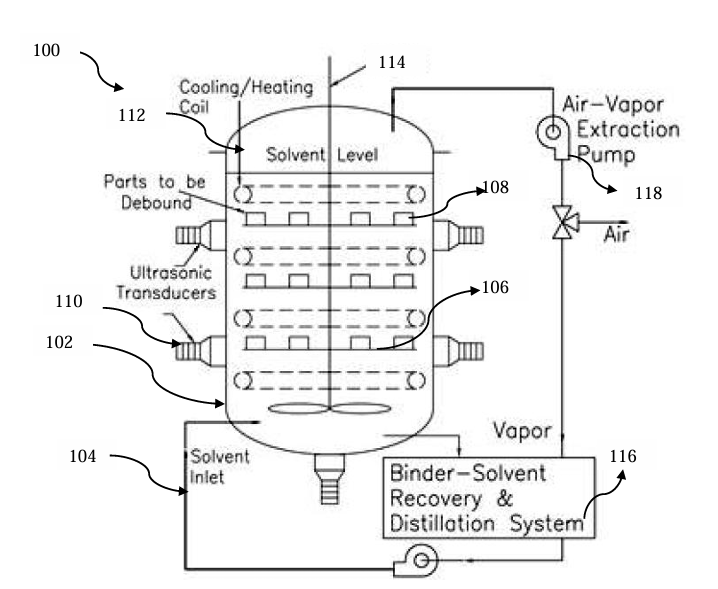

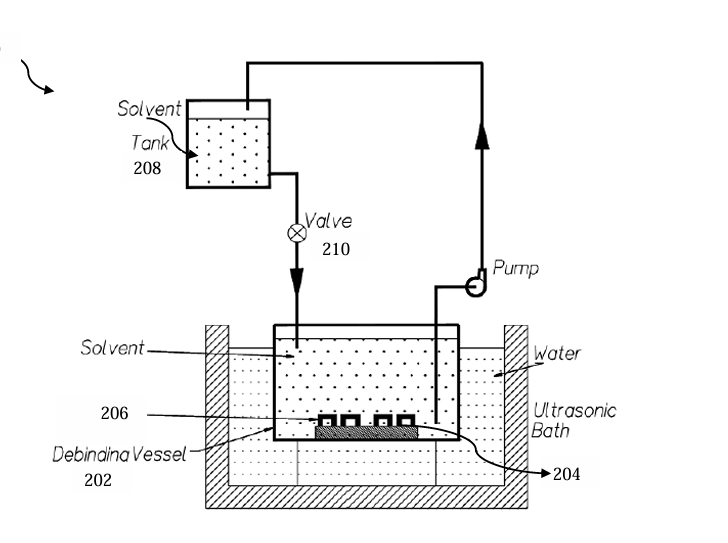

- Ultrasonic-Assisted Solvent Debinding: This innovative process accelerates polymer removal by >60% using ultrasonic excitation, significantly reducing debinding time for complex and thick-walled parts.

- Automated, Multi-Parameter Process Controllers: This apparatus is equipped with controllers for solvent temperature, level, flow rate, sonication time/cycles, and stirring velocity, ensuring consistent debinding.

- Binder-Solvent Recovery and Reuse: It has an integrated vapor recovery and distillation system that recycles solvent, improving sustainability and reducing material costs.

- Integrated Solvent Circulation System: A centrifugal or peristaltic pump and stirrer maintains continuous solvent flow at a predefined rate, efficiently removing the polymer-rich layer near the part surface and reducing debinding time.

- No Detrimental Impact on Part Integrity: It maintains properties, dimensional stability, tensile strength, and surface finish of green parts post-debinding, validated by SEM and mechanical testing.

- Specialized Apparatus with Scalability: The ultrasonic bath tanks are made of cavitation-resistant SS, integrated with ultrasonic transducers bonded to the vessel walls. The perforated trays are used for part holding, and helical coil exchangers for precise temperature control. The apparatus is designed for industrial-scale operation with large tank sizes and flow capacities.

NA

7

The proposed method and apparatus enable more efficient, safer, and environmentally friendly removal of polymers from powder-polymer mixtures. By reducing energy consumption, emission of harmful solvents, and processing time, this innovation supports sustainable manufacturing practices. It also facilitates the production of high-performance components used in healthcare, transportation, and energy sectors, ultimately enhancing quality of life and technological progress.

- Powder Injection Molding (PIM)

- Powder metallurgy

- Aerospace industry

- Automobile industry

- Healthcare/Medical device industry

Geography of IP

Type of IP

201721001516

365023